| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

2nd Feb, 2012 at 11:38:17pm

On 31st Jan, 2012 wolfie said:

Difficulty rating 1-easy 2-medium 3-hard 4-chuck norris 5-mattys gearbox build you missed one.... 1-easy 2-medium 3-hard 4-chuck norris 5-asian 6-mattys gearbox build no idea about gearboxes but it looks impressive; and expensive! |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

4th Feb, 2012 at 04:57:48pm

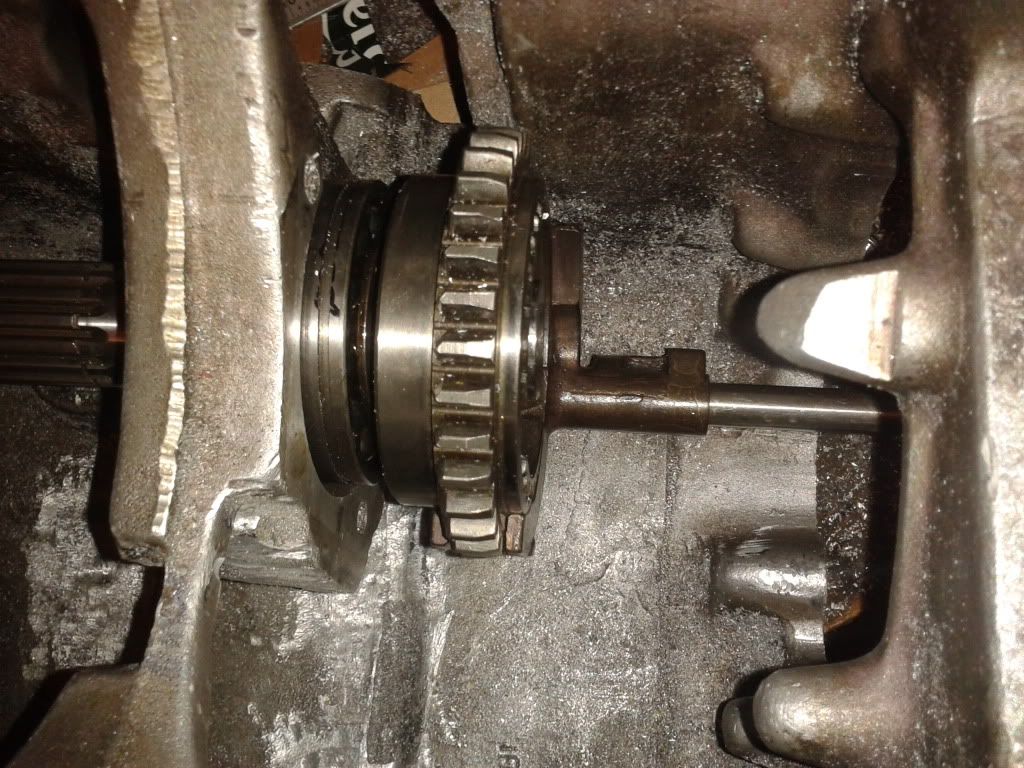

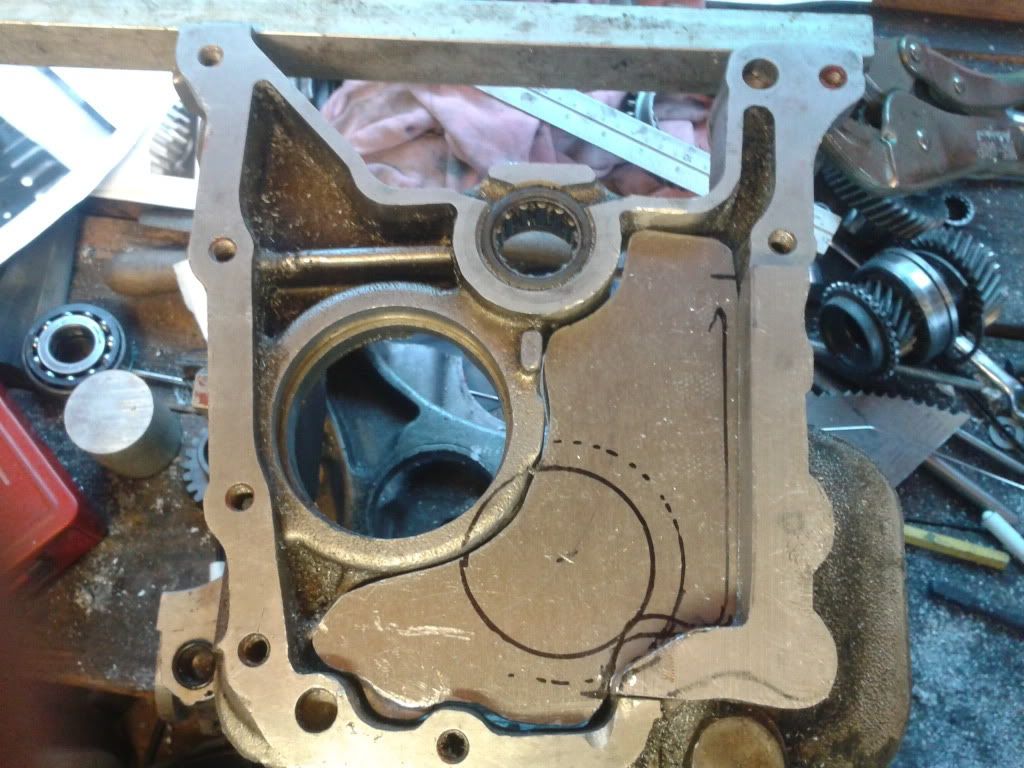

The final piece of the puzzle is nearly done ready to be welded into place, just some trimming to do now. The markings on the end case are where the new gear will be... the bearings are BLOODY close though! Too close for my liking, so im going to look for something more compact than 47mm OD on the bearing, something around 40mm would be good!

Edited by matty on 4th Feb, 2012. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

3673 Posts Member #: 9300 Post Whore Quarry Bonk |

4th Feb, 2012 at 05:01:50pm

Pretty sure it's just a press fit mate, I've seen stories of people levering them out to drain their oil o_O On 26th Jan, 2012 Tom Fenton said:

ring problems are down to wear or abuse but although annoying it isn't a show stopper On 5th Aug, 2014 madmk1 said:

Shit the bed! I had snapped the end of my shaft off!! 17.213 @ 71mph, 64bhp n/a (Old Engine) |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

4th Feb, 2012 at 05:05:17pm

What do you mean by spindle? The bit that they sit on with a nut on the top? That bashes out. The rest of the mechanism just slides out. On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

4th Feb, 2012 at 05:13:12pm

This bit. It looks like it just bashes out?

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

3673 Posts Member #: 9300 Post Whore Quarry Bonk |

4th Feb, 2012 at 05:28:59pm

Gi' it some ommer! On 26th Jan, 2012 Tom Fenton said:

ring problems are down to wear or abuse but although annoying it isn't a show stopper On 5th Aug, 2014 madmk1 said:

Shit the bed! I had snapped the end of my shaft off!! 17.213 @ 71mph, 64bhp n/a (Old Engine) |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

4th Feb, 2012 at 05:57:48pm

big hitting stick will see it out in no time On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

4th Feb, 2012 at 06:32:04pm

Excellent I'll save that job for a more socialable hour then. lol https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

6th Feb, 2012 at 09:47:59pm

I paid T&L engineering a visit today. Looks like they do some nice work there, but unfortunately they had the kind of "look down your nose" type of attitude towards me. Im guessing im just 8 cylinders short of the engines they generally work on. Edited by matty on 6th Feb, 2012. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

6th Feb, 2012 at 10:21:15pm

thers barely any case left Yes i moved to the darkside |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

6th Feb, 2012 at 11:33:46pm

Nope not much left, but im taking it to the welders tomorrow though.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

7th Feb, 2012 at 12:12:00am

dont think a door lock solenoid would be man enough personaly

Yes i moved to the darkside |

||||||

|

4314 Posts Member #: 700 Formerly British Open Classic The West Country |

7th Feb, 2012 at 12:37:41pm

Here's the machine shop I use:

Isambard Kingdom Brunel said:

Nothing is impossible if you are an Engineer |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

7th Feb, 2012 at 10:57:31pm

Ive seen some 60lbs force ones, seem to be mainly used in the hotrod scene. I agree the standard plastic ones look a bit feeble and difficult to mount!

On 7th Feb, 2012 Brett said:

dont think a door lock solenoid would be man enough personaly it wouldnt be hard to make your own imo, the starter solenoid ( pre-engaged type i assume ) is little more than a coil of wire Cheers Rob, I'll keep them in mind. We've done some measurements and the box will fit on the saddle of my mates lathe with an adaptor plate. I'd have to mill some flats on the underside of the box, but it looks like it might be the best option. On 7th Feb, 2012 Rob H said:

Here's the machine shop I use: http://www.turbominis.co.uk/forums/index.php?p=vt&tid=388876 Might be worth giving them a call & seeing if the can help. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6748 Posts Member #: 828 Post Whore uranus |

8th Feb, 2012 at 07:40:12am

goodoh , then you can use the end centre to keep it all true . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

580 Posts Member #: 9580 Post Whore Surrey |

8th Feb, 2012 at 08:11:23am

For soleniods have a look at albrightinternational.com then send me a PM. Might be able to help you out. |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

8th Feb, 2012 at 09:03:26pm

Shellspeed - Ive had a look on the site, but im finding it really difficult to narrow my search down. Is there any way to see some picutres of the solenoids? https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6748 Posts Member #: 828 Post Whore uranus |

9th Feb, 2012 at 10:44:54am

matt have a look at fag 's site ,there is a free bearing calc program called bearinx on there , may be of some use. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

9th Feb, 2012 at 10:21:52pm

Ive just had a look on fags site, but looks like you need to fill in some application form. Edited by matty on 9th Feb, 2012. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

9th Feb, 2012 at 10:36:36pm

go to your local starter/alternator place and grab a few solenoids, a solenoid off anythind pre-engaged (i.e. made in the last 20 years lol) and diesel is generally pretty meaty. other option could be a vacuum actuator? slower but less harsh turbo 16v k-series 11.9@118.9 :)

|

||||||

6748 Posts Member #: 828 Post Whore uranus |

10th Feb, 2012 at 08:24:39am

On 9th Feb, 2012 matty said:

Ive just had a look on fags site, but looks like you need to fill in some application form.

I had a look on SKF's site and they have a calculator but it doesn't work for needle rollers. lol I might give them a call when I get a chance though. send me schematics of the shafts and il enter it and send you a screen shot matt .i am a registered user on that site .but it only does sigle shaft calcs ,, but can narrow down the bearings choices . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

10th Feb, 2012 at 10:03:28pm

Robert, do you mean the dimensions or weights of the shafts? https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6748 Posts Member #: 828 Post Whore uranus |

11th Feb, 2012 at 08:32:54am

dimensions matt,oh ,and the od for all bearing positions ,it can then give a list of available sizes . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

14th Feb, 2012 at 04:52:21pm

As my gearbox is off to be welded I thought I'd crack on with the subframe.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

3756 Posts Member #: 1709 I like granny porn. LONDONSHIRE |

14th Feb, 2012 at 05:06:33pm

Nice work there matty!!

On 2nd Oct, 2009 Vegard said:

On 1st Oct, 2009 Jimster said:

I bet my first wank came quicker than your first mini turbo These new modern turbos with their quick spool up time, would make the competition harder. On 15th Aug, 2011 robert said:

phew!!! thank you brett for smashing in my back doors .( not something i imagined writing... EVER) |

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |

All I need to do is drill a hole in the new end plate and find a solenoid the right spec. Ive measured the selector movement and it 8mm, so if anyone knows where I can get a 12v push solenoid from (sealed type) that would save me hours more searching. Im also after a pinion to machine down if anyone has one spare?

All I need to do is drill a hole in the new end plate and find a solenoid the right spec. Ive measured the selector movement and it 8mm, so if anyone knows where I can get a 12v push solenoid from (sealed type) that would save me hours more searching. Im also after a pinion to machine down if anyone has one spare?