| Page: |

| Home > General Chat > Any Plumbers on here? | |||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

16th Nov, 2011 at 01:09:54am

Been messing with my central heating over the last week or so, replacing some existing rads and also adding a couple of new ones.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

2057 Posts Member #: 9252 Post Whore Cleethorpes |

16th Nov, 2011 at 07:13:48am

thats how it should be tom like you say the air cant vent you should be fine with that mod. Edited by wng691s clubby on 16th Nov, 2011. Done now needs redoing lol |

||||||

6752 Posts Member #: 828 Post Whore uranus |

16th Nov, 2011 at 08:48:38am

prob done this tom but , has the pump itself got a bleed on it ? Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

2057 Posts Member #: 9252 Post Whore Cleethorpes |

16th Nov, 2011 at 08:57:24am

Done now needs redoing lol |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

16th Nov, 2011 at 09:36:42am

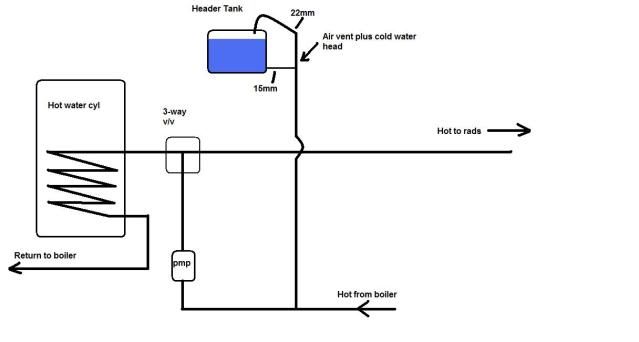

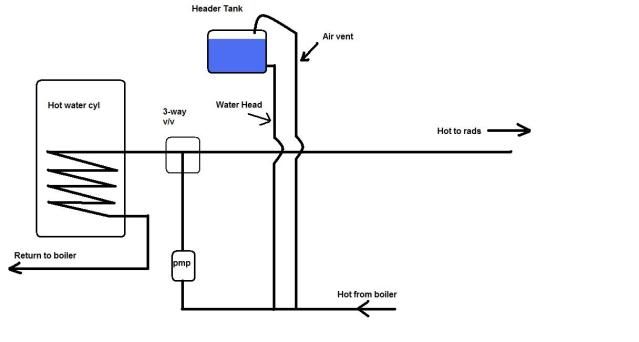

The conventional way is to take the cold feed (the one you've labelled as Water Head) to the cold side of the boiler, ideally as close as possible to the boiler, but if you want to minimise the run, it could go into the return from the HW tank (bottom left of your sketch). Schrödinger's cat - so which one am I ??? |

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

16th Nov, 2011 at 11:03:26am

Gents

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

16th Nov, 2011 at 11:12:13am

Could the pump actually be drawing air in through the vent?

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

16th Nov, 2011 at 11:16:28am

I don't think it is Paul although theory works.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

16th Nov, 2011 at 11:35:14am

pull all the TRVs off the valves to make sure they are not causing an issue; I had this with part of the circuit in the 1st floor and it turned out to be a faulty trv |

||||||

2057 Posts Member #: 9252 Post Whore Cleethorpes |

16th Nov, 2011 at 11:40:30am

after a fresh refill it takes a couple of days to get all the air out beacause of the amount of oxygen molecules in the fresh water, normally your heating water is kind of stagnent, but doing your mod will make it easyer to get rid of the enitial large amouts of air and stop the gargling but youll need to nip around the rads a few time to get rid of the little bits left Done now needs redoing lol |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

16th Nov, 2011 at 12:02:13pm

On 16th Nov, 2011 Tom Fenton said:

I'm going to give my mod a try, perhaps your idea is a better one Rod with where to introduce it. However some internet pictures show and state that the cold feed should be as close as poss to the expansion. Things have changed, Interesting article here http://www.pumptool.co.uk/Position.html The two systems I installed (many years ago) I used option 2, my current house is option 3, you appear to have option 5 or 6. EDIT - might be worth seeing if your boiler manufacturer has a website and some recommendations on feed/vent specific to that boiler. Edited by Rod S on 16th Nov, 2011. Schrödinger's cat - so which one am I ??? |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

16th Nov, 2011 at 12:07:39pm

Tom. Have u got an a jet? Looks like a little cyinder with 2 pipes from above and 2 from below and 1 of those wil go into the pump. It will be in the airing cubard 13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

16th Nov, 2011 at 12:07:43pm

Tom. Have u got an a jet? Looks like a little cyinder with 2 pipes from above and 2 from below and 1 of those wil go into the pump. It will be in the airing cubard 13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

|

8215 Posts Member #: 90 Post Whore Somewhere around Swindon |

16th Nov, 2011 at 12:56:15pm

we were right in the middle of doing the same to our new house Tom new rads moving others ect and we have what looks like the identical setup, not in a position to re-fill and bleed my sysstem yet Crystal Sound Audio said:

Why wolfie...you should have your name as Fuckfaceshithead ! "A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools."-Douglas Adams |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

17th Nov, 2011 at 05:25:13pm

the separate vent and feed pipe is allways the better option so change it if you need to, make sure there before the pump and that there is not any sort of airjet. if there is remove it else ull have problems.

13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

2057 Posts Member #: 9252 Post Whore Cleethorpes |

17th Nov, 2011 at 05:59:46pm

Any joy with this Tom or is it a job for the weekend Done now needs redoing lol |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

17th Nov, 2011 at 06:22:39pm

I designed and installed the system here, 2 heat sources, 3 pumps, 4 zones and 20 rads.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

17th Nov, 2011 at 06:51:43pm

Paul the 1 thing to watch out for is old maintenance valves like to leak when they get used. 13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

478 Posts Member #: 9269 Senior Member Rotherham |

17th Nov, 2011 at 06:57:50pm

Tom if you would like me to call take a look give me a pm with your mobile number

Craig

|

||||||

9812 Posts Member #: 332 Resident Cylinder Head Modifier Mitsi Evo 7, 911, Cossie. & all the chavs ...... won no problem |

17th Nov, 2011 at 07:49:53pm

now theres an offer tom get the kettle on

|

||||||

1713 Posts Member #: 8480 MS Paint flat cap champion & Morris Ital Lover From Sheffield now live in York tha noz |

17th Nov, 2011 at 08:28:30pm

As eden say above, if that lot is in the loft and the highest rads are in the rooms below, then the top line into the cylinder/3 port valve/flow to rads is the top part of the system and should have a means to vent usually either manual or an auto air vent, an airlock anywhere in the system causes much the same problems and the pump generally wont shift it in an open vent system. From as you describe when all started up the pump runs and is generally noisy, bleed the pump and it all quietens down and then after seconds/mins the pump speed/noise picks up and makes the noises you descibe-open vent microbore systems are a twat for it

Edited by oli79 on 17th Nov, 2011. On 18th Oct, 2013 apbellamy said:

I am feeling particularly BACish today. On 5th Oct, 2014 Shauna said:

What that's crazy, you go commando hahaha! How heavy is your helmet  ? ? The Morris Ital assassin! |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

10th Dec, 2011 at 09:37:26pm

Topic resurection.

Edited by Sprocket on 10th Dec, 2011. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

11th Dec, 2011 at 10:01:36am

Sproket dont fit 1! There useliss.

13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

11th Dec, 2011 at 11:03:05am

Not sure how adding a slightly larger 'chamber' to an already existing similarly piped layout can cause the cold water feed to scale over Edited by Sprocket on 11th Dec, 2011. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

11th Dec, 2011 at 11:14:59am

I know wat ur saying mate and I agree, but I rip them out time after time because they cause problems.

13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

| Home > General Chat > Any Plumbers on here? | |||||||

|

|||||||

| Page: |

If that is the case, then the cold feed as it is now would scale over anyway? I'm not altering the cold feed pipework, just replacing the tee on the flow/ vent pipe.

If that is the case, then the cold feed as it is now would scale over anyway? I'm not altering the cold feed pipework, just replacing the tee on the flow/ vent pipe.