| Page: |

| Home > A-Series EFI / Injection > Tuning MegaSquirt for 998 NA | |||||||

|

857 Posts Member #: 1778 Post Whore Northants |

13th May, 2010 at 08:07:40am

You have to plug the LC-1 into a pc and use the config software. You also have to plug a mil eliminator (i think thats what they call it) into one end of the serial stream leed. |

||||||

|

857 Posts Member #: 1778 Post Whore Northants |

13th May, 2010 at 08:11:50am

Also make sure thats the only thing connected if your using more than one piece of innovate gear. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

13th May, 2010 at 08:47:37am

Yes, the Innovate setup software lets you set the voltage range to the AFR range.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

13th May, 2010 at 10:41:29am

On 13th May, 2010 Graham T said:

Rod, the major grid lines for time are 2 seconds apart. There are 14 spikes per 2 seconds. I'll do the maths a bit later, else I'll be late for work. Hmmm... I've blown the plot up a bit to read it better. It's 7-8 every 2 seconds (only count the upward going spike to give the frequency) so about 4Hz. Engine RPM went from 3100 to 3600 and because that's a relatively small change it's hard to see if the spike frequency rose with it. However, even if they were following, it's rubbish for my theory as that is a spike every 8 cycles (or 16 revolutions) and if the spikes were being caused directly by some engine event it would either be every 1/2 rev, once per rev or once per cycle. And if the spike frequency is not related to engine RPM, I can't think of any interference source that would generate 4Hz. Do they always (or even just often) seem to have a uniform frequency like on that one plot or is it just a red herring ??? EDIT - just out of interest, Paul, when you had one noisy, one fine, was it the inner or outer ??? I have a wild theory.... Edited by Rod S on 13th May, 2010. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

13th May, 2010 at 03:27:19pm

Rod, my spikes were on the outers. This was my problem:

Edited by Paul S on 13th May, 2010. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

13th May, 2010 at 04:53:55pm

A dribble??? ’77 Clubman build thread

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

13th May, 2010 at 05:04:03pm

On 13th May, 2010 Graham T said:

A dribble??? Just too much going to the inners and possibly causing a puddle. Then going into the cylinders in random amounts. Just a theory. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

14th May, 2010 at 08:08:01am

On 13th May, 2010 Rod S said:

Do they always (or even just often) seem to have a uniform frequency like on that one plot or is it just a red herring ??? Looking back over a few plots they are all fairly uniform once the revs settle at a constant. Any acceleration or decceleration and the spikes become less frequent but of higher amplitude. What's your wild theory rod?? ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

14th May, 2010 at 08:49:12am

On 14th May, 2010 Graham T said:

Looking back over a few plots they are all fairly uniform once the revs settle at a constant. Any acceleration or decceleration and the spikes become less frequent but of higher amplitude. If, when they are uniform, they are allways ~4Hz, then that is interesting..... On 14th May, 2010 Graham T said:

What's your wild theory rod?? Blown out of the water when Paul said his was on the outers and is fairly obviously electrical because of the proximity of the HT leads and tinfoil "fixing" it. What I was considering is that the sample rate, ie, frequency of the gas pulses, is different on the "inners" - I assume on your Normally Aspirated setup you are using an LCB of some sort so your "outer" sample is only from one of the outer cylinders (that is certainly how it is on our turbo setups using sample chambers) - whereas the testing I did on Normally Aspirated was just using a basic cast manifold with the LSUs in the steel downpipes (after the outers had been merged in the cast manifold). Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

15th May, 2010 at 09:44:37am

I'm using an LCB with the outer Lambda sensor on No1 Exhaust branch.

’77 Clubman build thread

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

15th May, 2010 at 10:07:55am

Jean con confirm, but i'm pretty sure that the alternating/simultaneous setting has no affect when using the sequential siamese option.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

15th May, 2010 at 11:19:01am

On 15th May, 2010 Graham T said:

I'm using an LCB with the outer Lambda sensor on No1 Exhaust branch. Just thinking about this and the fact you are using sample chambers: My inner lambda sensor is about 5" closer to the head than the outer. Could this be causing a problem - too close?? I'd thought because the engine is N/A heat would not be as much of a problem as it would be with the turbo setups?? I wouldn't have thought so, some people are running them right on the turbo elbow on turbo setups which is much hotter than Bosch recommend but without problems. Mind you, I don't think anyone is doing such detailed data plotting in those cases..... It is worth considering though as, irrespective of the exact position, the inner LSU must be much be hotter anyway because of twice the gas. I can't remember the difference Paul saw but I saw 150 - 200 C higher on the thermocouple I have on the centre branch compared to the (single) outer and that was without any load. If you think it's worth persuing further, the Innovate manual shows how to make a heat sink from a small piece of copper plate to drop the temperature without having to re-weld the boss. That's if you can get your hand down there to fit it....... Schrödinger's cat - so which one am I ??? |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

15th May, 2010 at 03:40:20pm

As Paul says, the alternating/simultaneous setting has no effect other than changing the req fuel value since there is only one valid injection sequencing.

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

27th May, 2010 at 01:38:25pm

On 15th May, 2010 Paul S said:

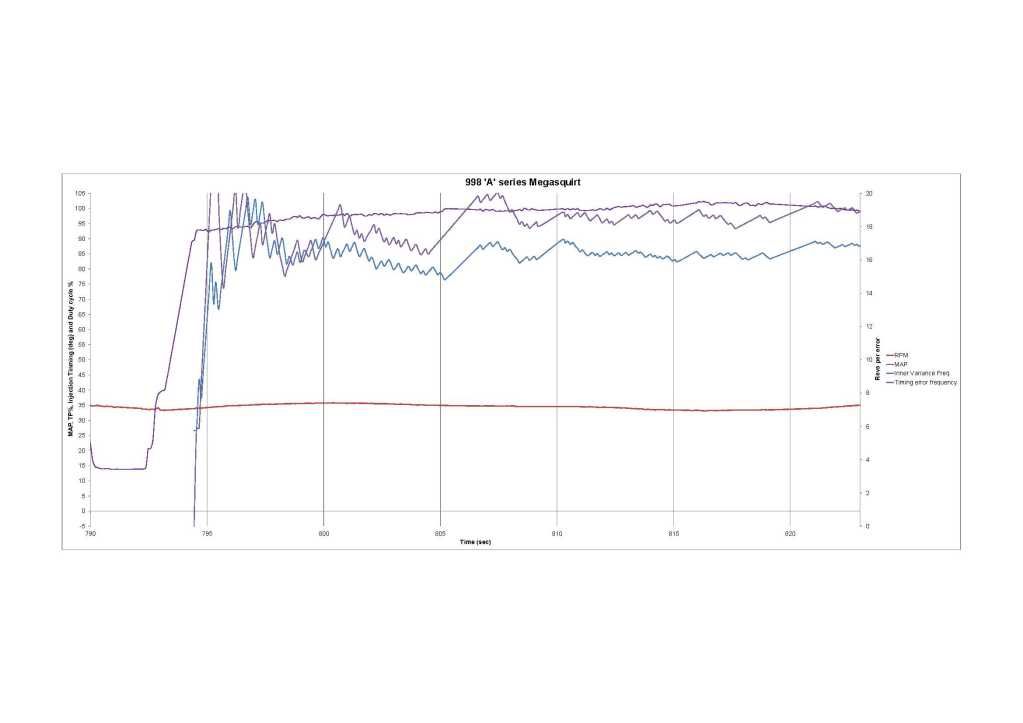

... I think that you basically are putting too much fuel into the engine. Just do a simple test by reducing REQ_FUEL by around 10%. My guess is that you will see the inner cylinders getting less fuel and a more stable signal. I have done trials with changing req_fuel and by reducing 10% which sent the inner AFR to over 20. At 5% reduction the inner AFR was on the readable scale, but still as Spikey. I have also checked out both LC-1's and they are both set: 2-5v representing 8:1 to 20:1 What I did find when I was tidying up the wiring after the Lambda sensor reversal was that there is still a fault in the crank sensor signal. I must have moved the signal wire because I could get no signal afterwards. I spent ages trying to get it to run before I "wiggled" the VR sensor which put right what ever was wrong. This prompted me to look at the timing err% field, which shows alot of variation. Playing with the figures in Excel I managed to produce the below. Taking a fairly level RPM base over 30 seconds I have an average of both AFR2 variations and timing err% variations. (Ignoring -ve figures) It may not be accurate because I had to filter variations on both AFR2 and timing err%. Using AFR1 variations as a base (anything below 0.4 considered ok) and timing err% below 0.3 as ok (tickover with no spikes).

So, it looks like the timing errors could be causing the spikes on the inners. In setting up the injection timing, If I advance injection timing I see the inners become lean and if I retard the timing the Inners go rich, but the outers stay fairly constant. So, what I am seeing between the inner AFR trace and the timing error % trace seems to reflect this. The crank sensor is the longer ford VR sensor, which is VERY close to the subframe and remembering Roberts post earlier in this thread: On 12th May, 2010 robert said:

from what i can see ,the spikes are greater when on full load ,that may suggest a emf from the ht leads/plugs ,do you have good suppressed leads ? i find the spiral wound stainless ones very good . I looked at the clearance: I think, but cannot be sure, that the sensor is hitting the subframe as the engine tilts forward underload, or atleast touching so it is vibrating, moving the sensor enough to vary the timing. It would be interesting to se the timing err% trace off another vehicle to see what sort of variation is "normal". Also, Paul, what VR sensor are you using on your setup? I only ask because I wonder whether the different model of sensor would make a difference to the MS pot adjustments needed to sync the signal? I do not need to change the setting to swap between car and Jimstim, where I know from emails with Rod he does. Just a thought... ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

27th May, 2010 at 02:24:03pm

Interesting....

Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

27th May, 2010 at 02:27:23pm

I've never looked at the timing_err% values before, but here is a log I took at the weekend:

Edited by Paul S on 27th May, 2010. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

27th May, 2010 at 02:32:41pm

I wonder if this is now showing the variations that Jean has allways said would come from using a timing signal from the "wrong" side of the damper pulley. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

27th May, 2010 at 02:33:54pm

On 27th May, 2010 Graham T said:

In setting up the injection timing, If I advance injection timing I see the inners become lean and if I retard the timing the Inners go rich, but the outers stay fairly constant. So, what I am seeing between the inner AFR trace and the timing error % trace seems to reflect this. I would have expected the opposite to that. Also any leaning of the inners should be reflected by a richening of the outers. Assuming that you are using a single VE table. Bearing in mind that you have a 180 degree window to get the fuel into the outer cylinders and 540 degrees to go into the inner cylinders. On my 998 Turbo at full chat, any movement away from the optimum will make the inners go richer. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

27th May, 2010 at 03:47:51pm

On 27th May, 2010 Graham T said:

I have done trials with changing req_fuel and by reducing 10% which sent the inner AFR to over 20. At 5% reduction the inner AFR was on the readable scale, but still as Spikey. This leads me to think that you have an AFR instrument error. If you reduce the total fuel by 10%, you would not see a halving of the fuel going to the inners. It just does not add up. If all the reduction came from the inners, then I would expect an increase in AFR from 10:1 to around 12:1. Do you have gauges on the widebands to check the TS/MLV readings? EDIT: Have you properly setup the widebands in TS. Select "Calibrate AFR..." You should see a screen like this:

If you have selected one off the standard Innovate options it may not match your LC-1 setup, so I would suggest using the settings in the picture above. Edited by Paul S on 27th May, 2010. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

27th May, 2010 at 05:30:21pm

timing_err% is only related to ignition because the spark outputs are done in a bit-bang mode, i.e., the outputs are set (on or off) by the code upon servicing the timer interrupt.

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

27th May, 2010 at 08:07:54pm

On 27th May, 2010 Rod S said:

Interesting.... I would have thought that the sensor moving - assuming it's just moving in and out towards the wheel so changing the gap rather than moving around it's circumference) would have minimal effect on timing. With the gap, as far as I'm aware, it either works or doesn't.... Sorry, that's not much help yet, may have mine running in a few days to compare (but more setbacks today.....) My thought here was that if there was any vibration/ contact with the subframe, the sensor bracket would flex, moving the sensor up and down, rather than in and out, hence changing the timing. But, Jeans post puts pay to that idea. On 27th May, 2010 jbelanger said:

timing_err% is only related to ignition because the spark outputs are done in a bit-bang mode, i.e., the outputs are set (on or off) by the code upon servicing the timer interrupt. For injection, this is different since the pins used are actually turned on and off by the hardware timers so the latency for servicing the interrupt has no impact on timing or pulse width. I don't know if the technical information is of any use to anyone but this is just to say that this parameter (timing_err%) should be meaningless in this case. The apparent correlation is just a coincidence or due to unrelated effects. Also, the injection window should be large enough that a small timing variation should have very little, if any, impact on AFR unless the injection is not actually done in the window. Jean ---- On 27th May, 2010 Paul S said:

... The timing error is higher during hard acceleration. You can see it is more settled at each end of the above trace. Values range from +6 to -9.5. What range of values are you seeing? ... I'm generally getting around +5.5 to -4.2. But the revs are max'd out at around 4,300 usually (if that makes a difference). ---- On 27th May, 2010 Paul S said:

On 27th May, 2010 Graham T said:

In setting up the injection timing, If I advance injection timing I see the inners become lean and if I retard the timing the Inners go rich, but the outers stay fairly constant. So, what I am seeing between the inner AFR trace and the timing error % trace seems to reflect this. I would have expected the opposite to that. Also any leaning of the inners should be reflected by a richening of the outers. Assuming that you are using a single VE table. Bearing in mind that you have a 180 degree window to get the fuel into the outer cylinders and 540 degrees to go into the inner cylinders. On my 998 Turbo at full chat, any movement away from the optimum will make the inners go richer. I'm not using a single VE table, although I have them set the same. No reason for the dual tables, only fear of breaking something if I changed to a single VE table. There is a richening of the outers when the inners go lean, but it would appear, not by anything like the same degree. I know you will shudder now, but I am still using dual injection timing tables. The reason for this is because no matter what angles I set with single table I have never been able to get the afrs closer than 3 apart, tickover being the worst affected. Most of the successful (at least they looked successful) trials I have had are by changing one table OR the other. I found that by advancing inj table 1 to a range of between 20 - 40 deg (tickover cells at 0), I can get the AFR's almost matching ( barring the spikes). Inj table 2 was left at 0 for the most part, barring tickover cells, which I have them set at -74 to -45. Thats the plot you see in my post of 2 April. I spent a month try single inj timing, but got no where. Also I have good results from leaving Inj table 1 at 0 throughout and a range of -21 to 1 on inj table 2. Not posted any plots of that because I've be concetrating on the spiking issue... I've alway wonder why this is the case because I would have expected to have had to retard the inj timing for the outer to get an AFR balance. Being as the inner injection window overlaps the outer injection window. BAsic understanding: inj table 1 is the outer cylinders. +ve inj timing figures activate the injector earlier in the cycle, -ve figures later??? ---- On 27th May, 2010 Paul S said:

... This leads me to think that you have an AFR instrument error. Perhaps not instrument error, more likely operator error. I remember doing something with this, but I cannot confirm because each time I open the wizard I get narrowband in the selection window, whether I burn the changes to the megasquirt or not. First job for the morning. On 27th May, 2010 jbelanger said:

...And you mention that the LC-1s are set to 2-5v representing 8:1 to 20:1 . This is an unusual setup and not one of the standards already defined (AFAIK) in TS so unless you specifically did the correct calibration, you have a wrong calibration. The default LC-1 range is 0-5V corresponding to 0.5 to 1.523 Lambda (7.35-22.39 AFR @ 14.7 for 1.0 Lambda) and the other commonly used range is 0-5v corresponding to 10-20 AFR. So the first thing to do is to check the calibration to make sure it matches between what the Innovate software says and what you set in TS. Then make sure that you have a stable tach trigger: you can use the sync error logger to see if you get any sync error. You may also want to switch your LC-1s from one ECU input to the other to see if the bad signal follows the LC-1 or the ECU input. Jean I would not have made changes so I will check this and change as needed. I took one of the LC-1's off our turbo mini, and that was played with a long time back. Who knows what I did back then. Certainly the new one I have not changed. I'll check it out. I have changed controllers on sensors and ecu inputs, and changed controller and sensors on exhaust branches. The spikes follow the inner cylinders at all times. All jobs for tommorrow. Thanks all for your help. ’77 Clubman build thread

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

28th May, 2010 at 02:35:14pm

Well, I would start by downloading the latest firmware to the old LC-1. This is avalable on the Innovate website.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

28th May, 2010 at 07:59:06pm

I checked the settings again today on the LC-1's and I got a strange afr to voltage in the input fields of of the old LC-1 of 1v = 1458 AFR.

’77 Clubman build thread

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

28th May, 2010 at 08:30:44pm

struggling to keep pace with where you are with these spikes gents, but thought i may throw this in.. a while back in the development of the msns-e codebase a few of us experienced random VE spikes every xx seconds (25 i think) after a code revision, turned out to be some counter in the code, which was refreshed on 10th second intervals and when it rolled over from 255 to 0 it messed up the acceleration injection, but only for those of us with certain settings enabled.

Edited by evolotion on 28th May, 2010. turbo 16v k-series 11.9@118.9 :)

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

28th May, 2010 at 09:01:37pm

Graham, remember to carry out re-calibration of the widebands in tuner studio. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

| Home > A-Series EFI / Injection > Tuning MegaSquirt for 998 NA | |||||||

|

|||||||

| Page: |