| Page: |

| Home > Technical Chat > Fitting dual wideband 02 sensors | |||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

13th Oct, 2014 at 07:32:47pm

Understood I have flow but I would be very surprised at 70mm for so little heat in a dead leg.

Schrödinger's cat - so which one am I ??? |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

13th Oct, 2014 at 08:32:43pm

Good info. I think I'll be ordering a pair of LSU4.9's...... Sorry I can't input on this topic as I've got a full compliment of ports, but I already have a wideband pre and post turbo with a Delta P (DPF) sensor. It'll be a bit yet before I have any data for comparison though. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

13th Oct, 2014 at 08:53:22pm

Just in case you didn't know, you have to have a controller that explicitly supports the 4.9. It's not a simple plug in replacement for the 4.2. That requires different hardware and different code in the controller. |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

13th Oct, 2014 at 09:09:05pm

Cough...............

On 13th Oct, 2014 jbelanger said:

Just in case you didn't know, you have to have a controller that explicitly supports the 4.9. It's not a simple plug in replacement for the 4.2. That requires different hardware and different code in the controller. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

13th Oct, 2014 at 09:31:42pm

On 13th Oct, 2014 Sprocket said:

Cough............... ? |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

13th Oct, 2014 at 09:37:21pm

When welding stainless, I've always read that you need slightly less current as it doesn't wick the heat away, and when you weld Aluminium you can struggle to get enough heat into it because it conducts away so easily. To put some numbers on it, see bellow, but I can't remember what on earth the units mean.

Edited by PhilR on 18th Oct, 2014. |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

13th Oct, 2014 at 09:48:42pm

http://industrial.boschautoparts.com/Techn..._0281002772.pdf

Edited by Sprocket on 13th Oct, 2014. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

13th Oct, 2014 at 10:00:27pm

I think you'd be much better off with 2 absolute pressure sensors. Having a differential pressure gives you no indication if the post turbo sensor is seeing any significant pressure or not.

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

13th Oct, 2014 at 10:13:48pm

I was interested in something like that for a completely unrelated project - to continually check the balance of a pair of carbs. I don't actually think that one would work now that I've seen the specs, but good to know. Edited by PhilR on 13th Oct, 2014. |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

14th Oct, 2014 at 01:01:36am

On 13th Oct, 2014 jbelanger said:

Just in case you didn't know, you have to have a controller that explicitly supports the 4.9. It's not a simple plug in replacement for the 4.2. That requires different hardware and different code in the controller. Yes, I realised that and added an edit to one of my posts part way down the second page (I added the edit a couple of hours after the original post so it may have been missed). It's interesting that on the SLC Free design it's just one extra resistor and on my old TechEdges it's swap a jumper (I haven't yet looked at the schematic to see what that jumper does) but annoying that on my SLC OEMs it specifically states 4.2 only. I've posted a couple of questions on Alan's forums but previous experience tells me not to hold my breath.... Schrödinger's cat - so which one am I ??? |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

14th Oct, 2014 at 07:58:34am

On 14th Oct, 2014 Rod S said:

On 13th Oct, 2014 jbelanger said:

Just in case you didn't know, you have to have a controller that explicitly supports the 4.9. It's not a simple plug in replacement for the 4.2. That requires different hardware and different code in the controller. Yes, I realised that and added an edit to one of my posts part way down the second page (I added the edit a couple of hours after the original post so it may have been missed). It's interesting that on the SLC Free design it's just one extra resistor and on my old TechEdges it's swap a jumper (I haven't yet looked at the schematic to see what that jumper does) but annoying that on my SLC OEMs it specifically states 4.2 only. I've posted a couple of questions on Alan's forums but previous experience tells me not to hold my breath.... I understand the differencies. I've been waiting for the last 6 months for firmware since the subject first came up. I even have the smaller connectors here ready to wire up. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

14th Oct, 2014 at 08:16:12am

I've just gone back to my old TechEdge units and it is both change jumpers and load alternative firmware with them - easy because they provide the firmware on their website and from what I remember when I first built them and they recommended an immediate upgrade it was just as easy as, say, updating the firmware on an MS2/3.

Edited by Rod S on 14th Oct, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

14th Oct, 2014 at 09:19:28am

I've just ordered two of the SCL Free with 4.9 sensors. I had a quick look on their forum and there was one post that seemed to suggest the firmware was different between 4.2 to 4.9. I couldn't really find out much other info on them, but for the price, I'll be happy if they just work.

Edited by PhilR on 14th Oct, 2014. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

14th Oct, 2014 at 09:25:18am

On 13th Oct, 2014 PhilR said:

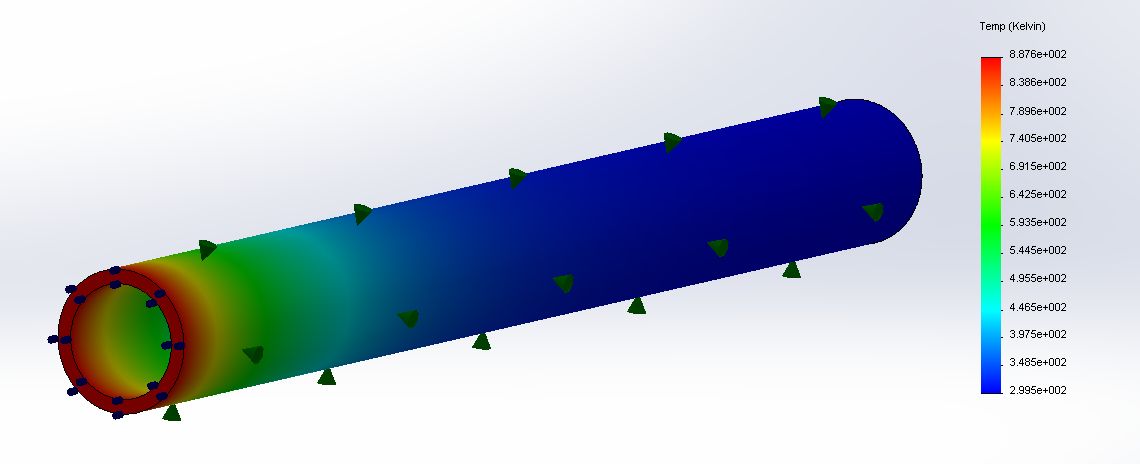

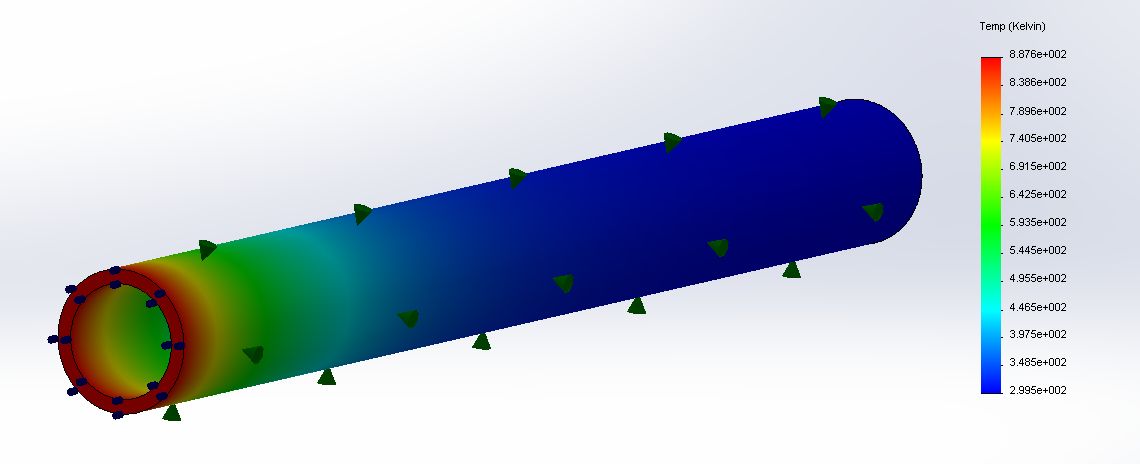

Quick experiment with stainless tubing...

This is 10mm stainless tubing that I've heated to 800-900 degrees C , 30mm from the left hand end, using Mapp gas. The camera goes mad for infra-red light so it's not actually white hot, but it's bright red. In a minute, the temperatures seemed stable and at 5 minutes of heating the temperatures were a steady 70 degrees over ambient at 70mm from the centre of the flame. The maximum working temperature of silicone tube is perhaps 250 C, so assuming an under bonnet temperature of 100 C and temperature change from conduction at 70 C , I think you could plumb a sensor in with a 70mm pipe welded directly to the exhaust. I agree:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

14th Oct, 2014 at 11:34:05am

On 14th Oct, 2014 PhilR said:

I've just ordered two of the SCL Free with 4.9 sensors. I had a quick look on their forum and there was one post that seemed to suggest the firmware was different between 4.2 to 4.9. I couldn't really find out much other info on them, but for the price, I'll be happy if they just work. Would be interesting to see if there have been any other changes. I saw pictures of another unit that had longer board spacers to clear the caps that were a problem on yours. It looked like screen pins were then raised up and not seated fully in their socket. I'll get a better idea when they turn up. I saw the photo with the longer spacers. I found a few other issues which I discused with Alan (by email) but he didn't consider them "significant" but said he would alter the next batch, not sure if he actually will/did as he didn't take my constructive criticism too well... If your PCBs arrive as v1.01 PM me and I'll give you my thoughts. Re. the longer spacers, it would be nice to think he also changed to extended pin headers (they are available as I've used them on an RPi project) but even with extended spacers (I added washers) and standard headers there is still adequate engagement. If you are going to swap the headers for an IDC connector and ribbon cable it won't be an issue anyway. On 14th Oct, 2014 Paul S said:

I agree:  You complain about me using electrickery and here you are, running a simulation rather than getting a blowtorch out

It does confirm lack of gas flow means sod all heat transfer along the tube, surprising to me at least. As promised, what a sample tube did to one of my TCs

The damage was during garage testing (minimal load) and before the tubes (hidden in the shadows) changed colour. It makes me wonder if the sample tubes could be made smaller as there is clearly quite a bit of flow down mine as both of you have shown with zero flow tests/simulations. With digital data from my SLC OEMs I have extremely fast reading variations on the new digitally driven LED displays, so fast it's hard to read the second decimal place so I doubt I'll compromise the readings using smaller tubes. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

14th Oct, 2014 at 12:18:03pm

On 14th Oct, 2014 Rod S said:

You complain about me using electrickery and here you are, running a simulation rather than getting a blowtorch out

It does confirm lack of gas flow means sod all heat transfer along the tube, surprising to me at least. Just 10 minutes on the CAD is a lot quicker than finding all the bits to repeat Phil's test

On 14th Oct, 2014 Rod S said:

It makes me wonder if the sample tubes could be made smaller as there is clearly quite a bit of flow down mine as both of you have shown with zero flow tests/simulations. With digital data from my SLC OEMs I have extremely fast reading variations on the new digitally driven LED displays, so fast it's hard to read the second decimal place so I doubt I'll compromise the readings using smaller tubes. How much smaller were you thinking? I can only find 4mm OD 2mmID on ebay, but that would be too small, or would it?. Distinct lack of 5mm stuff and fittings to suit. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

14th Oct, 2014 at 01:09:55pm

On sample chambers, do you use any other restriction? What if you used a shorter length of 6 or 10mm tube to keep the strength, and had a restrictor at the end of the tube.

Edited by PhilR on 14th Oct, 2014. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

14th Oct, 2014 at 01:40:39pm

On 14th Oct, 2014 PhilR said:

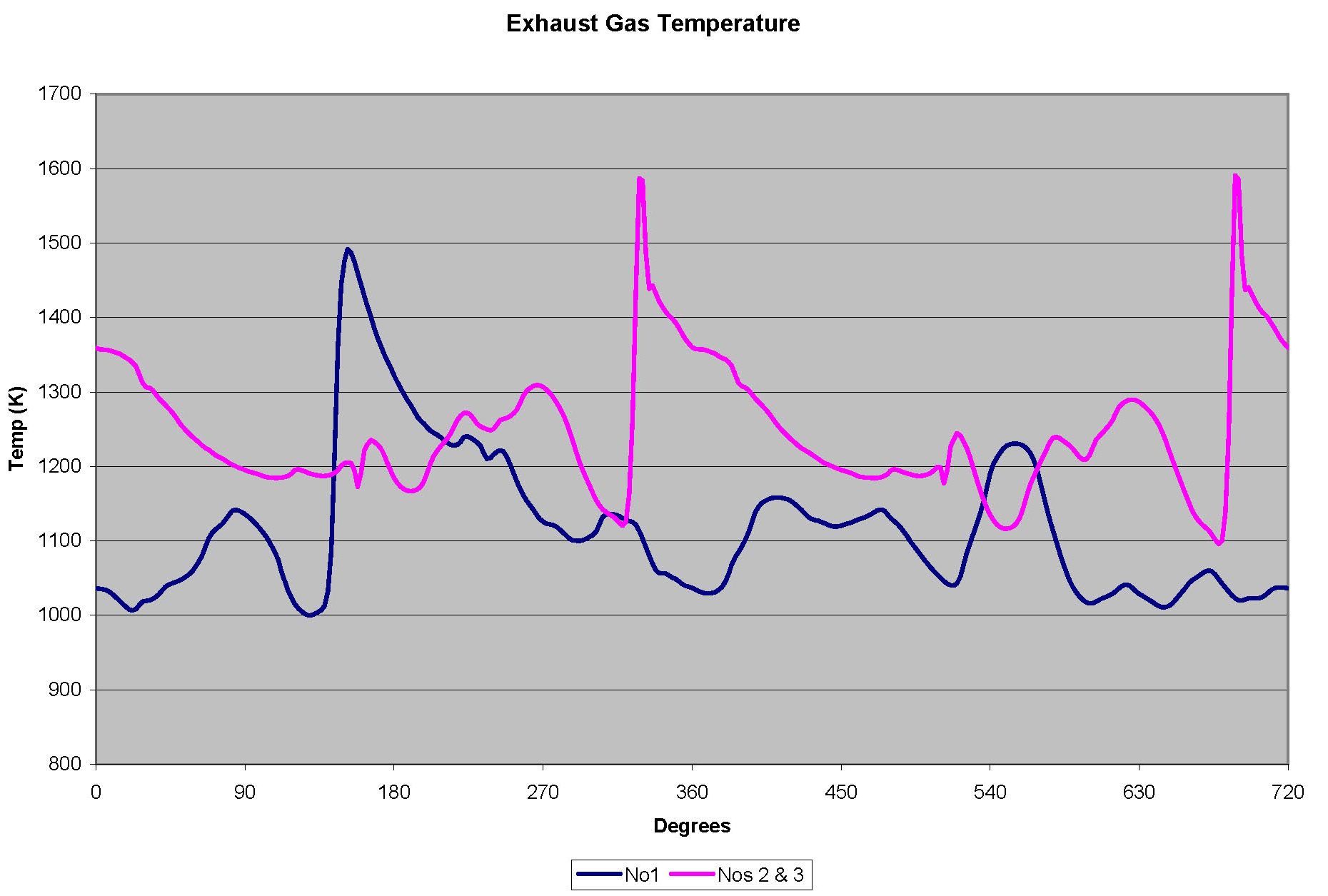

I've been thinking about how to make the o2 boss for the non sample tube version. I've seen some EGT logs that Paul posted in 2008, that showed temperatures around 700 C. Would you say these are typical temperatures? Do you remember how far into the exhaust flow the probes were positioned? Those logs were in NA mode. I didn't bother logging EGTs on the turbo engine once I realised that the inners were always going to run a lot hotter due to a higher cycle average. The thermocouples were inserted into the centre of the pipe. This is an output from the simulation of what I can expect from my new 998 at 0.8 bar boost:

EDIT: These are the EGTs at the head flange. Numbers above are further along the LCB style manifold. Cycle average on the inner cylinders is nearer 1000 Deg C. I will be logging EGT in the future, just to calibrate the simulations. Edited by Paul S on 14th Oct, 2014. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

14th Oct, 2014 at 05:18:49pm

To confirm, there is definitely a difference in the code in the SLC Free between the 4.2 and 4.9 versions. At a minimum, there are some different PID settings and a different temperature target. |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

14th Oct, 2014 at 05:47:31pm

On 14th Oct, 2014 jbelanger said:

To confirm, there is definitely a difference in the code in the SLC Free between the 4.2 and 4.9 versions. At a minimum, there are some different PID settings and a different temperature target. Yes, I guessed as much this morning that it is more than just a resistor change when I went through the TechEdge datasheets on the subject. It's a shame there is no label or marking of any sort on the microcontroller I have to say it's for 4.2 only. Someone might think from the instructions just to remove/replace a single resistor on the PCB. But we've been here before with the fiasco over the early SLC OEM addressing issues. I still think the 14point7 range are really good products but, although customer service may have improved, attention to detail hasn't. Just my thoughts and not trying to put anyone off, I use his stuff but with a bit of caution. Schrödinger's cat - so which one am I ??? |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

14th Oct, 2014 at 07:46:10pm

A simple sticker on the board that says "4.2 only" or "4.9 only" and a short notice about it somewhere would go a long way towards making it obvious that you have this limitation. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

14th Oct, 2014 at 09:14:19pm

On 14th Oct, 2014 Rod S said:

On 14th Oct, 2014 jbelanger said:

To confirm, there is definitely a difference in the code in the SLC Free between the 4.2 and 4.9 versions. At a minimum, there are some different PID settings and a different temperature target. Yes, I guessed as much this morning that it is more than just a resistor change when I went through the TechEdge datasheets on the subject. It's a shame there is no label or marking of any sort on the microcontroller I have to say it's for 4.2 only. Someone might think from the instructions just to remove/replace a single resistor on the PCB. But we've been here before with the fiasco over the early SLC OEM addressing issues. I still think the 14point7 range are really good products but, although customer service may have improved, attention to detail hasn't. Just my thoughts and not trying to put anyone off, I use his stuff but with a bit of caution. Is that not the difference between a large commercial company and a small one man band type, its not like you are paying the same money for the goods? It also sounds like he has some good USP's with the sensor calibration and heater output information? just view I love these small startups they normally have great prices and a couple of cool ideas however, as I get older I don't mind paying more for the "Apple" style customer care..... I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

|

8 Posts Member #: 10981 Junior Member |

15th Oct, 2014 at 02:24:18am

For SCL Free, there are different firmwares for 4.9 (B) and 4.2 ©. In the SLC Free manual it states "SLC Free B displays a sensor temperature range of 740C to 820C, SLC Free C displays a sensor temperature range of 670C to 828C"

|

||||||

6748 Posts Member #: 828 Post Whore uranus |

15th Oct, 2014 at 06:58:36am

something else that occured to me is does the combination of temp and pressure have an effect ?

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

15th Oct, 2014 at 08:47:46am

Good to see some input from an expert in the field.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

| Home > Technical Chat > Fitting dual wideband 02 sensors | |||||||

|

|||||||

| Page: |