| Page: |

| Home > Show Us Yours! > A long standing love affair - rebuilding my 1380.. | |||||||

2233 Posts Member #: 9037 Post Whore Doncaster, yorkshire |

29th Mar, 2012 at 06:12:31am

There the same lower steadies as me, did you drill the subbframe with engine in? Audi s4 b5 - 470bhp & 486ft lbs

On 15th Mar, 2012 wil_h said:

Yes, Carl says he gets requests for rimming all the time On 30th Apr, 2012 Brett said:

yeah stick the bit in and give it a wobble  |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

29th Mar, 2012 at 07:14:48am

On 29th Mar, 2012 bennyy said:

There the same lower steadies as me, did you drill the subbframe with engine in? Yup, from underneath....carefully cos of front panel..! For every action there is an equal and opposite criticism. |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

3rd Apr, 2012 at 07:29:33am

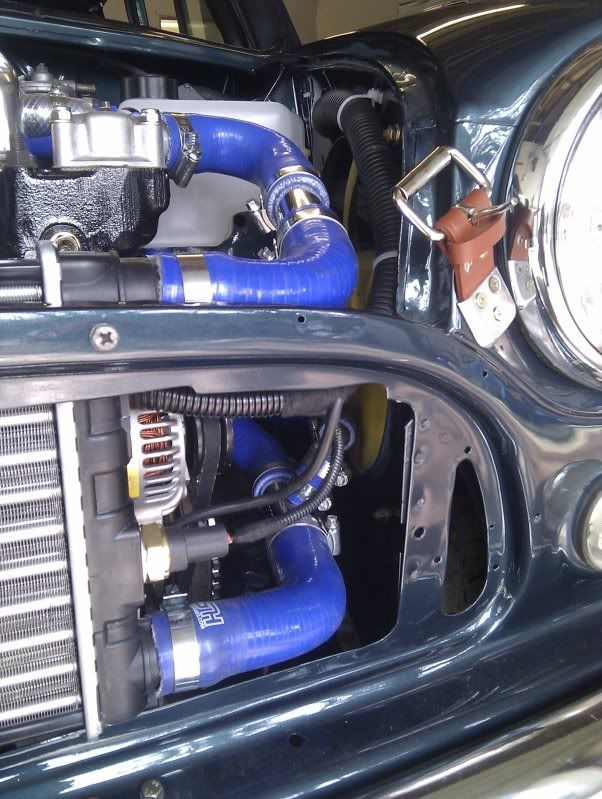

Few more days progress, started to build my loom into the car....

For every action there is an equal and opposite criticism. |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

6th Apr, 2012 at 04:33:44pm

Few more bits of wiring done, getting close to starting it up at last.!

For every action there is an equal and opposite criticism. |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

6th Apr, 2012 at 05:15:06pm

Thats looking very tidy! https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

264 Posts Member #: 8853 Senior Member Bristol |

6th Apr, 2012 at 05:26:01pm

Agree'd. I like the "control box". |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

10th Apr, 2012 at 09:52:54pm

Thanks guys.....as of yesterday loom now finished - connected up & tested, put a fuse in one circuit at a time, all working, apart from no cranking..! Found starter relay i'd fitted had pushed a terminal out of the back of its block, refitted, cranked to oil pressure, and *big grin* engine fired straight up, happy days.

For every action there is an equal and opposite criticism. |

||||||

361 Posts Member #: 114 Senior Member Porto/Portugal |

10th Apr, 2012 at 10:33:27pm

Nice work. i like the radiator :) Pedro Silva

|

||||||

|

614 Posts Member #: 2153 Post Whore kings langley |

10th Apr, 2012 at 10:41:11pm

are you getting rid of the crimp on connections? i find soldering and heat shrinking gives less trouble in the long run Speeding is like masturbating, everyone does it, but not all of us film it and put it on the internet

|

||||||

|

264 Posts Member #: 8853 Senior Member Bristol |

10th Apr, 2012 at 10:56:54pm

I read somewhere that over time, soldered joints can become brittle and break, causing problems. On a Suzuki loom I dismantled a while ago, I found, crimp connectors splicing into each other. Maybe something to think about |

||||||

847 Posts Member #: 6673 Post Whore Worral Sheffield |

10th Apr, 2012 at 11:18:14pm

looking very nice, i like the switch pannel. |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

11th Apr, 2012 at 05:47:48am

I'd never use soldering, best are crimped connection with heat shrink end built onto them, lot of manufacturers don't accept soldering as recognised repair due to the brittle/corrosive issue. Going to heatshrink over the ends of the connectors under the bonnet. For every action there is an equal and opposite criticism. |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

12th Apr, 2012 at 06:43:07pm

Dash all in now, had to rewire the rev counter, from high voltage pulse (diode adaptor) to straight off the edis unit, as it was dropping to zero at 3k rpm. Finally got my gearlinkage something like it, bled the clutch out, and had a play with the software too.

Edited by nikh667 on 12th Apr, 2012. For every action there is an equal and opposite criticism. |

||||||

847 Posts Member #: 6673 Post Whore Worral Sheffield |

12th Apr, 2012 at 07:06:29pm

what was the solution with the gear linkage? I fear I will have the same issue.

|

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

12th Apr, 2012 at 09:25:54pm

On 12th Apr, 2012 maccamcvey said:

what was the solution with the gear linkage? I fear I will have the same issue. I had an idea to use rose joints to support the linkage, as my lashed up drawing shows:

I quickly welded up this to support the portion of the linkage out the box - i had to drill a second set of holes further back to hold it solid against the gearbox casing:

Theres another one supporting the top section too. It's very crude but works okay now, i think the best way to get a good change is to take time & be precise/careful with the UJ's, which I have to be honest..i wasn't. For every action there is an equal and opposite criticism. |

||||||

|

614 Posts Member #: 2153 Post Whore kings langley |

12th Apr, 2012 at 09:32:40pm

i think its more likely that crimping is far faster and cost effective?

Speeding is like masturbating, everyone does it, but not all of us film it and put it on the internet

|

||||||

847 Posts Member #: 6673 Post Whore Worral Sheffield |

12th Apr, 2012 at 10:23:46pm

very nice, I have connected my bottom UJ directly to the role pin connecter thing so should reduce some movement there.

|

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

15th Apr, 2012 at 11:39:12am

Few more updated pics, got it rolling now, brakes bled, clutch bled & adjusted, few more jobs this week and it'll be MOT time For every action there is an equal and opposite criticism. |

||||||

478 Posts Member #: 9269 Senior Member Rotherham |

15th Apr, 2012 at 04:40:33pm

I like the gear linkage do you its going to make the gear change any better?

Craig

|

||||||

520 Posts Member #: 189 Post Whore Norway |

15th Apr, 2012 at 10:06:04pm

Thats a neat looking wireing and control box. I really like that :) www.shag.no |

||||||

520 Posts Member #: 189 Post Whore Norway |

15th Apr, 2012 at 10:10:15pm

Ohh, and do you have more pics of your trigger wheel and sensor?? www.shag.no |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

16th Apr, 2012 at 07:05:01am

Craig I think buying a kit if you can is probably the better way to go, i've got a tight gear linkage now but its taken an awful lot of mucking around, and also it's not adjustable so the engine pretty much gotta stay where it is. Have yet to try it properly on the road, so will see truly what it's like then.

For every action there is an equal and opposite criticism. |

||||||

520 Posts Member #: 189 Post Whore Norway |

16th Apr, 2012 at 09:05:20pm

Great. Where did you get the trigger wheel?? I am looking in to converting my engine wich also have a belt drive to KMS ignition, so needs a trigger wheel/sensor :) www.shag.no |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

16th Apr, 2012 at 09:33:21pm

It came supplied with the complete Megajolt kit, and is bolted to the outside of a normal damper type pulley - I had to place a thick washer in between the two so that the bolt didn't pull the trigger wheel against the pulley on the outer edge, but instead tightened it properly in the centre. For every action there is an equal and opposite criticism. |

||||||

99 Posts Member #: 9550 Advanced Member Cornwall, UK. |

23rd Apr, 2012 at 07:28:36pm

Last few bits done to the car now really, finished my breather setup off with an oil can as a catcher - I did nick this idea off one of you guys (can't remember who.!)..

For every action there is an equal and opposite criticism. |

||||||

| Home > Show Us Yours! > A long standing love affair - rebuilding my 1380.. | |||||||

|

|||||||

| Page: |

It's prob not going to be ready in time for having a go at first local hillclimb, but means i'll take a drive over to the Riviera Run the same weekend.!

It's prob not going to be ready in time for having a go at first local hillclimb, but means i'll take a drive over to the Riviera Run the same weekend.!