| Page: |

| Home > Show Us Yours! > Lightweight, uncomfortable, minimalist, fun. | |||||||

|

2370 Posts Member #: 719 Post Whore Horndean - Near Portsmouth |

19th Oct, 2008 at 10:50:27am

Hows the to-do list coming along James? Hopefully getting smaller!! |

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

19th Oct, 2008 at 12:08:19pm

well got the hose made up (took two hours when it should have taken 30 mins because of traffic!!)

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

19th Oct, 2008 at 11:00:20pm

ahhhhh well well well!!! what a weekend!!!

Edited by James_H on 19th Oct, 2008. |

||||||

|

628 Posts Member #: 1064 Formally Whyte_ben Horndean, Hampshire |

20th Oct, 2008 at 10:34:40am

Looking good mate.

|

||||||

|

2370 Posts Member #: 719 Post Whore Horndean - Near Portsmouth |

20th Oct, 2008 at 10:36:46am

On 20th Oct, 2008 Ben. said:

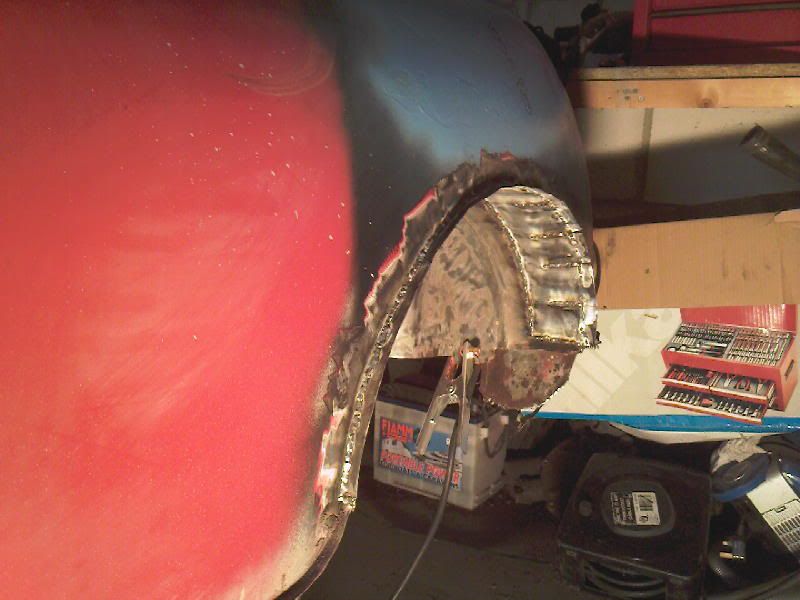

Looking good mate. Welding look strong which is what matters, and its going to be covered up with the arch's anyway! I got mine too hot when welding and now im having to filler all the side panel where its warped... It's ok, you can become an expert at it when you do mine for me, bitch Looking good James! Edited by richminiturbo. on 20th Oct, 2008. |

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

20th Oct, 2008 at 06:08:20pm

yeah, that was the good side! did the other side the same but it was already pretty warped for some reason, and the only thing i did different was on the good side i had a wet tea towel and kept the body above the weld nice and damp.

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

25th Oct, 2008 at 09:13:19pm

righttttttt....to do tomorrow (after rebuild the head for the pitbike now that i have ported it and opened up the head and thne measuring the cc's. anyway i'll get some pics of that and start a new thread!) is chop my top bulkhead out and get a nice miglia styleeee box in there.

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

1st Nov, 2008 at 09:07:07pm

riiiiiiiiiightoooo seeing as i found out that im skint as a mint sat on a peice of flint i think i might get some pics up of todays small progress.

|

||||||

|

628 Posts Member #: 1064 Formally Whyte_ben Horndean, Hampshire |

1st Nov, 2008 at 09:11:03pm

Looking good mate, keep it up!

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

2nd Nov, 2008 at 05:48:48pm

well a good day today |

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

17th Jan, 2009 at 08:17:00pm

been out there today chopping bits out of the shell.

|

||||||

368 Posts Member #: 362 Senior Member durham area |

17th Jan, 2009 at 08:44:07pm

its amassing how much you end up cutting out seems never ending looking good though all worth it in the end. love that straight cut scream!!!

|

||||||

|

4304 Posts Member #: 1321 Post Whore Wiltshire |

17th Jan, 2009 at 09:25:20pm

Ooooo, are those oversills on the shell? If so I would have them straight off and weld some pucka ones on. Or if there just non genuing normal sills stick some ventilation in them.

On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

17th Jan, 2009 at 09:46:43pm

dont worry, Andre has already pulled me up on that over on EFI. they are some of the panels that will be ordered when i have the funds... |

||||||

|

4304 Posts Member #: 1321 Post Whore Wiltshire |

17th Jan, 2009 at 09:50:17pm

Thats good then. I wouldn't want to see you completely restore the shell, then have a load more work in a couple of years sorting more rust:) On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

|

444 Posts Member #: 2885 Senior Member |

18th Jan, 2009 at 12:56:10am

Dude, how come there is a Picture of a toolbox in your garage?

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

18th Jan, 2009 at 09:25:43am

haha! being a mechanic i hate not having a tool where its supposed to be! if i have to root around for it thats wasted time!

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

28th Jan, 2009 at 09:30:38pm

well, ive been on a diet!!!!

Edited by James_H on 28th Jan, 2009. |

||||||

1733 Posts Member #: 1910 Post Whore Wilts |

28th Jan, 2009 at 09:37:40pm

Looking good. Not much more you could lose of the shell is there? On 15th Jul, 2009 fastcarl said:

the pissed up clown stood back up, did a twirl and left bollock naked, |

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

28th Jan, 2009 at 09:41:06pm

the front bulkhead triangles will go, the steering rack bracket will get attacked with a drill/hole saw. the tunnel will be modded at the front (exhaust clearance not weight saving) and then just little brackets and bits/bobs.

Edited by James_H on 30th Jan, 2009. |

||||||

|

784 Posts Member #: 912 Post Whore North Yorkshire |

28th Jan, 2009 at 10:12:39pm

Looking good,

I drill holes in everything..! |

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

28th Jan, 2009 at 10:14:55pm

well, im going to find out if ive gone to far the first time it see's some sprited driving i suppose!

|

||||||

|

458 Posts Member #: 1840 Senior Member Kings Lynn, Norfolk |

28th Jan, 2009 at 10:16:50pm

Bloomin hell, its looking bare, must nearly be able to pick the whole shell up by your self. |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

29th Jan, 2009 at 07:58:08am

Can you loose any more roof?? You can't need that much metal to bond a fibre glass/carbon fiber one to?? On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

3692 Posts Member #: 1833 Formally mini_majic Auckland, New Zealand |

29th Jan, 2009 at 01:21:19pm

i will definately be losign more roof. i just dont have a FG/Carbon one to hand to see how much i actually need.

|

||||||

| Home > Show Us Yours! > Lightweight, uncomfortable, minimalist, fun. | |||||||

|

|||||||

| Page: |

not fooking cheap though at over £400 and £30 a blade! luckily i just robbed it from work for the weekend, its the same as what the hospicals use to cut plasetrs off!

not fooking cheap though at over £400 and £30 a blade! luckily i just robbed it from work for the weekend, its the same as what the hospicals use to cut plasetrs off!

i will be using adjustable brace/anti-roll bars to stiffen everything back up and the cage will be tied in everywhere i can.

i will be using adjustable brace/anti-roll bars to stiffen everything back up and the cage will be tied in everywhere i can.