| Page: |

| Home > General Chat > thrust washer failures due to clutch pressure. | |||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

11th Jan, 2008 at 08:33:06pm

I was thinking about this today at work,

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

6965 Posts Member #: 507 Fastest A Series Mini in the World leeds/wakefield. |

11th Jan, 2008 at 09:00:34pm

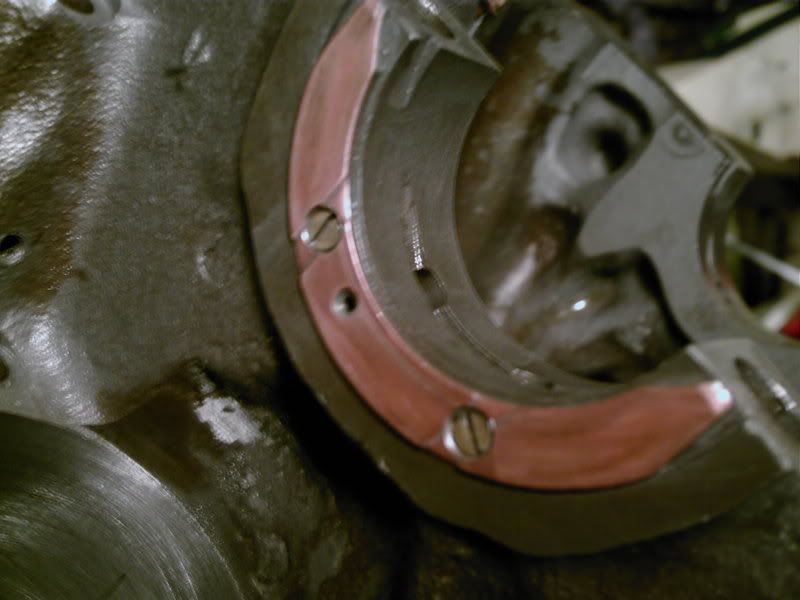

http://s24.photobucket.com/albums/c2/carl1...lfedthrusts.jpg

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

11th Jan, 2008 at 09:04:29pm

LOL!

Edited by Joe C on 11th Jan, 2008. On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

11th Jan, 2008 at 09:21:20pm

It was in the DON all last year. Thrust doesn't look too bad does it.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

1913 Posts Member #: 1392 Pointless Post Whore Liverpool, North west |

11th Jan, 2008 at 09:26:48pm

What a smart idea.

Back once again like a renegade master |

||||||

3756 Posts Member #: 1709 I like granny porn. LONDONSHIRE |

12th Jan, 2008 at 12:35:54am

cheers carl,think il be doing this on my engine at some point.... On 2nd Oct, 2009 Vegard said:

On 1st Oct, 2009 Jimster said:

I bet my first wank came quicker than your first mini turbo These new modern turbos with their quick spool up time, would make the competition harder. On 15th Aug, 2011 robert said:

phew!!! thank you brett for smashing in my back doors .( not something i imagined writing... EVER) |

||||||

9812 Posts Member #: 332 Resident Cylinder Head Modifier Mitsi Evo 7, 911, Cossie. & all the chavs ...... won no problem |

12th Jan, 2008 at 10:30:12am

what size hole is that tom ?

|

||||||

6965 Posts Member #: 507 Fastest A Series Mini in the World leeds/wakefield. |

12th Jan, 2008 at 11:20:32am

On 12th Jan, 2008 BENROSS said:

what size hole is that tom ? looks a tad large looks like a cure there for the wrong reason i think this will be widley adopted across the board now! you can't , ive just applied for a patent on the idea, seing as no one has thought of it before on the A series, . lol. lets call it £30.00 levy per install and i'll let you all use the idea,lol |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

12th Jan, 2008 at 11:27:16am

I'm interested to know why you used the screws.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

715 Posts Member #: 1381 Post Whore Doncaster, South Yorkshire |

12th Jan, 2008 at 11:34:02am

Paul, if you look at the ends of the washer you will see why.

|

||||||

7765 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

12th Jan, 2008 at 11:37:48am

On 12th Jan, 2008 danboy said:

Paul, if you look at the ends of the washer you will see why. Regards Dave No I don't.... On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

6965 Posts Member #: 507 Fastest A Series Mini in the World leeds/wakefield. |

12th Jan, 2008 at 11:39:14am

On 12th Jan, 2008 danboy said:

Paul, if you look at the ends of the washer you will see why. Regards Dave go on then dave tell me why i fixed them in place, see if your right,lol. carl |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

12th Jan, 2008 at 01:18:18pm

Well, Interesting stuff!!

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

12th Jan, 2008 at 01:34:01pm

Was it because the top half is self locating instead? Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

715 Posts Member #: 1381 Post Whore Doncaster, South Yorkshire |

12th Jan, 2008 at 03:02:52pm

Had to nip out to buy a guitar for the sprog.

|

||||||

7765 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

12th Jan, 2008 at 04:05:33pm

1: Makes perfect sense.

On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

|

715 Posts Member #: 1381 Post Whore Doncaster, South Yorkshire |

12th Jan, 2008 at 04:48:57pm

Edited by danboy on 12th Jan, 2008. |

||||||

6965 Posts Member #: 507 Fastest A Series Mini in the World leeds/wakefield. |

12th Jan, 2008 at 06:57:10pm

its to hold it back in place as mini 13 and danboy say, prevents oil pressuse pushing the thrusts against the crank,

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

12th Jan, 2008 at 07:11:57pm

As long as its not a meat lolipop. On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

4360 Posts Member #: 1459 En-suite user Braintree, Essex |

12th Jan, 2008 at 07:22:55pm

What a simple little solution. Quite impressed. On 19th Jan, 2010 wil_h said:

I would start the furthest place from the finish. On 24th Mar, 2012 apbellamy said:

I feel all special knowing that I've given your mum my wood. Been neglecting Turbo'd 'A' series.............. |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

12th Jan, 2008 at 07:37:41pm

is yours still in bits Jason? On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

4360 Posts Member #: 1459 En-suite user Braintree, Essex |

12th Jan, 2008 at 08:38:32pm

Yep Joe. You thinking what I'm thinking??????????? On 19th Jan, 2010 wil_h said:

I would start the furthest place from the finish. On 24th Mar, 2012 apbellamy said:

I feel all special knowing that I've given your mum my wood. Been neglecting Turbo'd 'A' series.............. |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

12th Jan, 2008 at 08:39:54pm

of course!! On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

12th Jan, 2008 at 08:40:39pm

Old news Edited by Sprocket on 12th Jan, 2008. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

4360 Posts Member #: 1459 En-suite user Braintree, Essex |

12th Jan, 2008 at 09:26:04pm

I like Carls method. Nice & simple. It does the job & it makes sense. Edited by Jason G on 12th Jan, 2008. On 19th Jan, 2010 wil_h said:

I would start the furthest place from the finish. On 24th Mar, 2012 apbellamy said:

I feel all special knowing that I've given your mum my wood. Been neglecting Turbo'd 'A' series.............. |

||||||

| Home > General Chat > thrust washer failures due to clutch pressure. | |||||||

|

|||||||

| Page: |