| Page: |

| Home > Help Needed / General Tech Chat > Centre Main Strap Issues | |||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

14th Apr, 2015 at 09:29:35am

Morning Guys

|

||||||

190 Posts Member #: 8935 Advanced Member netherlands |

14th Apr, 2015 at 09:50:46am

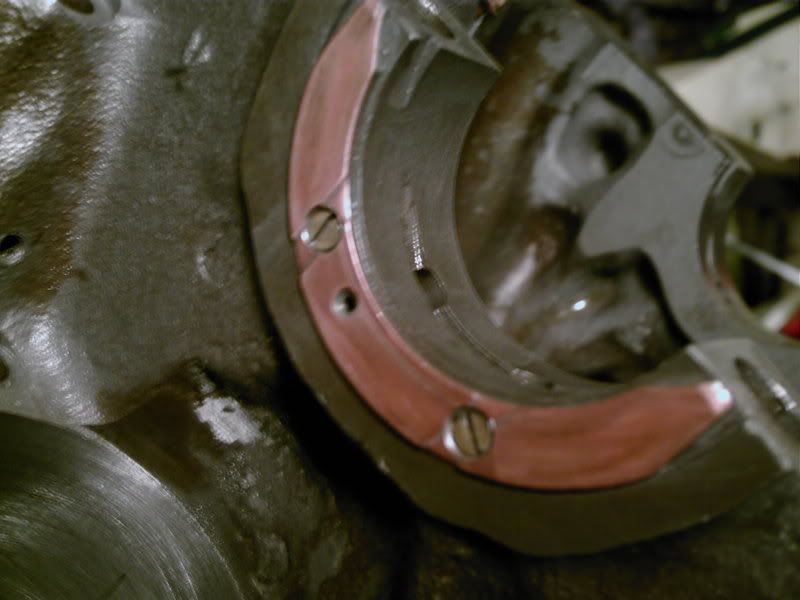

looks like they took off to much of centre main cap??!! Edited by clubbie70 on 14th Apr, 2015. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

14th Apr, 2015 at 10:15:37am

Nothing wrong with what you have. It's just that in cutting down the cap to the height of the bolt shoulder removes the thrust washer locating slot.

Edited by Paul S on 14th Apr, 2015. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

14th Apr, 2015 at 10:25:23am

Nope, that's right for a small-bore cap. You don't have to take so much off with a 1275 cap, so the original slot doesn't get machined away.

Edited by PhilR on 14th Apr, 2015. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

14th Apr, 2015 at 10:48:29am

On 14th Apr, 2015 Paul S said:

Nothing wrong with what you have. It's just that in cutting down the cap to the height of the bolt shoulder removes the thrust washer locating slot. Usually we get around that problem by using a wide strap and cutting a new slot in the cap.

I recall that someone once said that they had problems with the sharp edge on the cap cutting into the thrust washer tab. I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

|

9258 Posts Member #: 123 Post Whore Betwix Harrogate and York |

14th Apr, 2015 at 11:42:26am

This seems the standard way that 998 centre main straps are machined. If you have a light clutch you'll probably get away with it.

Fastest 998 mini in the world? 13.05 1/4 mile 106mph

On 2nd Jan, 2013 fastcarl said:

the design shows a distinct lack of imagination, talk about starting off with a clean sheet of paper, then not bothering to fucking draw on it,lol On 20th Apr, 2012 Paul S said:

I'm mainly concerned about swirl in the runners caused by the tangential entry. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

14th Apr, 2015 at 12:39:07pm

Wil the think his issue is that the strap he has is too thin so the thrusts are flush when it's fitted. Carl did the same as yours and added some dowls into the strap to locate the tang on the thrust I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

14th Apr, 2015 at 09:01:20pm

Ill upload another photo and you guys can see

|

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

14th Apr, 2015 at 09:43:59pm

|

||||||

1030 Posts Member #: 1291 Post Whore Suffolk / Birmingham |

15th Apr, 2015 at 05:54:37am

Like I said in your build thread. file a slot in the block and put the thrusts in the other way up. Quicker than making a new strap. |

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

15th Apr, 2015 at 09:04:29pm

Thanks Slater

|

||||||

7765 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

17th Apr, 2015 at 07:11:01am

File a slot in the block. Listen to what people suggest! On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

17th Apr, 2015 at 07:51:11am

I'm taking Paul's Option.

On 17th Apr, 2015 Vegard said:

File a slot in the block. Listen to what people suggest! |

||||||

7765 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

17th Apr, 2015 at 08:42:18am

You could file it at 12 degrees if you want to....

On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

10022 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

17th Apr, 2015 at 08:48:53am

Other option would be to drill and screw the thrusts to the block & cap. If something is worth doing, it's worth doing half of. |

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

17th Apr, 2015 at 11:15:26am

How would a slot in a strap weaken it?

On 17th Apr, 2015 Vegard said:

You could file it at 12 degrees if you want to.... You prefer weakening the strap  |

||||||

10022 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

17th Apr, 2015 at 11:59:29am

If something is worth doing, it's worth doing half of. |

||||||

10022 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

17th Apr, 2015 at 12:00:00pm

Not if they are counter sunk enough. If something is worth doing, it's worth doing half of. |

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

17th Apr, 2015 at 02:32:21pm

That looks a good idea john no more spun bearings but how do you drill and tap them? |

||||||

10022 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

17th Apr, 2015 at 02:49:42pm

I got Carl @ Force Racing to do mine. But I see no reason why you couldn't do it yourself.

If something is worth doing, it's worth doing half of. |

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

17th Apr, 2015 at 03:20:12pm

Thanks john I'll take a look into it giving me some food for thought |

||||||

| Home > Help Needed / General Tech Chat > Centre Main Strap Issues | |||||||

|

|||||||

| Page: |