| Page: |

| Home > A-Series EFI / Injection > Staged Injection | |||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

4th Oct, 2010 at 01:32:46pm

Here is my first attempt at modifying the MPI inlet manifold I am using to utilise a secondary set of injectors, for staged injection, once I have my Turbo charged engine.

’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

4th Oct, 2010 at 03:46:06pm

The angle of the second ones is a lot worse than I was expecting from your previous descriptions but they are in approximately the same location (which I wasn't expecting) so transit times should be similar.

Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

5th Oct, 2010 at 07:45:38am

On 4th Oct, 2010 Rod S said:

..... Have you run it up through the RPM / load range on the original settings on just the angled injectors to see if it reverts back to its previous AFRs on just the angled injectors at high loads ??? No, I’ve not tried this. I’ll swap the injectors over and try it this evening. ’77 Clubman build thread

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

7th Oct, 2010 at 06:37:38pm

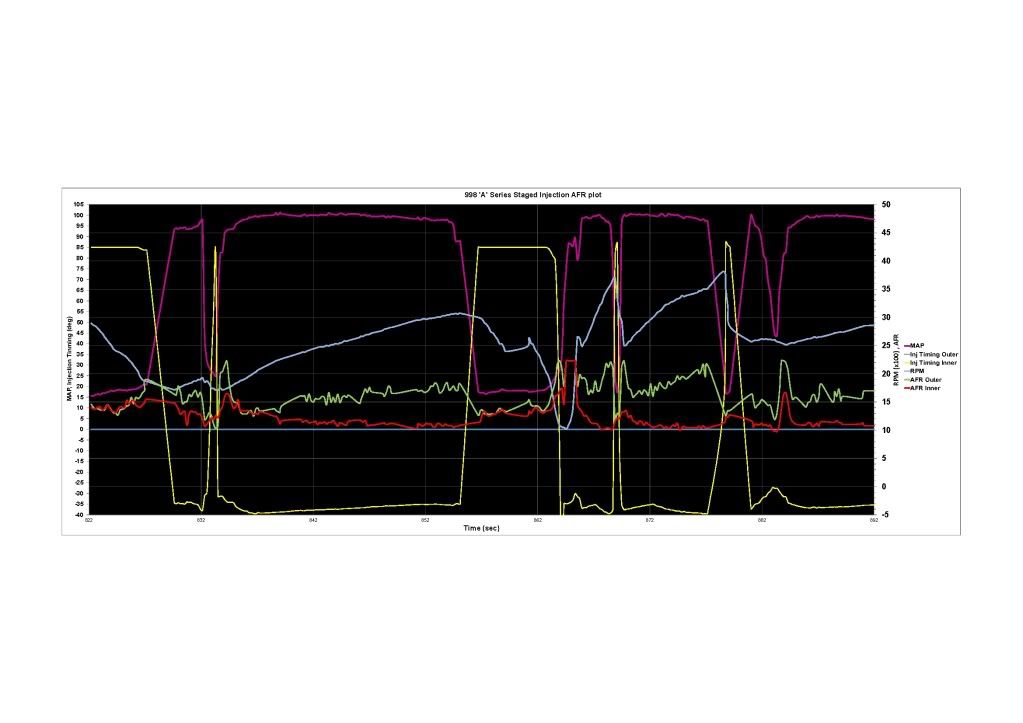

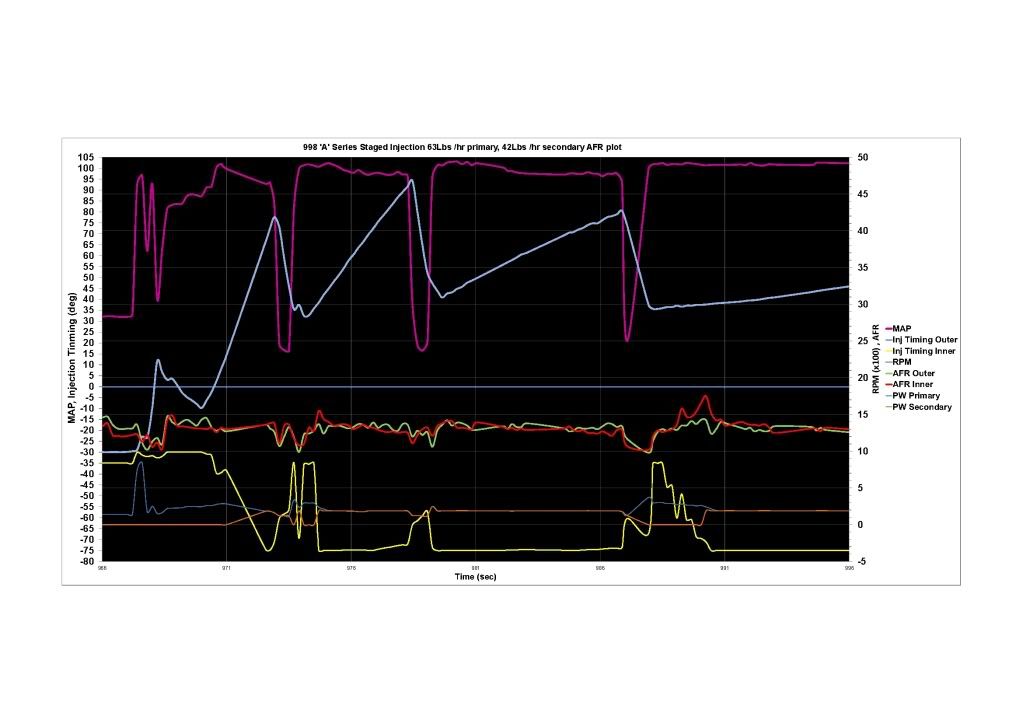

As per the above post, here is a part of the log taken.

’77 Clubman build thread

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

7th Oct, 2010 at 09:03:02pm

Graham,

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

8th Oct, 2010 at 01:25:29pm

The 42 Lbs/ hr injectors I am using are these:

’77 Clubman build thread

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

8th Oct, 2010 at 02:30:30pm

Staging should behave as described in your first test on the JimStim. Pulse widths should be the same for all 4 channels only if you have the same VE in tables 1 and 2 (or if you only use table 3). The pulse width will simply be scaled with respect to the injector sizes: if you have the same size for primary and secondary then the pulse width will be halved, if the secondary are twice as big the pulse width will be divided by 3 and so forth (ratio of primary over primary+secondary). Of course this scaling is done only on the effective pulse width which doesn't include the dead time (opening time).

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

8th Oct, 2010 at 05:22:22pm

Hopefully the MSQ is attached... ’77 Clubman build thread

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

10th Oct, 2010 at 06:30:23pm

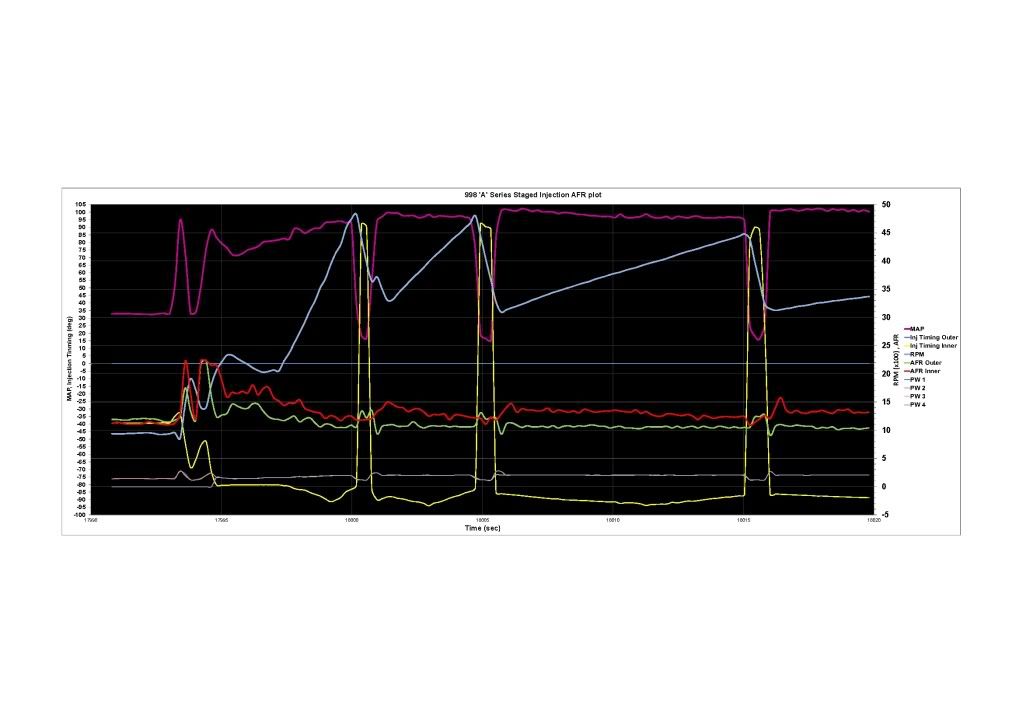

After a bit of testing with the megasquirt on the JimStim, I’ve recreated the problem I was seeing on the car when I first tried setting staged injection.

’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

11th Oct, 2010 at 10:19:50am

It's a bit difficult to read the scales and legend on that plot but it looks like you're gaining (ie, going week) by 2.5AFR on the inners when staging cuts in.

Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

11th Oct, 2010 at 12:24:13pm

On 11th Oct, 2010 Rod S said:

It's a bit difficult to read the scales and legend on that plot but it looks like you're gaining (ie, going week) by 2.5AFR on the inners when staging cuts in. Yes – 2.5 – 3AFR when staging is enabled. On 11th Oct, 2010 Rod S said:

That sort of implies from a crude mechanical view that the second injector is bouncing its fuel off the innerwall of the manifold and aiming it at the outer cylinder. If so, I doubt you'll correct it with timing. I think it is more down to not knowing where to set the timing when staging is on. I have -95Deg (tick over) timing for the injectors in the side bosses and -35deg for the injectors in the MPI bosses I started at -95, which appears to be putting a big portion of the fuel from injectors in the MPI bosses into the outer cylinders. On the latest run, I have changed the timing to around -50 and this has actually over cooked it. I’m now lean on the outer cylinders by about 1.5AFR On 11th Oct, 2010 Rod S said:

But the yellow trace confuses me - if its INJ timing outer (I think that's what I can read) then there must surely be an error on the bottom row of your timing table as it swings wildly when MAP hits near zero on a gearchange ??? The yellow trace is injection timing 2 – Inner cylinders. The bottom row of the table I set with a load bin of 25KPa – All the fields on this row are set with + injection figures – 75Deg – 95 from 1000rpm through to 6000. I found that this helps keep the AFR’s even. I also have the bottom row of my fuel VE tables set with a load bin of 25KPa and fairly high figures ( roughly equivalent to the figures in the 70KPa row). It was done to smooth out the AFR’s, that way I was not seeing lean outs at every gear change. If’ it’s not necessary or detrimental to the running of the engine, I’ll remove it. On 11th Oct, 2010 Rod S said:

Also you need some more AE at low RPMs (first active part of the log). I have changed the primary injectors to the 63Lbs/hr ones and I’m working on getting things set. ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

11th Oct, 2010 at 12:42:12pm

On 11th Oct, 2010 Graham T said:

On 11th Oct, 2010 Rod S said:

But the yellow trace confuses me - if its INJ timing outer (I think that's what I can read) then there must surely be an error on the bottom row of your timing table as it swings wildly when MAP hits near zero on a gearchange ??? The yellow trace is injection timing 2 – Inner cylinders. The bottom row of the table I set with a load bin of 25KPa – All the fields on this row are set with + injection figures – 75Deg – 95 from 1000rpm through to 6000. I found that this helps keep the AFR’s even. I also have the bottom row of my fuel VE tables set with a load bin of 25KPa and fairly high figures ( roughly equivalent to the figures in the 70KPa row). It was done to smooth out the AFR’s, that way I was not seeing lean outs at every gear change. If’ it’s not necessary or detrimental to the running of the engine, I’ll remove it. I misread the legend as outers, not inners, but the thing I don't understand is why it leaps from an obviously negative range to suddenly spike massively positive when the throttle is closed for a gearchange. The actual effect should be minimal as, by definition, when MAP drops that low no power is required but if there is any effect, it seems to be on the outer cylinders. Can you post a picture of the timing table, I can't understand from your description why it shoots so high positive. Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

11th Oct, 2010 at 01:20:41pm

’77 Clubman build thread

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

11th Oct, 2010 at 01:41:28pm

I"m sorry I didn't get back to you before or have a look at the msq. But you seem to have solved the issue.

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

11th Oct, 2010 at 02:01:33pm

Jean, I’ve just found that problem…

On 11th Oct, 2010 jbelanger said:

Also, with staging, you will likely want to have some sort of discontinuity in your timing table at the point where you turn staging on. Granted there aren't many points in the table but if you can have a column just before the switching point and one just at the switching point then you could play with the staged and unstaged timing relatively independently. Jean Staging is set to 3000 rpm but when the engine is turning at, say 2750, it is working out settings partly based on the values in the 3000rpm column. So for example, although staging is not active, I’m guessing the ms is calculating figures based on the differnces between the 2000rpm and 3000rpm column, hence giving timing figures which are messing up the AFR’s until the staging threshold is reach. This may be something else I’ve got wrong in the setup, but I set the second staging parameter for MAP, set to go on above 75KPa with a Hysteresis of 10KPa. Secondary staging logic set to AND. (Which I take to mean that if the first staging parameter is above xx AND the second staging parameter is above xx, activate staging?) As soon as I power cycled the MS, I started getting resets on the MS. The only way to stop the resets is to turn off the second staging parameter and power cycle. ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

11th Oct, 2010 at 02:10:13pm

Not withstanding Jean's comments above, I'm really surprised the four bottom right cells work for your fuelling.

Schrödinger's cat - so which one am I ??? |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

11th Oct, 2010 at 03:20:57pm

Did you really get resets or were those error messages? If the fuel pump output turns on and off every second and RPM goes to 65535 then this is a configuration error.

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

11th Oct, 2010 at 04:27:42pm

On 11th Oct, 2010 jbelanger said:

...If the fuel pump output turns on and off every second and RPM goes to 65535 then this is a configuration error... Jean Yep, definately got this. I'll test it again in a bit and see what the error is in mini term. ’77 Clubman build thread

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

11th Oct, 2010 at 09:20:18pm

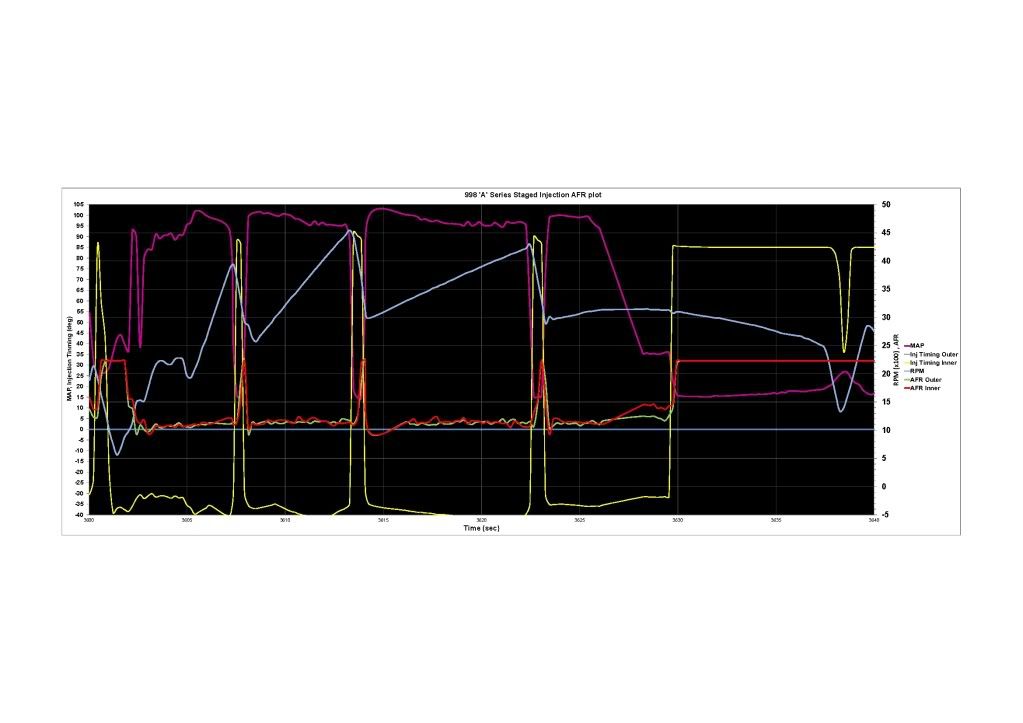

The reset error was to do with not having staging gradual transition turned on. Specifically no staging transition events, which you can only specify by turning on the staging gradual transition option.

On 11th Oct, 2010 Rod S said:

Not withstanding Jean's comments above, I'm really surprised the four bottom right cells work for your fuelling. Obviously it's what I saw on the yellow trace and if it works, I just don't understand why. But you are he first on this (staged siamese) so keep it going..... Just to see what happened, I set the bottom row of injection timing table 2 to the same figures as the 30KPa row, expecting to be able to post a log showing radically different AFR’s between inner and outer cylinders. But I cannot post that log because it never made the slightest difference. So, that row can disappear…

On 11th Oct, 2010 jbelanger said:

Also, with staging, you will likely want to have some sort of discontinuity in your timing table at the point where you turn staging on. Granted there aren't many points in the table but if you can have a column just before the switching point and one just at the switching point then you could play with the staged and unstaged timing relatively independently. Jean As per Jean’s suggestion I now have a column in the timing and Fuel VE tables, just before switching occurs. Although it helps, I’m still getting lean out’s on the inner cylinders: due to the big swing in Injection timing required once the staged injectors go active. ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

11th Oct, 2010 at 11:03:09pm

Well that's looking a lot better.

Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

12th Oct, 2010 at 07:59:33am

Could that deviation at the last gear change be anything to do with the lower speed of acceleration of the engine once in 4th gear? The engine is taking longer to go through the staging transition. ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

12th Oct, 2010 at 08:16:44am

On 12th Oct, 2010 Graham T said:

Could that deviation at the last gear change be anything to do with the lower speed of acceleration of the engine once in 4th gear? The engine is taking longer to go through the staging transition. Could be - I hadn't spotted the RPM droped just below 3000 on that 3-4 gear change whereas it didn't on the previous 2-3 change. Looks like it also dropped just below 3000 on the 1-2 change and there is also a slight weak blip, not as pronounced probably, as you say, because the acceleration rates are different. Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

12th Oct, 2010 at 08:30:27am

I've just changed the Hysteresis on the staging to 1rpm and set the last "unstaged columns" in injection timing and fuel VE tables to 2999rpm, with staging coming in at 3000rpm. Although it's on a relatively cold engine, 60deg (about 103WUE%) the inner cylinder lean out is gone. It was enough to cause a stutter as the engine went through the Staging Transition - even when under warm up enrichment. That stutter is now gone.

’77 Clubman build thread

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

20th Nov, 2010 at 08:39:03pm

Just a quick update on this...

’77 Clubman build thread

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

21st Nov, 2010 at 09:28:02am

I can't answer your questions as I have never tried staged injection.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

| Home > A-Series EFI / Injection > Staged Injection | |||||||

|

|||||||

| Page: |