| Page: |

| Home > Show Us Yours! > Short Stroke - Project - Dyno-tastic | |||||||

324 Posts Member #: 9441 Senior Member South Devon |

7th Jan, 2017 at 12:02:09am

A short stroke crank won't flex as much as a standard or long stroke crank so won't put as much strain on the centre main.

|

||||||

243 Posts Member #: 1261 Senior Member Droitwich |

7th Jan, 2017 at 07:54:44am

Belts and braces tho, relatively inexpensive mod for the reassurance surely. |

||||||

|

45 Posts Member #: 11153 Member |

7th Jan, 2017 at 09:37:32am

I have no experience with the sa crank, but on researching crank strength in general I am sure the sa crank is considered one of the strongest cranks for two reasons.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

7th Jan, 2017 at 01:22:32pm

I was thinking the same, but i suspect V also thinks that my charger will run out of puff before any super high RPM's are reached, but lets see :) I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

1750 Posts Member #: 10190 Post Whore belgium |

7th Jan, 2017 at 03:53:46pm

cant that be solved with a different size pulley? maybe less effectief in the low revs then but think the short stroke would make up for this? you can do anything if you set your mind to it...

|

||||||

7763 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

7th Jan, 2017 at 08:06:13pm

personally I don't fit straps on any engines. Why would milling a bunch of material of the centre main and adding some steel bar make things stronger? Steel caps yes, but a strap? Old gospel.

Edited by Vegard on 7th Jan, 2017. On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

7th Jan, 2017 at 11:04:42pm

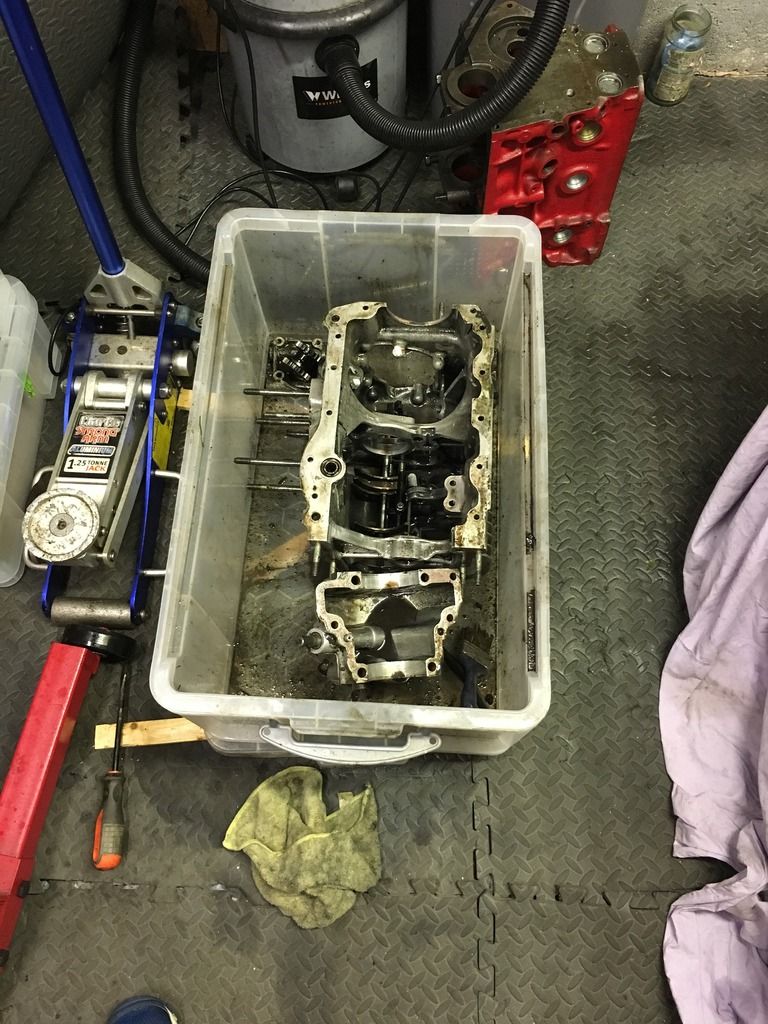

So I had a couple of hours in the garage this evening. I stripped down a spare gearbox casing that I had. I had driven this gearbox for a short period of time and it was very crunchy.

Edited by gr4h4m on 7th Jan, 2017. I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4625 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

7th Jan, 2017 at 11:36:54pm

Regarding the main strap. Why not fit some proper high tensile bolts and washers to the centre main cap ?

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

7th Jan, 2017 at 11:44:48pm

I must admit I have ordered the set of washers that V posted. I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

1849 Posts Member #: 672 The oversills police Oslo, Norway |

8th Jan, 2017 at 07:04:04am

On 7th Jan, 2017 Vegard said:

personally I don't fit straps on any engines. Why would milling a bunch of material of the centre main and adding some steel bar make things stronger? Steel caps yes, but a strap? Old gospel. Those who preach the gains of a strap say it's because the long stroke of the 1275 flexing of the crank. The SA crank doesn't flex. Ask Dave Wells of SH how many of his engines that uses main straps? Who's winning Miglias and FIA races? His engines. Just sayin'

When that is said, I ALWAYS fit these. https://www.ebay.co.uk/itm/291409493605 Well. You are wrong. SH never use steel caps, but he does use a strap, a very big one too, and work the original caps a bit to remove stress risers |

||||||

1849 Posts Member #: 672 The oversills police Oslo, Norway |

8th Jan, 2017 at 07:04:04am

On 7th Jan, 2017 Vegard said:

personally I don't fit straps on any engines. Why would milling a bunch of material of the centre main and adding some steel bar make things stronger? Steel caps yes, but a strap? Old gospel. Those who preach the gains of a strap say it's because the long stroke of the 1275 flexing of the crank. The SA crank doesn't flex. Ask Dave Wells of SH how many of his engines that uses main straps? Who's winning Miglias and FIA races? His engines. Just sayin'

When that is said, I ALWAYS fit these. https://www.ebay.co.uk/itm/291409493605 Well. You are wrong. SH never use steel caps, but he does use a strap, a very big one too, and work the original caps a bit to remove stress risers |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

21st Jan, 2017 at 10:19:28pm

Well, things move on, I have the block back from the Headshop Uk in Warrington. The block has been bored to +40, new cam bearings, decked, 11 stud and main cap machined for a strap. All looks nice.

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4625 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

21st Jan, 2017 at 10:30:37pm

Glad to see it coming together mate. You going to Bingley ?

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

21st Jan, 2017 at 10:33:49pm

yep, shotgun with Colin. See you there? I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4625 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

21st Jan, 2017 at 10:59:27pm

Yes mate.

|

||||||

2094 Posts Member #: 9894 Post Whore Dorking |

22nd Jan, 2017 at 08:28:36pm

Very nice.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

22nd Jan, 2017 at 09:05:32pm

Got a bench top parts cleaner today, does a great job with the small parts! I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

24th Jan, 2017 at 10:55:05am

ok as an update. I have been cleaning, cleaning, and more cleaning the gearbox case.

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

24th Jan, 2017 at 09:48:16pm

Oh cock....

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

|

703 Posts Member #: 105 1st to provide proof of a running Bimmy Conversion! Brisbane ,Australia |

3rd Feb, 2017 at 10:20:44pm

Hey Graham, first-up--> great choice of eng design BTW www.miniman.com.au

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

3rd Feb, 2017 at 11:26:14pm

Hi Matt I did order it from Aus. So it must be one of yours.

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

5th Feb, 2017 at 06:38:00pm

Has anyone had issues with the retaining plate fitting into a new minispares layshaft? I would have thought it would be an easy fit as it's will have worn a little?

Edited by gr4h4m on 5th Feb, 2017. I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

6th Feb, 2017 at 11:29:16pm

So I have got to the dry build and have a big issue, the Rods I have been sent have the wrong BE size. They are for the CooperS from what I can tell, I think the trader had an issue with his original order. I have emailed him to see if he can help., but with the issue I had with the wrong piston fitment and having to get the pistons machined I should have checked the BE but the crank was at the first machine shop! Fingers crossed.

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

243 Posts Member #: 1261 Senior Member Droitwich |

7th Feb, 2017 at 07:34:00am

Shouldnt be to hard to source std rods tho, at least you got the ones worth more so by the time you've swapped them you should be in profit.

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

26th Feb, 2017 at 10:46:12pm

So I have had a few setbacks, stuff not fitting, wrong stuff being sent etc..

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

| Home > Show Us Yours! > Short Stroke - Project - Dyno-tastic | |||||||

|

|||||||

| Page: |

it`s one we have been procuring & sourcing parts & designing for a long time now, i`ll get to finish it one day

it`s one we have been procuring & sourcing parts & designing for a long time now, i`ll get to finish it one day