| Page: |

| Home > Show Us Yours! > Electric waterpump project | |||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

30th Oct, 2013 at 07:21:27pm

lol thats just fucking shoddy!

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

869 Posts Member #: 2443 Post Whore Cheshire |

30th Oct, 2013 at 07:36:32pm

That impellor is horrific on the leccy pump, surely there are versions with a little more engineering design for efficiency than that, from the picture it looks like it will be a shiny rotating restriction |

||||||

|

869 Posts Member #: 2443 Post Whore Cheshire |

30th Oct, 2013 at 07:43:18pm

I was picturing the high capacity pump impellors, there a really rough casted material which can't be good for efficiency, but whether it makes a notable difference is anyones guess! |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

31st Oct, 2013 at 07:42:21am

could you use the mini impeller on the electric pump? |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

31st Oct, 2013 at 07:50:48am

We use pump impellors not dissimilar to the lecy one pictured. They seem to work well. They work fairly well running backwards too, well, better than a closed face curved vane impellor does On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

31st Oct, 2013 at 10:04:08am

Right, I've found some more heat Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

224 Posts Member #: 9987 Senior Member Amsterdam |

31st Oct, 2013 at 10:10:44am

On 30th Oct, 2013 Paul S said:

Come on, you can always find something on the internet to prove an argument. Of course, if I'm wrong and the coolant heat load equals engine output, then a 20 USGpm pump is nowhere near big enough, yet they state that it can handle 250hp :) Paul, rest assured I'm not trying to prove an argument.....otherwise I had better kept quiet and have everyone think how clever I had been in selecting a 20Gpm pump for a 10Gpm flow requirement

If anything this great discussion has triggered me to dive much deeper into the subject, as such I wouldn't classify MIT-lectures on the subject containing SAE data etc. as something you can always find somewhere on the internet just to prove a point. I genuinely want to understand the dynamics, science is only as good as its ability to mimic reality.... ....talking about reality: What we do know through emperical evidence, is that the "Mercedes Bosch type chargecooler pumps" with a typical output of only around 5GPM is enough to satisfy the cooling needs of Bill Sollis' Miglia in the early 2000's. KAD has sold these pumps in the past, I think Simon-Madmk1 has been running one of these (?). Furthermore Matt has commented on running the Meziere 20Gpm pump at extended 110Mph runs (private roads of course), according to him his engine never ran cooler. This either points in the direction of all past literature on cooling heat load % has been wrong by a factor 250%-300%, which your sim software suggests....or the calculations are flawed. I will further look into this over the weekend as I don't have the time right now. In the meantime, I'm waiting for some spare cam drive belts to come over from the US*......so the project is unfortunately further halted by at least another week before I can perform some much awaited field testing. *Minispares has added the Dayco brand back to their portfolio, which has been out of stock for months now and won't become available again in a manner of weeks they told me. SHengineering are genuinely nice to deal with, unfortunately they carry only enough belts to satisfy their Miglia rebuild regime. |

||||||

|

224 Posts Member #: 9987 Senior Member Amsterdam |

31st Oct, 2013 at 10:23:11am

Paul, seems like our posts crossed.....thanks fo the heads up on the additional heat found! |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

31st Oct, 2013 at 11:00:09am

The fact that this is a small turbocharged engine does make a significant difference.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

248 Posts Member #: 7936 Senior Member DK-8450 Hammel. Denmark |

31st Oct, 2013 at 07:33:53pm

I do love this tread. The topic has interested me for some time.

If i have more toys than you when i die, I WIN |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

31st Oct, 2013 at 08:24:56pm

That's very interesting. I've calculated around 1.0 litre/second for 100hp and you measure about half that at 3000rpm. It's all pointing in the right direction.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

224 Posts Member #: 9987 Senior Member Amsterdam |

31st Oct, 2013 at 09:01:45pm

Turbotom, love your experiment!!! Thanks for sharing this data....

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

31st Oct, 2013 at 09:30:01pm

interesting although most of it goes over my head so i cant add much..

|

||||||

|

224 Posts Member #: 9987 Senior Member Amsterdam |

31st Oct, 2013 at 10:46:22pm

In addition to pump capacity and radiator efficiency, the coolant properties (specific heat index and viscosity) itself can also play an important role in cooling performance. For future reference I have taken the liberty of copying an earlier post on "waterless coolant" into this thread....

Edited by Evoderby on 1st Nov, 2013. |

||||||

|

248 Posts Member #: 7936 Senior Member DK-8450 Hammel. Denmark |

1st Nov, 2013 at 06:55:44am

My wife knows i do silly things. She has stoped wondering. Or maybe i stoped notishing On 31st Oct, 2013 Evoderby said:

periment!!! ....I can only imagine the look on my girlfriend's face if I were to perform an experiment like this  If i have more toys than you when i die, I WIN |

||||||

|

4018 Posts Member #: 1757 Back to Fucking Tool status Swindon |

1st Nov, 2013 at 07:24:04am

I belive this may turn into one of thoes custard moments. I going to wait to be suprised, good luck Drives

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

1st Nov, 2013 at 03:01:49pm

A 2-core radiator is really struggling with over 30kW of heat.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

690 Posts Member #: 1851 Post Whore Woolavington, Zummerzet |

2nd Nov, 2013 at 11:01:09am

I've just thought of something.

Metric is for people who can't do fractions. |

||||||

|

Forum Mod  5933 Posts Member #: 784 9 times Avon Park Class C winner Milton Keynes |

2nd Nov, 2013 at 11:17:28am

No Alex, my restrictor ring gives (more or less) the same restriction as an open thermostat I seriously doubt it! |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

2nd Nov, 2013 at 05:26:24pm

There seems to be a lot of personal experiences in this topic of of this pump works, this pump doesn't, this rad works, this rad doesn't.

Edited by turbodave16v on 2nd Nov, 2013. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

3rd Nov, 2013 at 02:35:11am

ive herd of casting that didnt form in the moulds and or never had inhibetor witch caused large amounts of nasty stuff that insulated the part from coolant |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

3rd Nov, 2013 at 01:09:04pm

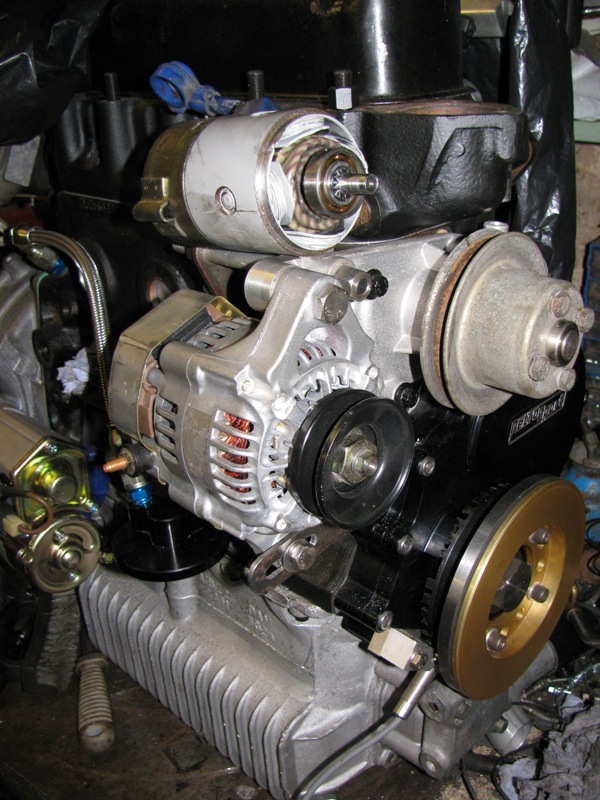

A month ago I had not thought of using an electric water pump. Now this thread has prompted me to do this:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

3rd Nov, 2013 at 02:59:28pm

LOL looks a bit heavy duty Paul, you going to drive the alternator off it too? On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

3rd Nov, 2013 at 04:09:23pm

The major problem with the a series pump design is that it doesn't have a housing around the impeller to help direct the flow of water.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

3rd Nov, 2013 at 04:51:13pm

On 3rd Nov, 2013 matty said:

The major problem with the a series pump design is that it doesn't have a housing around the impeller to help direct the flow of water. A pump will only ever be as good as the clearances set around the impeller. You only have to look at a turbo impeller and housing to see how important tight clearances are between the impeller and housing. The electric pump impeller may not be perfect in design, but matched with a decently designed housing it'll always be better then an a series pump. True, it lacks a pure volute. There is a notional volute formed by the pump casing and the hole in the block. As for clearances, I've just measured an old worn pump and the clearance is around 20 thou between the impeller and casing. There's not a lot of room for any re-circulation within the pump that would cause a drop in efficiency. Impeller design is fundamental to pump efficiency. The volute is just there to convert kinetic to potential energy. From someone who has makes a living from pumps and moving water, believe me when I say that the A-Series pump with the large cast impeller is far better than any radial vane pump. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

| Home > Show Us Yours! > Electric waterpump project | |||||||

|

|||||||

| Page: |