| Page: |

| Home > Show Us Yours! > lil grey | |||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

5th Mar, 2016 at 06:33:10pm

after seeing e5tus attack his car i thought why the hell not. now i know this is going to be obvious to you all but fak me this crap weights a lot!! after amazon priming some stanley chisels and them turning up being tiny i was dreading it but the 16mm (largest one) was amazing, and the smaller ones for helping to get going.

Edited by t@z on 6th Mar, 2016. |

||||||

2974 Posts Member #: 10749 Post Whore lowestoft suffolk |

5th Mar, 2016 at 08:48:24pm

Petrol or paint thinners will have the residue off nicely On 24th Oct, 2015 jonny f said:

Nothing gets past Dave lol NOTHING GETS PAST ME!!

1/4 mile 14.7 @ 96mph 12psi boost Showdown class A 2nd place 18.6 @ 69mph |

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

6th Mar, 2016 at 09:00:41am

Thats a really neat solution. In the 13's at last!.. Just |

||||||

428 Posts Member #: 10128 Senior Member Dorset |

6th Mar, 2016 at 01:59:31pm

On 5th Mar, 2016 t@z said:

need to get the crappy lil bits off as well was just going to use a wire brush or is there a better way? Satisfying job to get done isn't it! I'm using petrol, got a jerry can of stuff that's gone off and it's great for it. |

||||||

2974 Posts Member #: 10749 Post Whore lowestoft suffolk |

6th Mar, 2016 at 02:08:02pm

Its a hilarious job! The bits flying off everyhwere rikashaying off everything.. dont tell me ya didnt make 'peeoww' noises On 24th Oct, 2015 jonny f said:

Nothing gets past Dave lol NOTHING GETS PAST ME!!

1/4 mile 14.7 @ 96mph 12psi boost Showdown class A 2nd place 18.6 @ 69mph |

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

6th Mar, 2016 at 03:54:26pm

i didnt really have much of the pew pewing off bits however it was insanely satisfying and was really easy but i put that down to the cold.

|

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

28th Jun, 2016 at 02:03:10pm

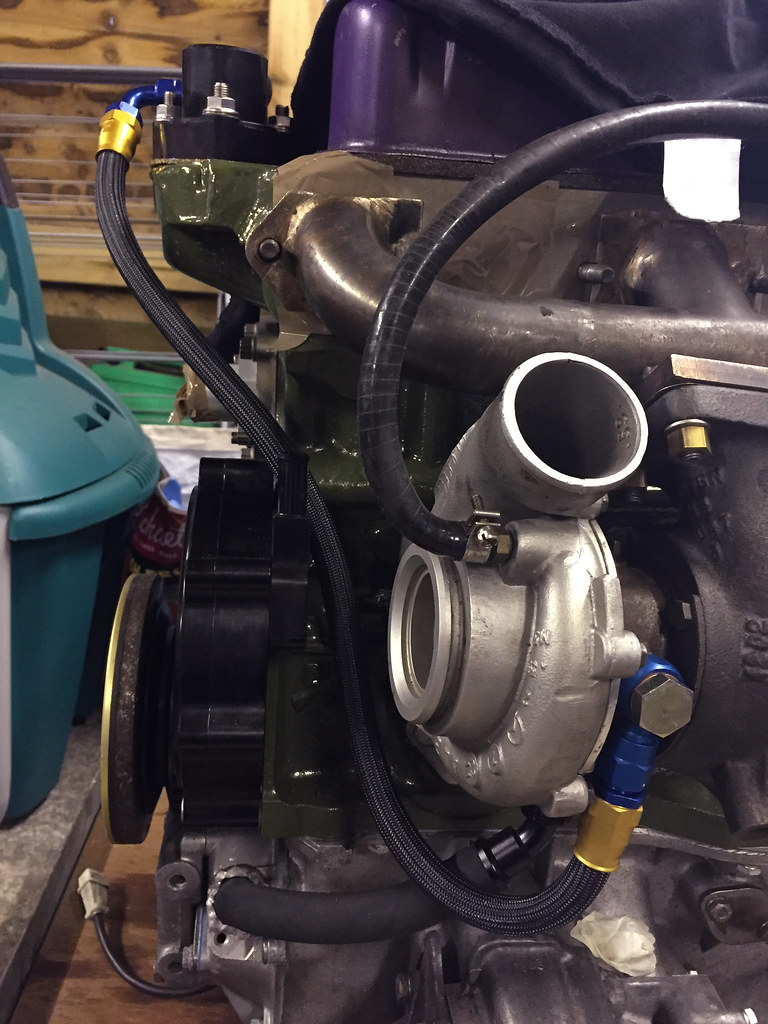

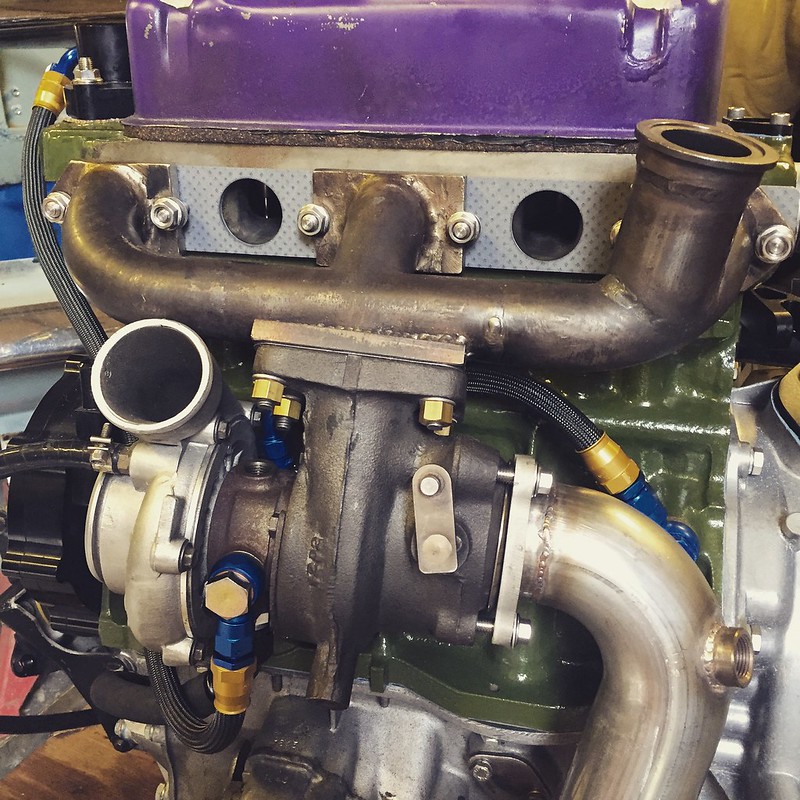

Small update. I don't really feel like much has happened mostly because off work and i can only get to think once a week so the moons have to allign perfectly for it all to fall into place.

|

||||||

|

940 Posts Member #: 1424 Post Whore Carnforth, Lancs |

28th Jun, 2016 at 04:27:16pm

Should there not be copper washers both sides of the banjo fitting....?

On 5th Mar, 2016 t@z said:

Feed this is super tight here mostly because there isn't much room on the bingo head for the exhaust downpipe.

|

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

28th Jun, 2016 at 04:51:45pm

Yes there should! Good catch, i will check this when next at the car :) Thank you! |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

28th Jun, 2016 at 08:19:53pm

I don't think you'll get proper circulation around the turbo with how you've got it piped dude. Both connections are made to the same side of the pump if you get my meaning. Your return should really be in the bottom hose.

13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

28th Jun, 2016 at 08:49:39pm

On 28th Jun, 2016 eden7842 said:

I don't think you'll get proper circulation around the turbo with how you've got it piped dude. Both connections are made to the same side of the pump if you get my meaning. Your return should really be in the bottom hose. Happy to be corrected otherwise tho you raise a valid point, tbh im not to sure myself now you mention it. i guess ur thinking that the pressure on the loop by the head take off will slow the return from the turbo or work against it? |

||||||

1755 Posts Member #: 8852 Post Whore leicestershire |

28th Jun, 2016 at 10:34:55pm

I'm thinking more of a neutral zone together rather than pump pressure help it around. 13.95 1/4 mile on a 2.95 fd. Carnt be that hard to beat! |

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

4th Jul, 2016 at 10:53:59am

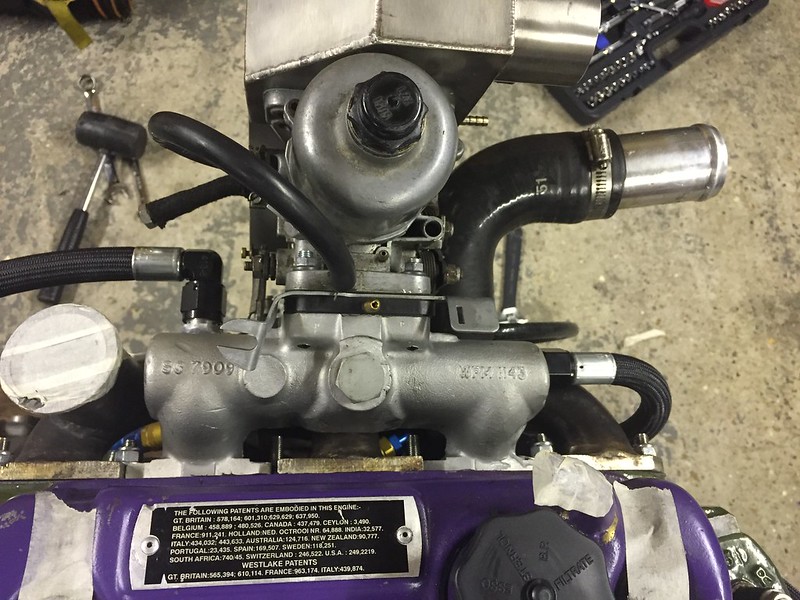

pathetic update....

|

||||||

2094 Posts Member #: 9894 Post Whore Dorking |

4th Jul, 2016 at 02:59:54pm

running next week?! |

||||||

4625 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

4th Jul, 2016 at 07:24:44pm

Looking good.

|

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

4th Jul, 2016 at 11:31:32pm

What's going on here with that breather in the side of the inlet manifold? This doesn't look right to me...

On 28th Jun, 2016 t@z said:

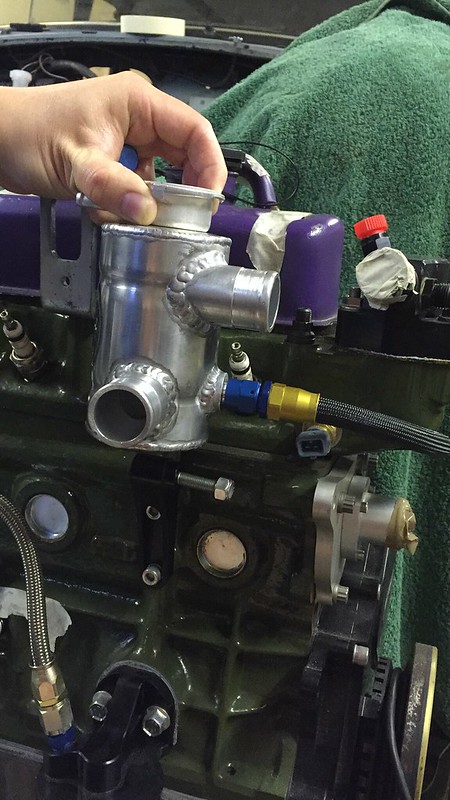

Another thing done was realising how tight it was for the breathers Lee helped me mill down and weld on these to the unlet for the breathers. ThinkAutomotive were top notch at helping me get the tubing made for these as orginally i was going to use standard rubber but it proved to not be flexible enough. Some weird custom ish set up on the fancy hose and AN fitting. Hopefully this is simple enough

On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

5th Jul, 2016 at 08:09:44am

Looks like hes just using the water heating path to neaten the pipe work up?

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

5th Jul, 2016 at 08:18:16am

Breathers look really neat. But are they sized large enough, in particular the 90 deg fitting off the inlet pipe, they can be really small ID.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

5th Jul, 2016 at 01:23:26pm

thanks gents. sadly work and being away will keep me from the car so no progress for 2 weeks. but i have things to think about as above :)

Edited by t@z on 5th Jul, 2016. |

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

2nd Sep, 2016 at 09:53:03am

So after getting the engine in and sizing up the radiator.... realising how little space there was and some angle grinding. Out the engine come again.

|

||||||

4625 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

2nd Sep, 2016 at 12:28:37pm

Good effort. That radiator looks a nice fit, what's it off?

|

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

2nd Sep, 2016 at 04:42:43pm

On 2nd Sep, 2016 Turbo Phil said:

Good effort. That radiator looks a nice fit, what's it off? Phil. it is just your standard cinq rad. nothing fancy :) |

||||||

|

166 Posts Member #: 8952 Advanced Member Athens Greece |

8th Sep, 2016 at 05:40:17pm

Hi great effort, but that rad is the with the round pipes, the other one with the v fins is much better at cooling.

|

||||||

2054 Posts Member #: 452 Post Whore Chester, UK |

18th Sep, 2016 at 11:32:00am

On 8th Sep, 2016 giannoutsos said:

Hi great effort, but that rad is the with the round pipes, the other one with the v fins is much better at cooling. John which rad you on about? i've had this rad for a good 1.5 years just sitting in the garage so if there is a more efficient one im up for that |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

18th Sep, 2016 at 12:40:47pm

There are two different versions of the Fiat cinq rad depending on the year.

Schrödinger's cat - so which one am I ??? |

||||||

| Home > Show Us Yours! > lil grey | |||||||

|

|||||||

| Page: |