| Page: |

| Home > Show Us Yours! > My 1293 clubby turbo build | |||||||

|

313 Posts Member #: 9367 Senior Member Derby |

18th Dec, 2012 at 06:40:51pm

Just thought I'd start a thread seeing as I have been gathering bits for a while and keep asking lots of questions.

|

||||||

562 Posts Member #: 9285 Post Whore Oxfordshire |

18th Dec, 2012 at 06:51:34pm

Lovely looking clubman mate. And where abouts are you from? This will help with RR recommendations. My build thread: http://www.turbominis.co.uk/forums/index.php?p=vt&tid=454802

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

18th Dec, 2012 at 06:53:59pm

Thanks. I'm from derby but have tried a few places in the midlands. |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

18th Dec, 2012 at 06:56:38pm

Car looks great. There's John sleath between Doncaster and Rotherham. On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

9th Jan, 2013 at 08:43:29pm

Well I'm making some progress. I've got myself a benross head, one of matty's high flowing manifolds and had my t3 oil feed pipe altered to suit the larger banjo bolt on the gt17.

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

10th Feb, 2013 at 10:21:03am

Bit of progress to report but no photos yet. Sorry now for all those hoping for some pictures.

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

19th Feb, 2013 at 09:55:41pm

Got my car back from the body shop tonight. Had a bulkhead box put in for extra turbo clearance and just incase I decide to go bigger later.

|

||||||

|

104 Posts Member #: 10210 Advanced Member Durban, South Africa |

20th Feb, 2013 at 11:37:37am

Beautiful looking clubby, looks quick and mean in that pic. Life is always a matter of opinion and quite frankly, no ones opinion really matters. |

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

14th Mar, 2013 at 12:35:30pm

Well I picked up my short engine from Steve (Benross) on Monday night and although it looked lovely and made me want to crack on immediately I've not had the opportunity to get in the garage since.

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

1st Apr, 2013 at 12:04:47pm

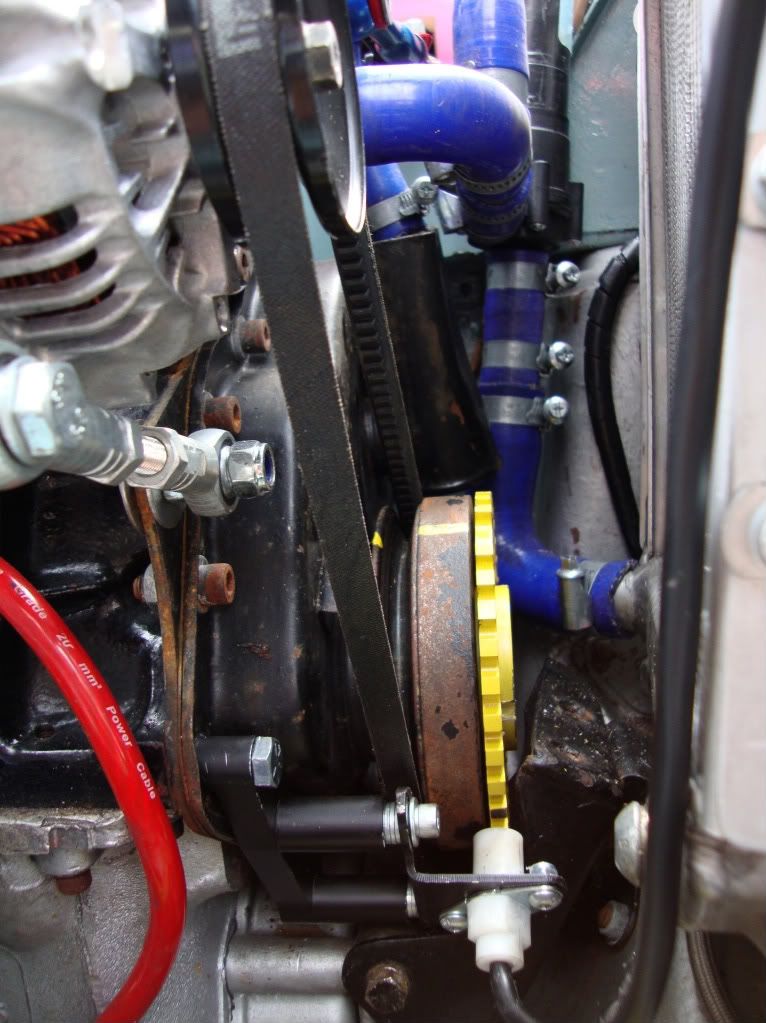

So this is where it's at right night. Waiting on my turbo back from having actuator bracket moved and an inlet stump welded on. Everything else is bolted on.

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

1st Apr, 2013 at 04:58:23pm

Also fitted a rose jointed turnbuckle to adjust the alternator. Need to look at lengths and get a belt!

|

||||||

359 Posts Member #: 8931 Senior Member Herefordshire |

1st Apr, 2013 at 07:28:00pm

Great looking build. I really like that lower rose jointed alternator bracket! Is it custom made or bought off the shelf? |

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

1st Apr, 2013 at 07:37:52pm

It's kind of off the shelf I found the shaft on eBay and asked them to make me one up with LH and RH rose joints. It cost me about £15 in total so not bad and loads of lengths available.

|

||||||

216 Posts Member #: 9845 Senior Member Staffordshire |

1st Apr, 2013 at 07:45:45pm

lovely looking mini mate!

998 t2 ongoing project. |

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

1st Apr, 2013 at 07:53:20pm

Where are you smit360? |

||||||

216 Posts Member #: 9845 Senior Member Staffordshire |

1st Apr, 2013 at 07:57:10pm

In Burton, just down the 38. 998 t2 ongoing project. |

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

1st Apr, 2013 at 08:19:53pm

On 1st Apr, 2013 bakker110 said:

It's kind of off the shelf I found the shaft on eBay and asked them to make me one up with LH and RH rose joints. It cost me about £15 in total so not bad and loads of lengths available. Should have lots of adjustability. I got 110 to 140mm. I have heard halfords is a good place for belts so ill have a look there. Mate I had done this,, and it left me on an AA Truck!! As it lets the Alternator move / flex so then it cracks the water pump, have a look at my build page. I just went back to the OE one and it was fine. I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

1st Apr, 2013 at 08:25:55pm

Are you sure it's that likely? How did it flex the water pump?

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

7th Apr, 2013 at 06:55:12pm

Right a bit of progress today.

|

||||||

|

104 Posts Member #: 10210 Advanced Member Durban, South Africa |

7th Apr, 2013 at 07:29:27pm

Looking good mate, I like the whole black and silver colour choice for the engine ( even though you're loosing about 10bhp by it not being red Life is always a matter of opinion and quite frankly, no ones opinion really matters. |

||||||

359 Posts Member #: 8931 Senior Member Herefordshire |

7th Apr, 2013 at 08:54:33pm

Thinking about the flex with the rose jointed steady I can see Simons concerns with the problem being that the spherical joints are intended to give a large axis of movement, but providing you put in some of the small spacers that stop the spherical joint moving from side to side and allowing for any lateral flex I can't see a problem. I understand that in the following link, these spacers are intended for misalignment issues, but something similar that holds the outside of the joint in a fixed position could be easily turned out in a lathe and would surely stop any flex? Just my thoughts :)

|

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

7th Apr, 2013 at 08:57:28pm

Yes it is. I just had the banjo drilled out for the gt17 banjo bolt and a new oil gallery groove put in. |

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

7th Apr, 2013 at 09:30:08pm

Hi there mate. First of all I don't want you to think that I am slagging off your work! I did the same thing when I first built mine.

I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

|

104 Posts Member #: 10210 Advanced Member Durban, South Africa |

8th Apr, 2013 at 10:56:42am

Thanks for the clarification, I think I'm gonna stick to standard as it's my daily and I really don't want to be sat at the side of the road.

Life is always a matter of opinion and quite frankly, no ones opinion really matters. |

||||||

|

313 Posts Member #: 9367 Senior Member Derby |

9th Apr, 2013 at 10:22:07am

I will have a look at it then and maybe swap it back. Is the water pump blanking plate thinner than a water pump?

|

||||||

| Home > Show Us Yours! > My 1293 clubby turbo build | |||||||

|

|||||||

| Page: |

).

).