| Page: |

| Home > Beginners Tech > thnx to Benross Joe C and PhilR pics of the end result up | |||||||

1750 Posts Member #: 10190 Post Whore belgium |

11th Jan, 2017 at 09:03:37pm

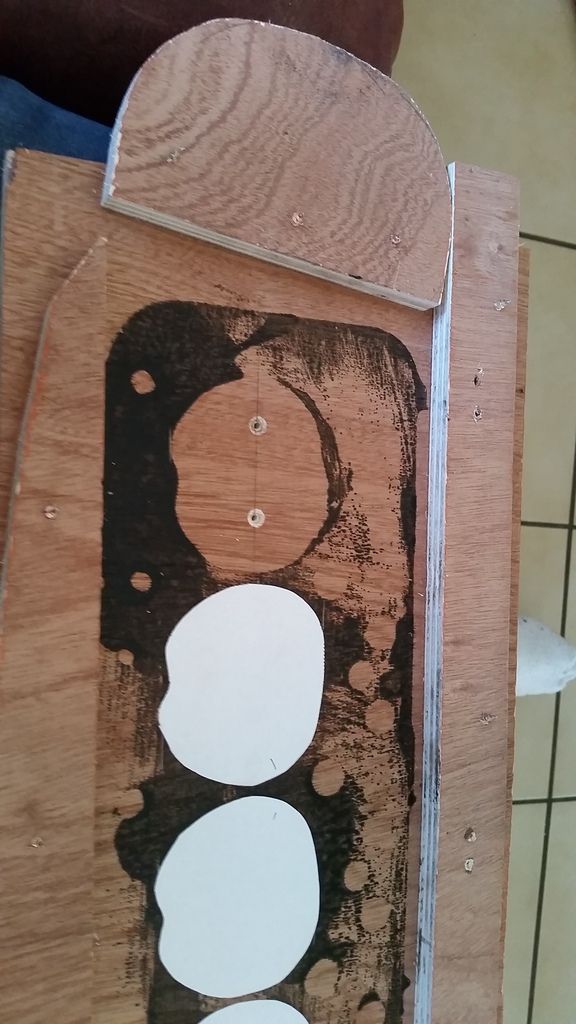

So i was thinking on what benross said about carbid bits. and then someone somewhere here i saw someone make a piston dish bigger with a router and then i also remember someone cutting the seats for under crown jets with a butterfly drill bit and saying he was amazed how soft grade the steel of the engine is... so it made me wonder about my wood bits for the router if it could cut a head. so i got an old head out took the router and a cheap wood bit... guess what. its like cutting to ( frozen) butter. so tommorow i will be making a mould and cutting my 1275 head to turbo use! Edited by Rammie2000 on 9th Mar, 2017. you can do anything if you set your mind to it...

|

||||||

|

167 Posts Member #: 11091 Advanced Member |

11th Jan, 2017 at 09:19:52pm

Pics please!

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

11th Jan, 2017 at 09:24:03pm

ill take pics of the result tomorrow. grts you can do anything if you set your mind to it...

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

11th Jan, 2017 at 09:34:38pm

Hah I suggested the router, glad it's working for you!

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

4629 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

11th Jan, 2017 at 10:13:29pm

Good luck. Hopefully it will be quicker and easier than using your dremel.

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

11th Jan, 2017 at 10:40:14pm

Edited by PhilR on 11th Jan, 2017. |

||||||

1750 Posts Member #: 10190 Post Whore belgium |

11th Jan, 2017 at 11:52:09pm

Ha yes that was it!

you can do anything if you set your mind to it...

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

12th Jan, 2017 at 10:30:35am

you can do anything if you set your mind to it...

|

||||||

|

510 Posts Member #: 1592 Smart Guy! mainland europe near ze germans |

12th Jan, 2017 at 10:44:47am

Like this ? :)

That sir, is not rust, it is the progressive mass reduction system

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

12th Jan, 2017 at 10:59:57am

Aa yes. Apparently. Only not out of free hand. Would like to have them even in size. you can do anything if you set your mind to it...

|

||||||

644 Posts Member #: 9371 Post Whore East Yorkshire |

15th Jan, 2017 at 07:23:12am

This has surprised me.... excellent work Rammie. BHP sells engines, but Torque wins races! |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

15th Jan, 2017 at 10:08:10am

Good work Rammie. That's much better than doing it freehand with a Dremel.

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

15th Jan, 2017 at 11:35:04am

On 15th Jan, 2017 PhilR said:

Good work Rammie. That's much better than doing it freehand with a Dremel. While a carbide bit would be more efficient, it would be interesting to grind a wood bit to a custom profile. Maybe one that cuts a shallower angle on the walls and another that cuts the floor flat, but has a very gradual radius into the walls. I've yet to find carbide bits that do this exactly how I imagine. you can do anything if you set your mind to it...

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

15th Jan, 2017 at 11:35:35am

On 15th Jan, 2017 madonminis said:

This has surprised me.... excellent work Rammie. you can do anything if you set your mind to it...

|

||||||

|

510 Posts Member #: 1592 Smart Guy! mainland europe near ze germans |

17th Jan, 2017 at 04:43:18am

Use a flat bottomed grinding stone ( a 20000 rpm rated one) that is well behaved for the floor. you can dress the stone to the desired profile if you want that. That sir, is not rust, it is the progressive mass reduction system

|

||||||

|

Forum Mod  1927 Posts Member #: 1761 Stalker Bristol |

17th Jan, 2017 at 01:37:23pm

This is great; ingenious solution to getting a repeatable pattern cut out of the chambers Edited by Carl S on 17th Jan, 2017. |

||||||

1750 Posts Member #: 10190 Post Whore belgium |

17th Jan, 2017 at 06:16:39pm

Working on a better mold so the result should be better 2. So all 4 can be grindee out without moving the mold. And thnx Edited by Rammie2000 on 17th Jan, 2017. you can do anything if you set your mind to it...

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

1st Mar, 2017 at 09:57:36pm

you can do anything if you set your mind to it...

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

1st Mar, 2017 at 10:00:25pm

So did take some pics. Hahaha.

you can do anything if you set your mind to it...

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

1st Mar, 2017 at 10:05:44pm

So placed the mold and fittet it with wood pieces that it sits realy tight on the head. Then used a drill trough the valve guides to centre out and painted the head to have a negative of it on the mold printed the form i wanted on a piece of paper copy it 4 times made the same centers on it gleud it onto the wood rechecked and cut it out with a dremel saw. Some sanding and here we go. The room between cambres on the mold is 4 mm thinner than it will be on the head ( the guide that follows it is 2 mm wider than the bit on the router guide plate) hope it makes sense in my crappie English. you can do anything if you set your mind to it...

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

1st Mar, 2017 at 10:16:58pm

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

2nd Mar, 2017 at 10:02:03am

brilliant! |

||||||

1750 Posts Member #: 10190 Post Whore belgium |

9th Mar, 2017 at 08:05:39pm

you can do anything if you set your mind to it...

|

||||||

| Home > Beginners Tech > thnx to Benross Joe C and PhilR pics of the end result up | |||||||

|

|||||||

| Page: |

was it this, Rammie?

was it this, Rammie?