| Page: |

| Home > MS Trials & Testing > MS3X MPi Trials | |||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

7th Mar, 2014 at 11:17:27am

On 7th Mar, 2014 Rod S said:

On 7th Mar, 2014 dan187 said:

Clearly either rover or myself put the cam in 360 (crank) degrees out. If you're using the standard MPI cam and pickup, the "mistake" was most likely over 60 years ago as the pickup runs through a slot cut in the old mechanical fuel pump lobe on the cam and I doubt they re-manufactured the cam to put that lobe at an ideal angle for the MEMS, more likely they just set the code/wiring to suit what was already there. Thanks Rod, yeah I was suggesting Rover did it for ease of manufacture (rather than a 1 off cock-up). |

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

7th Mar, 2014 at 11:22:29am

On 7th Mar, 2014 Paul S said:

Glad to see you're making progress. 10% extra fuel is all that was missing. The standard FPR must have been running at around 2.5 Barg. Thanks. Yeah, i'm sure i've read in a few places that's what some people have measured. A bit more fine tuning and then i'll also try some closed loop control to see how that copes. Should work well at low rpm if I have the pulse set nicely in the middle. I'll use it to help with warm up as the AFRs wander from each other as the walls etc warm. On a subjective note Paul, this setup feels nicer to run than the 1 long pulse. It also seems the wander less during warm up. I guess because if I have the timing right i'm in the middle of the valve lift not right at the start. so for small PW its more likely to go in the cylinder. What's you latest progress with MS? You mentioned you're running the 998 using the MPi maniold, presumably N/A. What was the reason for that? Edited by dan187 on 7th Mar, 2014. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

7th Mar, 2014 at 11:43:05am

The 998 with the MPi manifold is my middle lads car. The MPi manifold is a temporary measure to get the car on the road. It will be fitted with the T2 and manifold from the 998Ti. Also a new design 350mm runner inlet manifold.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

7th Mar, 2014 at 12:03:24pm

On 7th Mar, 2014 dan187 said:

On a subjective note Paul, this setup feels nicer to run than the 1 long pulse. It also seems the wander less during warm up. I guess because if I have the timing right i'm in the middle of the valve lift not right at the start. so for small PW its more likely to go in the cylinder. I think you have hit the nail on the head with the last words "so for small pulse widths it's more likely to go into the right cylinder". To do the individual pulses you really do need over-sized injectors AND get the timing exactly right for all load/RPM points. The single overlapping pulse, even though I've not tried it, has to be easier although the results may not be quite so good. Ironically, if you read back through all the Rover documentation of the MPI development, they apparently opted for a mixture of both, probably to keep the injectors small. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

7th Mar, 2014 at 12:15:27pm

The issue with the individual pulses was the short pulse widths at idle.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

27th Mar, 2014 at 11:16:29pm

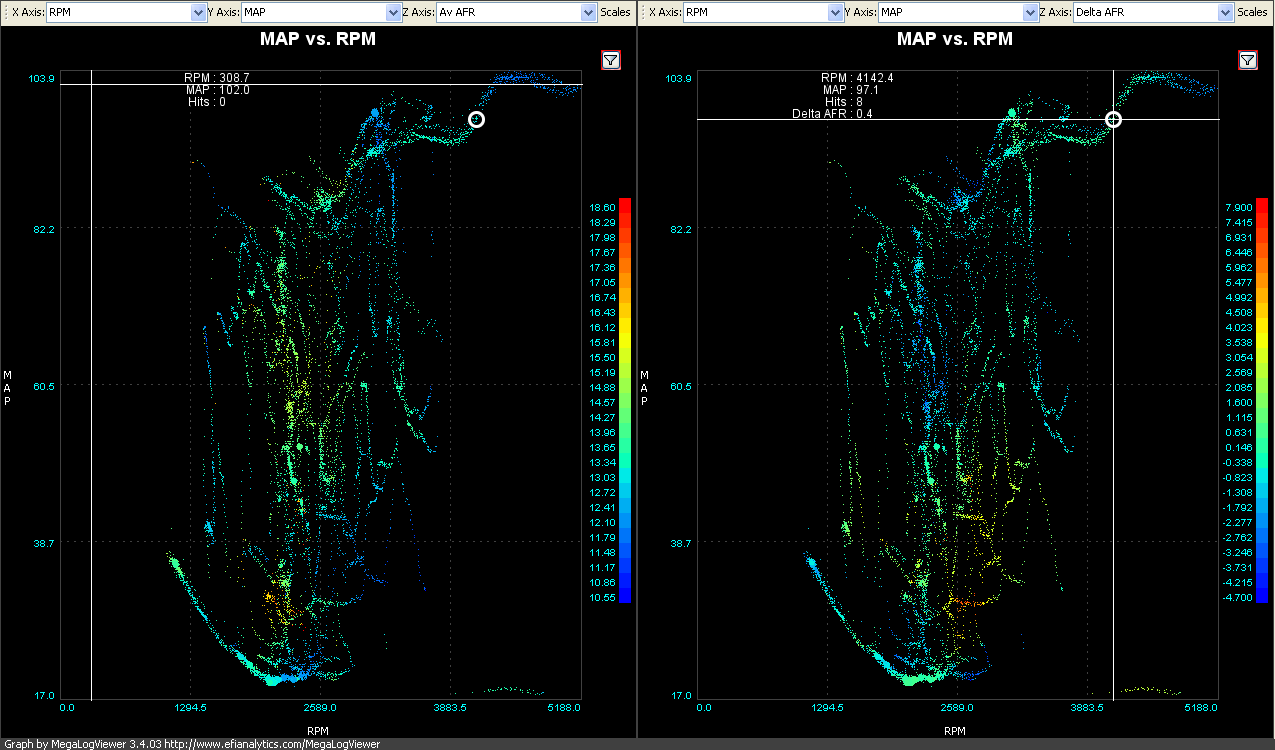

So I've been tuning the individual pulse system for the last couple of weeks. It drives a lot better than the overlapping pulse. I think the most noticeable thing is the throttle response is improved due to the shorter PWs required and the greater frequency of injection. It is much easier to tune too. I've been adjusting each injector with the trim tables. The biggest issue is the resolution of the tables. I could do with a couple more bins. On the whole though a much better drive. EGO correction seems to be doing a good job at correcting most errors. Image below shows the latest AFR results. left hand plot is the difference between the inners and outers and right hand is the error of outers from the AFR target table. You can see at high rpm full throttle i'm not able to get enough fuel into the outer without filling the inners with bucket loads of fuel. Hence why I need to crack on with the manifold. Hopefully get started next month on that.

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

28th Mar, 2014 at 12:52:25am

I know this won't help you but the MS2/Extra code should be noticeably better when using individual pulses since it has code dedicated specifically for it. I just want to point it out for anyone looking at this and thinking about doing the same.

Edited by jbelanger on 28th Mar, 2014. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

11th May, 2014 at 09:23:28am

On 7th Mar, 2014 dan187 said:

I didn't measure fuel pressure before but now it is about 3.3 bar (seems that is max that the MPi pump can provide). If your Mpi pump can only get as high as 3.3 barg, then it must be knackered. You may have pressure in the system at idle, but I doubt the flow is high enough to supply the injectors under heavy load. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

12th May, 2014 at 11:53:41am

On 11th May, 2014 Paul S said:

On 7th Mar, 2014 dan187 said:

I didn't measure fuel pressure before but now it is about 3.3 bar (seems that is max that the MPi pump can provide). If your Mpi pump can only get as high as 3.3 barg, then it must be knackered. You may have pressure in the system at idle, but I doubt the flow is high enough to supply the injectors under heavy load. Oh, that's an interesting idea. I'd assumed 3.3 was about right. Any ideas what the max should be? I'll do some googling |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

12th May, 2014 at 12:13:27pm

The fuel injection pumps are positive displacement, so you should be able to wind up the regulator to at least 5-6 bar before either the fuse blows or the pump fails.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

12th May, 2014 at 12:50:42pm

On 12th May, 2014 Paul S said:

The fuel injection pumps are positive displacement, so you should be able to wind up the regulator to at least 5-6 bar before either the fuse blows or the pump fails. If you can only get to 3.3 Bar, then the pump must be worn and flow is circulating within it and not building pressure at the regulator. I'm assuming that your statement about the max that the MPi pump can provide means that you have tried to wind it higher. Yeah it's this regulator: http://cgi.ebay.co.uk/ws/eBayISAPI.dll?Vie...ME:L  U:GB:3160 U:GB:3160

I tried winding it right in but it only increased from 3 to 3.3 bar I'm looking at this for a higher flow replacement: http://cgi.ebay.co.uk/ws/eBayISAPI.dll?Vie...atchlink:top:en |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

12th May, 2014 at 12:58:07pm

We've used the Walbro 255/Mpi conversion on the Mini 30.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

12th May, 2014 at 03:37:09pm

For what it's worth, on my old (now long gone) 16V K series Metro, the in-tank pump started to run erratically long before it should have failed.

Schrödinger's cat - so which one am I ??? |

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

20th May, 2014 at 08:24:10pm

Got the Walbro 255 fitted... Paul you're a fantastic man! Problem solved, turned up fuel pressure and got 5 bar before I was more than convinced it was working.

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

20th May, 2014 at 09:02:34pm

Most setups run at 3 Bar and this is the pressure used for measuring injector capacity in most cases. Some setups run 3.5 Bar but that's usually returnless setups.

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

20th May, 2014 at 09:16:44pm

Glad you got it sorted.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

21st May, 2014 at 11:35:26am

On 20th May, 2014 Paul S said:

Also 0.5 bar boost will add 0.5 bar to the pressure, not 50%, so no problem. Doh, oh yeah. Not sure what I was thinking. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

4th Oct, 2014 at 08:55:43am

Dan, any updates?

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

774 Posts Member #: 6724 Post Whore Wootton Bassett |

4th Oct, 2014 at 04:08:36pm

Hi Paul,

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

4th Oct, 2014 at 04:57:50pm

Latest plot:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

10 Posts Member #: 10968 Member |

20th Nov, 2014 at 08:26:22am

Hi Dan, Hi Paul,

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

20th Nov, 2014 at 10:41:53am

The standard injectors will not support the airflow of a 1380. I suggest you go a lot higher, say 800cc/min.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

10 Posts Member #: 10968 Member |

20th Nov, 2014 at 12:16:19pm

End Pulse Timing is like mid puls +90 deg. I want to make sure, that the inner Inlet is closed, before start injecting the outer. Your values would be smaller by 90 degrees. I have a fuel pressure of 4.0 bar and set 500ccm per min. So I get a max PW of 4.6ms. At the moment, I have a max duty circle of 20%. But I also think it runs better with bigger injectors and less fuel pressure.

|

||||||

|

10 Posts Member #: 10968 Member |

20th Nov, 2014 at 12:22:47pm

Here two logs from the missfire

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

20th Nov, 2014 at 03:32:20pm

On 20th Nov, 2014 JumboHH said:

End Pulse Timing is like mid puls +90 deg. That's only true at one specific pulse width at a specific RPM. Any change in any parameter will make the timing wrong. If you're using a single pulse (as you will do with an MS3) you need to use the middle of the pulse timing. Otherwise, you can't have a stable timing and fueling. Jean |

||||||

| Home > MS Trials & Testing > MS3X MPi Trials | |||||||

|

|||||||

| Page: |