| Page: |

| Home > A-Series EFI / Injection > 1312cc TI | |||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

25th Oct, 2014 at 10:06:17am

On 24th Oct, 2014 Paul S said:

Did you know that you can connect the 0-5v output from your wideband directly into the ECU ?  Yes, I started off this way with the 998 NA, but ran out of MS2 inputs, Hence why I moved the 2 analogue inputs from the MS2 to the IOx in the first place. In one of my first posts on the 998 NA injected car I had a hell of a time with spikey signals from the LC-1’s, which was partially resolved when I renewed what was obviously substandard wiring on my part. But it was not until after I moved from analogue input on either MS2 or the IOx to digital through the IOx that I got what I saw as a nice clean trace on the AFR’s, at least that I was happy with. I too have done thousands of miles in the 998 NA with fully sequential port injection, improved performance massively (my perception, as it was never put on a rolling road before or after the changeover), increased fuel efficiency dramatically and improved the emissions, but I have also had my share of problems in getting it work reliably – Mostly down to my build mistakes. There was a lot of head scratching and getting input from those of you that had already worked out the basics before I started playing with it. Depending on your abilities or prior knowledge this type project is either extremely complicated or not. IMO there is a lot to learn before you get started with converting to Injection, regardless of which ECU or fuelling regime you decide to use, if your knowledge is as limited as mine. For me it’s been complicated. I started out doing this as a challenge to myself to learn something new. I’ve had to do a lot of reading and ask a lot of questions to understand the basic’s. I still get lost now with some of the more in depth discussions, though try to keep up. That said, I think I was successful with the 998 NA and was more than happy with the results. Although converting to injection on a turbo engine is more complicated than the NA (Using the Siamese code), this particular build is more complex still. That’s because it is not just simply Fuel injecting: The traction control adds more complexity, not only in the physical wheel sensors, but the knock on effect with the ECU – Hence why I have run out of ports on the MS2. A lot of the data I intend on gathering, half of which can be seen in the MLV log in the first post, is not necessary, IMO, for successful implementation of fuel injection. It is ultimately intended to help me to understand what’s actually going on in there. Hopefully it will help to make the conversion from carb to Port injection easier for those who do not want to “learn a different language” or at least make them think more about alternates and probably learn from my mistakes. I also intend on using some of that data moving forward as my dash board. Oil pressure, fuel level, fuel pressure all through the MS/ IOx. I have no dials/ gauges other than the Speedo. Anyhow, that’s just me rambling on. I appreciate all the help you are giving and feedback so far to what maybe some stupid or basic question. And thanks for the feed back on the car – which I have just seen since starting this post. Edited by Graham T on 25th Oct, 2014. ’77 Clubman build thread

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

25th Oct, 2014 at 10:37:14am

On 25th Oct, 2014 Paul S said:

I think we need to do some testing to verify the potential wideband issues. I'll start a new thread rather than clutter this one up. Agreed, but to to add one last comment by me on this particular subject, I forgot to mention last night (Graham has referred to it since) the reason a digital input is essential in both mine and Graham's setup is that the MS2-E code only allows two CPU pins for a second O2 analogue (JS4 and JS5) and we both use those pins for TC. And digital wideband is no big deal if you use an IOx with the MS2 (although limited to Innovate or 14point7 products). And for what Graham and I are doing the IOx is essential as the MS2 just doesn't have enough I/O (and an MS3 even with the MS3X add-on still isn't enough for what we are doing). It's true that even with an IOx you could still put the inputs in analogue - I did for a while before I ditched TechEdge in favour of 14point7 - but if you have a digital compatible wideband, using an analogue input would be like buying a 1080p 50" plasma and a BluRay player and still buying your films on DVD.... This thread is about a more complex build, not a basic one. I don't think people should be put off a more basic port injection system just because we are talking about a more complex one here. I have seen the difference analogue vs digital, Phil mentioned it recently in the dual wideband thread, and as Jean says it's been mentioned on the MS-E forms, but I'll elaborate on your other post. Schrödinger's cat - so which one am I ??? |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

18th Sep, 2015 at 12:55:42pm

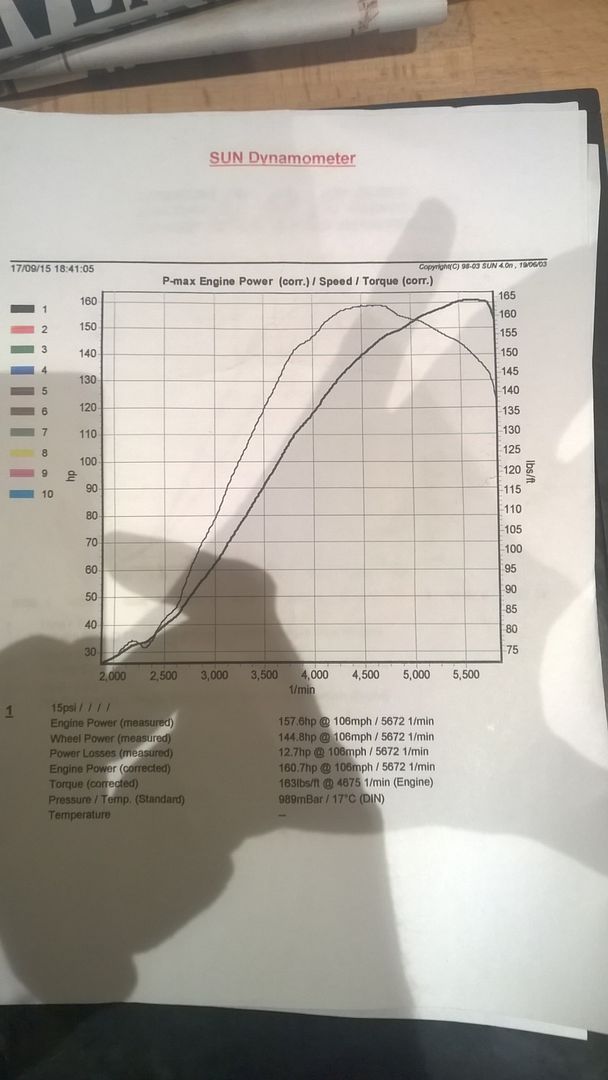

So, first rolling road session yesterday for the coupe (and the first time I’ve ever actually been at one.

’77 Clubman build thread

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

18th Sep, 2015 at 01:33:27pm

Excellent result! That is good power for the boost. In the 13's at last!.. Just |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

18th Sep, 2015 at 02:38:15pm

Looking at that graph, that should be a really nice car to driver. Fairly smooth all the way up to a decent point in the rev range. On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

| Home > A-Series EFI / Injection > 1312cc TI | |||||||

|

|||||||

| Page: |