| Page: |

| Home > Technical Chat > Progressive or linear coilover springs | |||||||

1434 Posts Member #: 8466 Post Whore Mansfield |

11th Nov, 2014 at 10:33:41pm

What's peoples thoughts and recommendations for 1.9 coilover springs. Some people supply progressive, others linear. I plan on using protech front and rear coilovers. Car will weight about 510-515kg 35-65% rear-front. I have already bought 100lb linear rear springs (rear ARB)

Class C 3rd Place Avon 2011 14.18 @101mph |

||||||

|

4018 Posts Member #: 1757 Back to Fucking Tool status Swindon |

12th Nov, 2014 at 04:30:00am

When I spec'd to protech for my coilovers I was recomended 265/340 progressive with a vehicle weight of around 550kg.

Drives

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

12th Nov, 2014 at 05:26:02am

i ran the original progressives on the back , i think they were around 90 lbs , way too soft. now have 150 lbs linear , still too soft i think .car weighs around 650 kg . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

1434 Posts Member #: 8466 Post Whore Mansfield |

12th Nov, 2014 at 05:50:27am

I must admit the 100lb rears do feel very soft, compared to the standard subframe setup with red cones. If I stand on the rear boot lid lip the wheels touch the arch and the top KAD calliper hits the boot floor lip.

Edited by alaskanow0 on 12th Nov, 2014. Class C 3rd Place Avon 2011 14.18 @101mph |

||||||

3074 Posts Member #: 1348 Post Whore wakefield West Yorks |

12th Nov, 2014 at 06:31:18pm

I went through all this when messing with mine. Never really got anything sorted but came to the same conclusion as you that it would be trial and error.

|

||||||

690 Posts Member #: 9962 Post Whore |

13th Nov, 2014 at 11:56:18am

The main problem with coilovers on a Mini is that the std cone sprung car is non linear, very aggressively at the front and less so at the rear.

Edited by Aubrey_Boy on 28th Nov, 2014. |

||||||

1434 Posts Member #: 8466 Post Whore Mansfield |

13th Nov, 2014 at 05:41:46pm

Thankyou for your detailed explanation. I've made a decision to ditch the front coilover setup, as per my build thread. This is partly down to the lack of weight saving, but mainly down to concerns of how they will perform. Having spoken to a few people, I think cones are probibly a safer bet. I'm concerned about lack of droup, harsh ride etc. on coilovers.

Edited by alaskanow0 on 13th Nov, 2014. Class C 3rd Place Avon 2011 14.18 @101mph |

||||||

690 Posts Member #: 9962 Post Whore |

14th Nov, 2014 at 08:36:25am

Just my opinion... As far as the 'best' set up goes it would have to be a qualified 'best'

Edited by Aubrey_Boy on 28th Nov, 2014. |

||||||

6745 Posts Member #: 828 Post Whore uranus |

14th Nov, 2014 at 09:33:01am

i suppose the thing to d on the rear , is move the top coilover mount forward to the bulkhead . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

690 Posts Member #: 9962 Post Whore |

14th Nov, 2014 at 10:10:56am

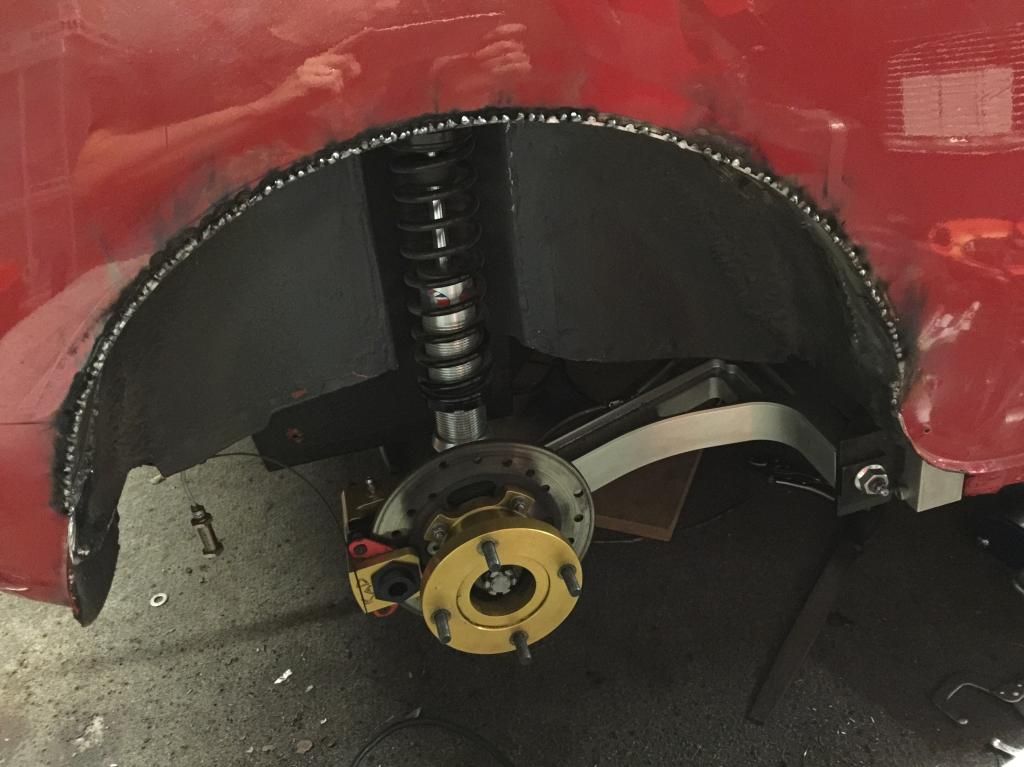

And as if by magic Edited by Aubrey_Boy on 28th Nov, 2014. |

||||||

1434 Posts Member #: 8466 Post Whore Mansfield |

14th Nov, 2014 at 10:50:19am

Ok I think I'm following this. I'm I right in thinking the coilover has to be mounted in relation to the direction of travel of the bottom arm.

Edited by alaskanow0 on 14th Nov, 2014. Class C 3rd Place Avon 2011 14.18 @101mph |

||||||

690 Posts Member #: 9962 Post Whore |

14th Nov, 2014 at 11:10:57am

Moving the top mount up 25mm will make it very slightly worse but likely to be tiny in reality

Edited by Aubrey_Boy on 28th Nov, 2014. |

||||||

1434 Posts Member #: 8466 Post Whore Mansfield |

14th Nov, 2014 at 09:52:37pm

Thanks for all your help. I'm still a little confused why the different angle makes such a difference. I've try to search online, but can't fine any thing that explains it.

Edited by alaskanow0 on 14th Nov, 2014. Class C 3rd Place Avon 2011 14.18 @101mph |

||||||

|

Forum Mod  4828 Posts Member #: 154 Post Whore Midlands |

14th Nov, 2014 at 10:30:13pm

If you need any decent pics or anything of how i've cobbled mine together just shout.

On 20th Oct, 2015 Tom Fenton said:

Well here is the news, you are not welcome here, FUCK OFF. |

||||||

6745 Posts Member #: 828 Post Whore uranus |

15th Nov, 2014 at 08:01:29am

it sounds like what paul h did with his donuts up against the seat rail ,was a good idea .

Edited by robert on 15th Nov, 2014. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

15th Nov, 2014 at 08:53:12am

This is a great thread. Excellent information.

In the 13's at last!.. Just |

||||||

2974 Posts Member #: 10749 Post Whore lowestoft suffolk |

15th Nov, 2014 at 11:19:38am

On 15th Nov, 2014 robert said:

it sounds like what paul h did with his donuts up against the seat rail ,was a good idea . http://www.turbominis.co.uk/forums/index.php?p=vt&tid=447470 On 24th Oct, 2015 jonny f said:

Nothing gets past Dave lol NOTHING GETS PAST ME!!

1/4 mile 14.7 @ 96mph 12psi boost Showdown class A 2nd place 18.6 @ 69mph |

||||||

690 Posts Member #: 9962 Post Whore |

16th Nov, 2014 at 09:34:34am

The thing we are concerned about is called motion ratio, that is the relative motion of the wheel centre in a pure vertical sense versus the displacement of the coilover (spring travel if you like) along the coilover axis.

Edited by Aubrey_Boy on 28th Nov, 2014. |

||||||

| Home > Technical Chat > Progressive or linear coilover springs | |||||||

|

|||||||

| Page: |