| Page: |

| Home > Show Us Yours! > TwinKam 16v Sprint Car update 19/11/15 | |||||||

3249 Posts Member #: 1194 Post Whore Shropshire. |

7th Apr, 2014 at 07:11:30pm

Glad to hear it! |

||||||

1425 Posts Member #: 9199 Post Whore Lancashire |

7th Apr, 2014 at 08:34:59pm

nice looking mini, glad you dumped the vtec...... What the mind can conceive the mini can achieve

|

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

10th Nov, 2015 at 07:41:17pm

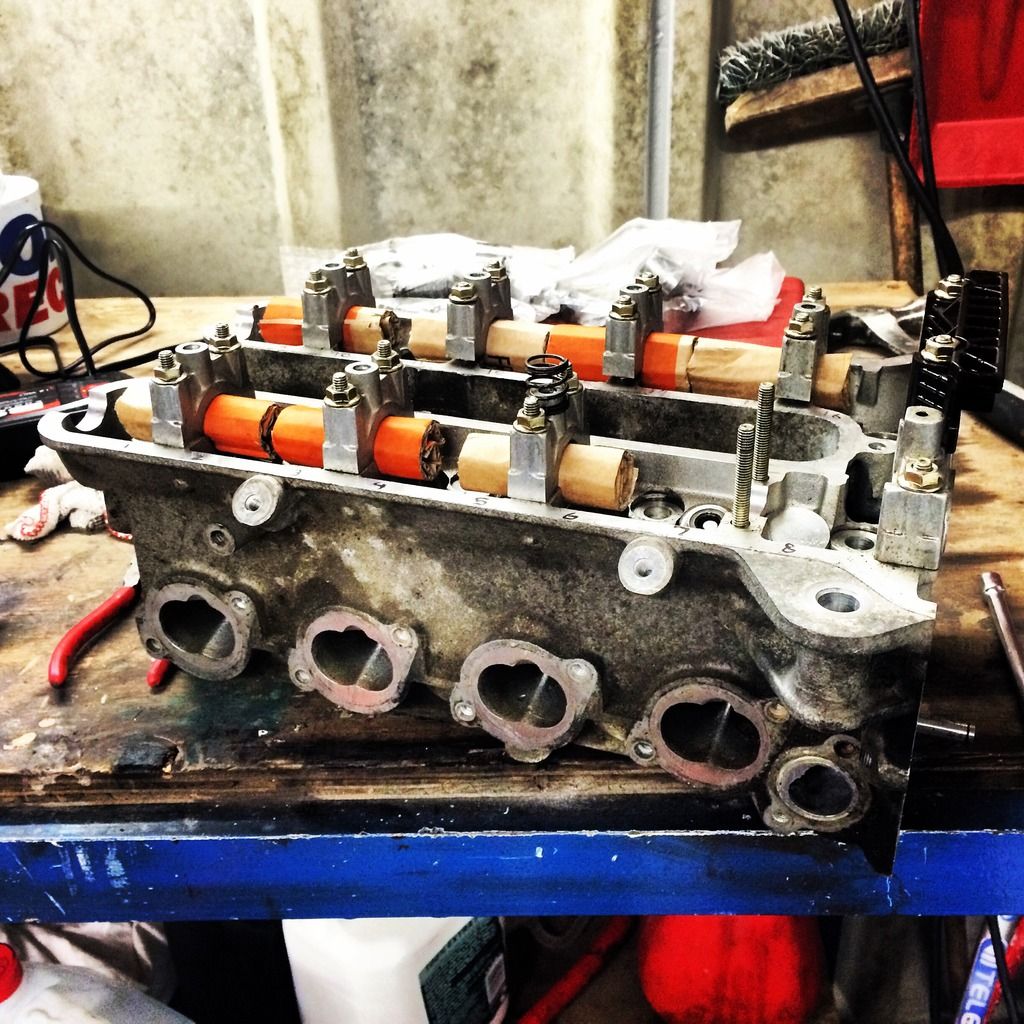

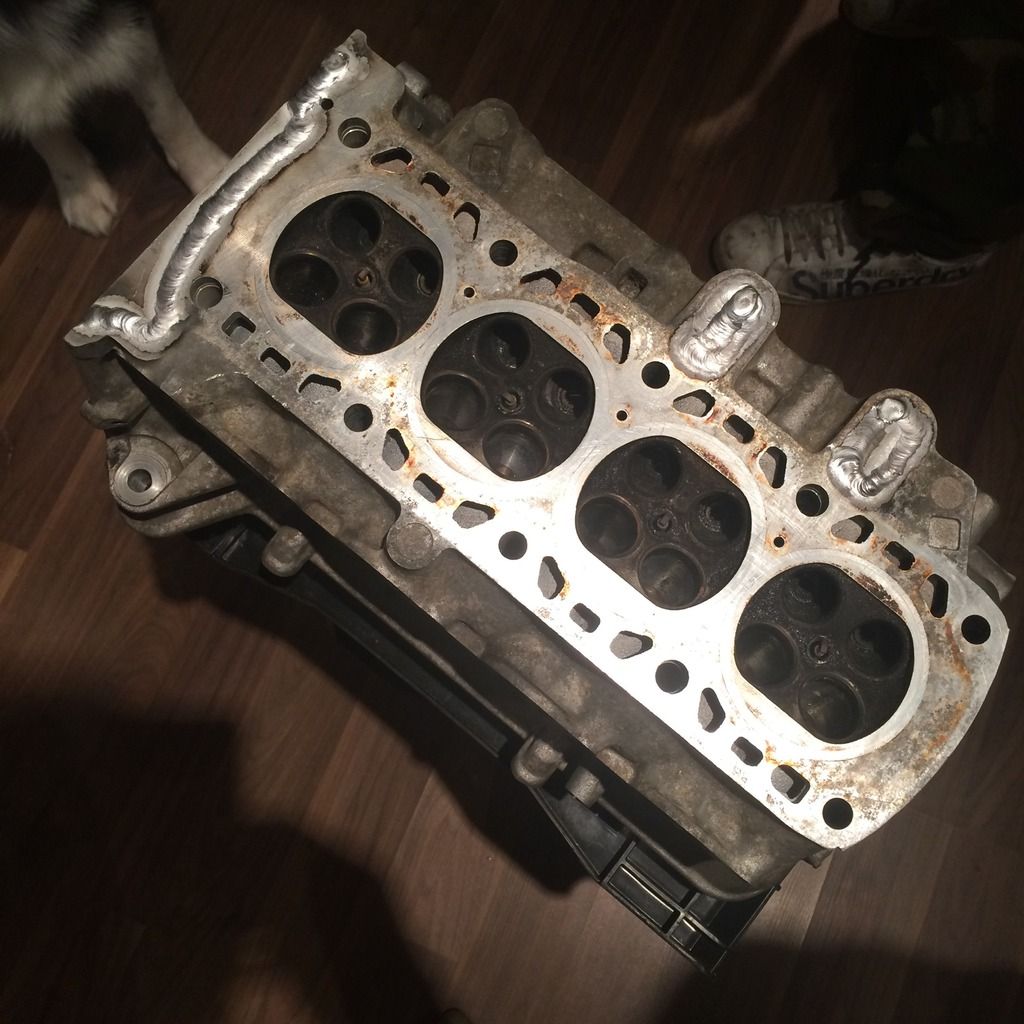

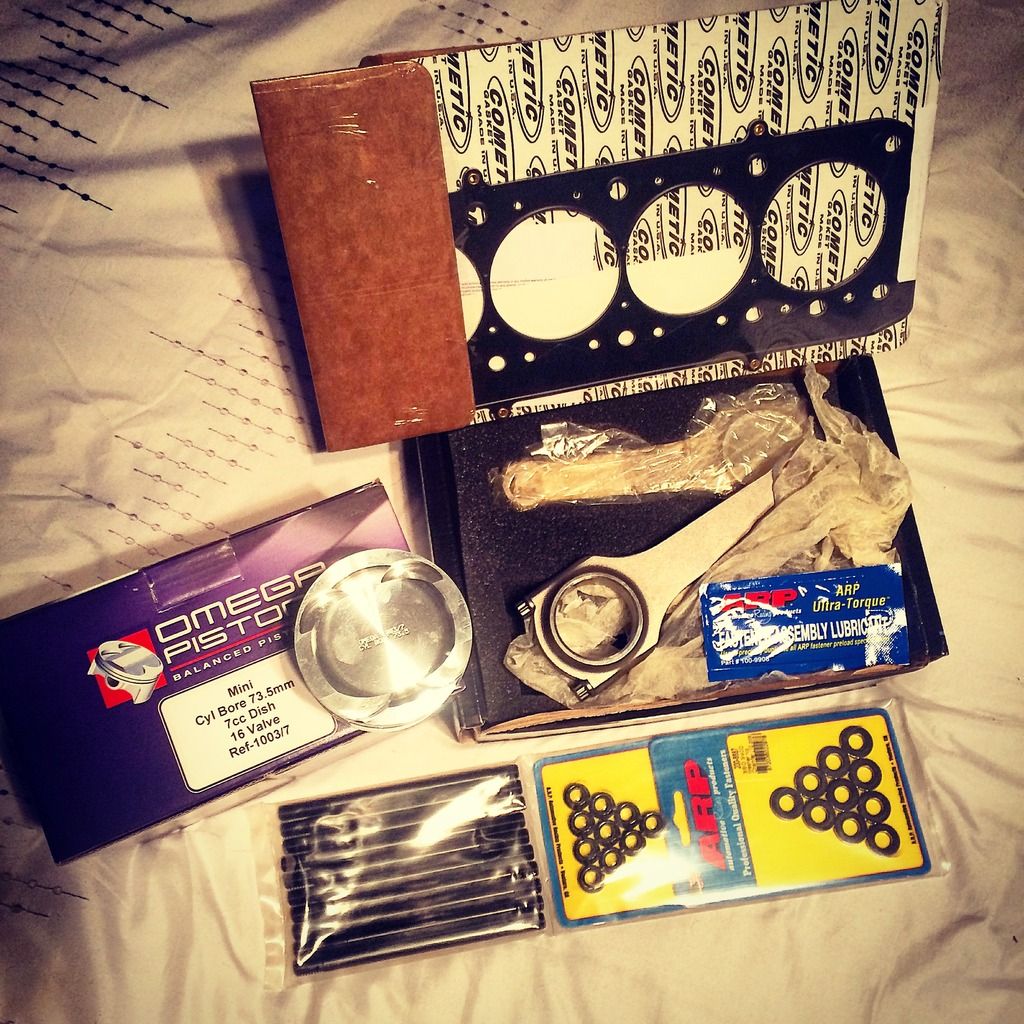

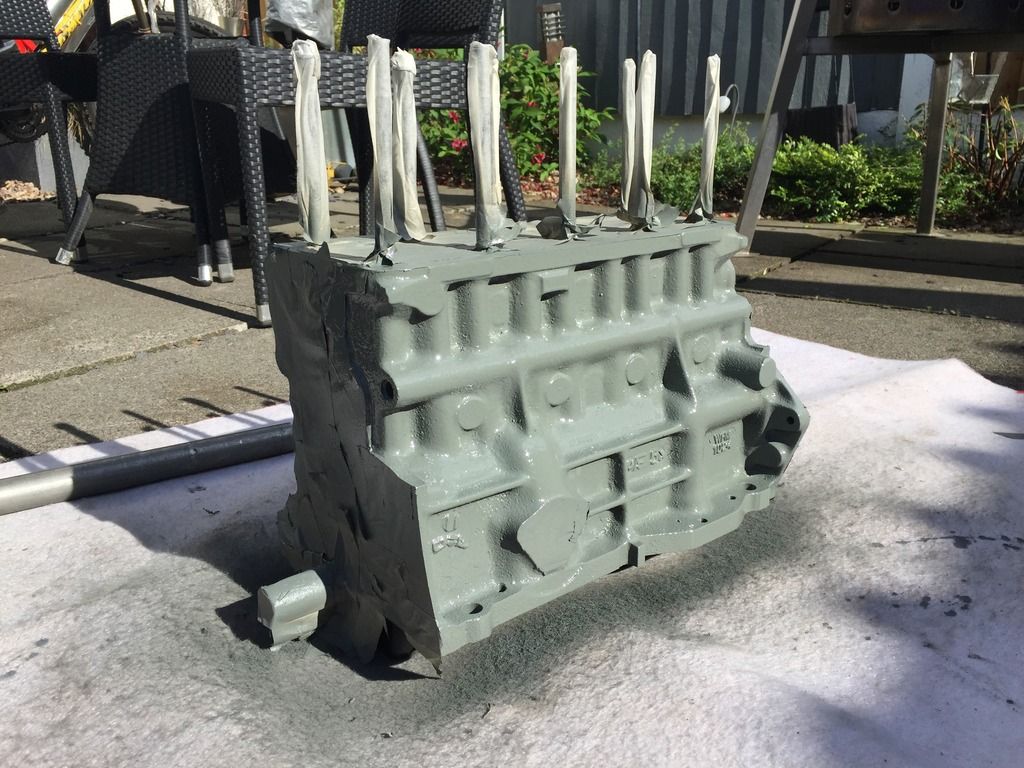

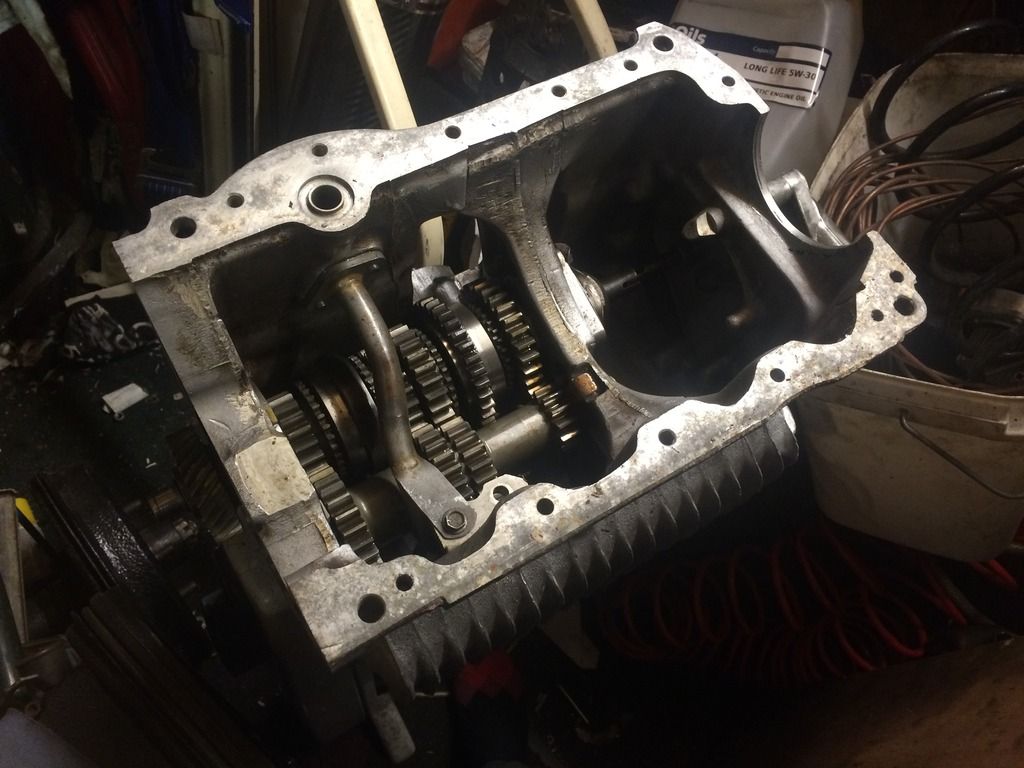

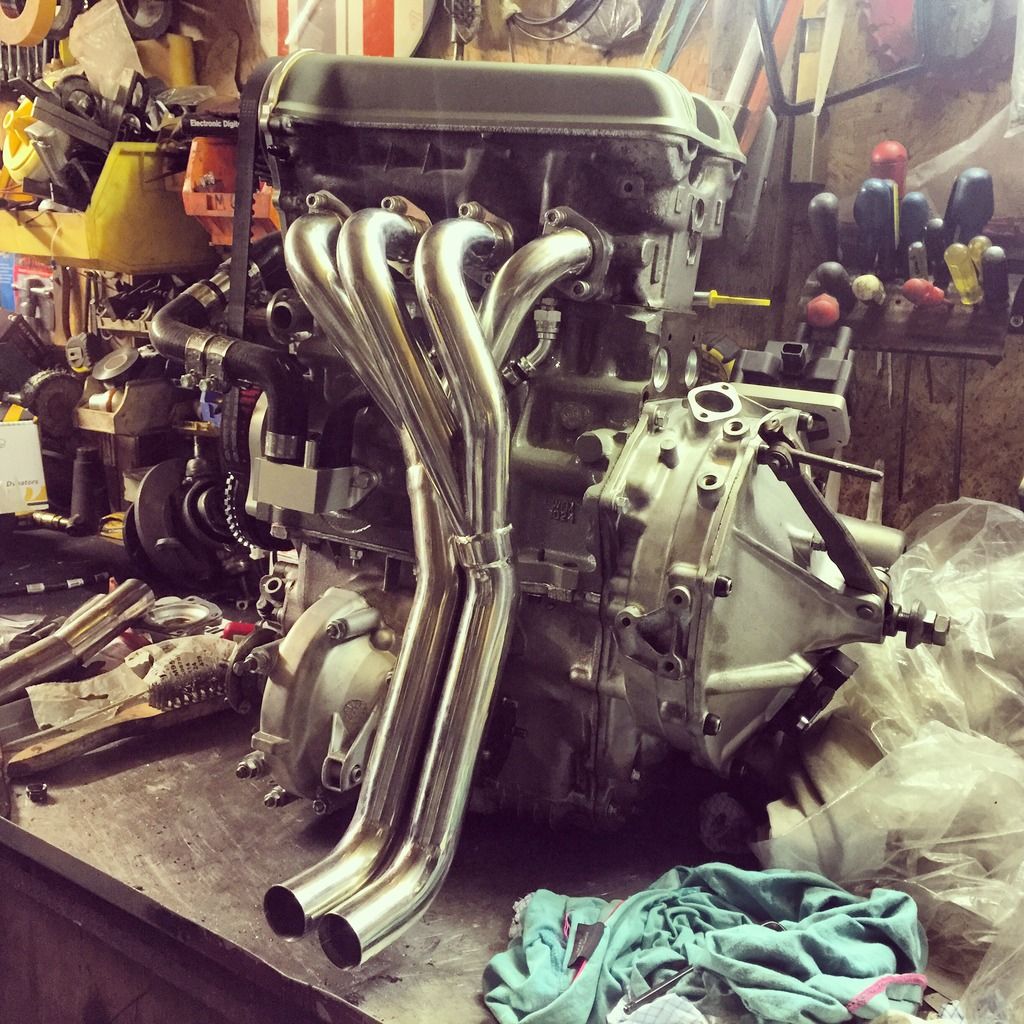

Hi all, a rather large update coming up!!

Edited by harry_orridge on 10th Nov, 2015. |

||||||

2742 Posts Member #: 637 Post Whore Hertfordshire |

10th Nov, 2015 at 07:43:03pm

Nice crank mate My build thread..

|

||||||

2974 Posts Member #: 10749 Post Whore lowestoft suffolk |

10th Nov, 2015 at 07:44:41pm

A the pics are of the crank?? Lol dammmmn On 24th Oct, 2015 jonny f said:

Nothing gets past Dave lol NOTHING GETS PAST ME!!

1/4 mile 14.7 @ 96mph 12psi boost Showdown class A 2nd place 18.6 @ 69mph |

||||||

10021 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

10th Nov, 2015 at 07:46:15pm

That's a lot of crank If something is worth doing, it's worth doing half of. |

||||||

|

940 Posts Member #: 1424 Post Whore Carnforth, Lancs |

10th Nov, 2015 at 07:51:10pm

He's proud of his crank, leave him alone! |

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

10th Nov, 2015 at 07:53:09pm

HAHA what an idiot, copied and pasted all the same photo, edited now lol. Face palm! |

||||||

2742 Posts Member #: 637 Post Whore Hertfordshire |

10th Nov, 2015 at 08:36:51pm

Looks good mate.

My build thread..

|

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

10th Nov, 2015 at 08:54:35pm

Thanks mate, hmm yeah I bought them off here second hand I wondered if they' would be too slippy I'll try them if there no good I'll stick some grip tape on the pedals instead. |

||||||

2742 Posts Member #: 637 Post Whore Hertfordshire |

10th Nov, 2015 at 09:09:11pm

I got a set without throttle pedal.

My build thread..

|

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

10th Nov, 2015 at 10:15:40pm

Looks good mate! I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

2094 Posts Member #: 9894 Post Whore Dorking |

10th Nov, 2015 at 10:39:49pm

looks very nice |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

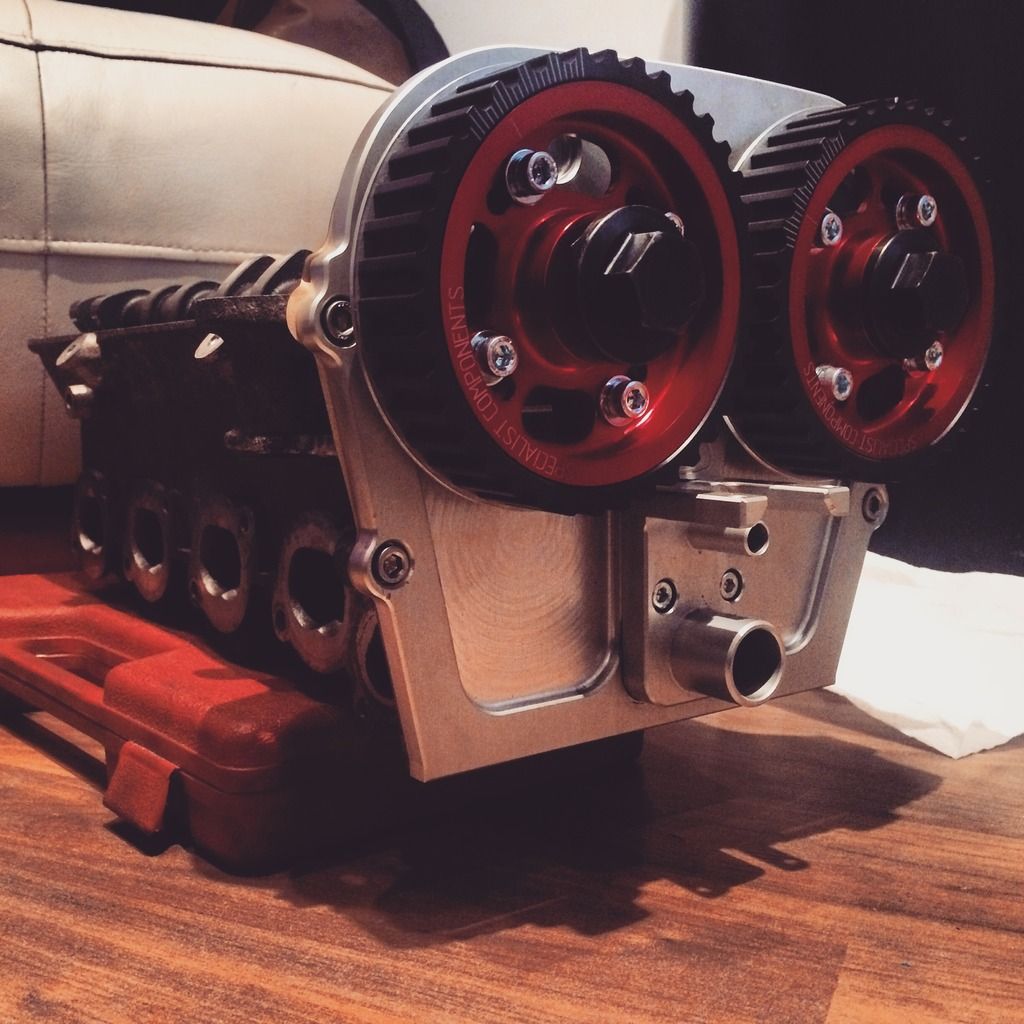

11th Nov, 2015 at 07:56:40am

You've spent a lot of Tim and money on that engine. Don't waste it by fitting the SC trigger wheel, they slip meaning your timing changes dynamically. Could end in disaster... On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

1030 Posts Member #: 1291 Post Whore Suffolk / Birmingham |

11th Nov, 2015 at 11:18:17am

They dont if you do them up tight |

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

11th Nov, 2015 at 05:38:51pm

Andy your not the first person to tell me that, however the MED crank pulley apparently didn't fit with the kit which is shit! :/! I'm going to drill and pin it when it's set up!

|

||||||

|

4304 Posts Member #: 1321 Post Whore Wiltshire |

11th Nov, 2015 at 08:11:40pm

Now that is a bargain, what cams are you running? On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

107 Posts Member #: 10760 Advanced Member Derby |

12th Nov, 2015 at 11:13:18pm

Looking good Harry!

|

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

13th Nov, 2015 at 08:32:58pm

Just standard lt cams at the moment however, I'm going to swap them for a set of RS ones before it goes to be set up!

|

||||||

3074 Posts Member #: 1348 Post Whore wakefield West Yorks |

13th Nov, 2015 at 09:45:34pm

Love it . |

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

19th Nov, 2015 at 08:44:25pm

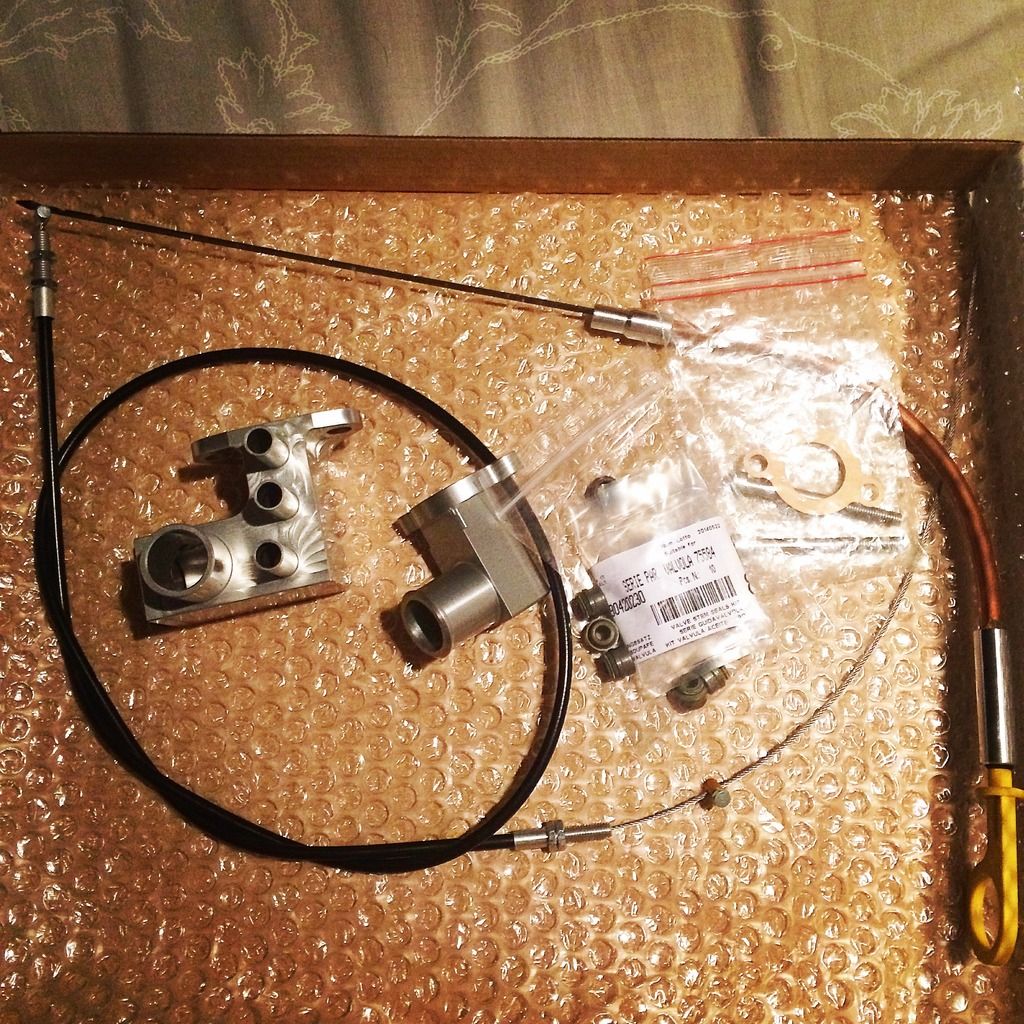

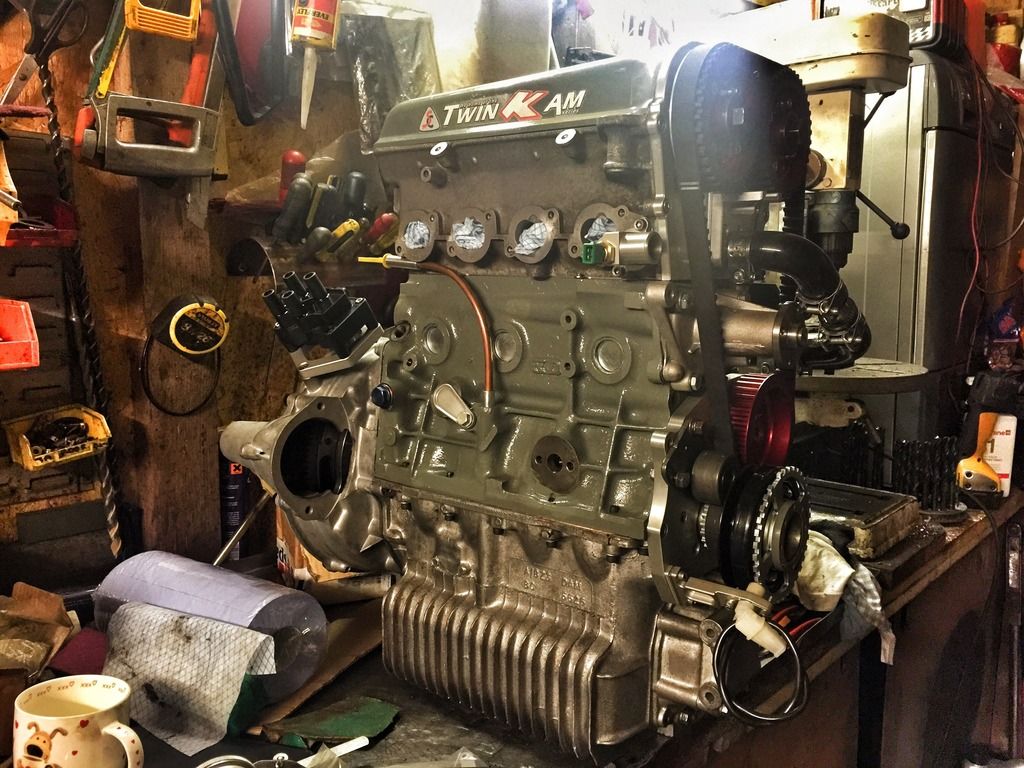

Another small update

|

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

19th Nov, 2015 at 09:03:55pm

This looks sweet!! Makes me want to build the 16v I have sat in a box in the shed lol I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

132 Posts Member #: 9142 Advanced Member Nottingham |

19th Nov, 2015 at 09:19:34pm

Thanks a lot! Get it built!! 16v turbo mk1 |

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

19th Nov, 2015 at 09:34:44pm

I have bigger things to sort out first I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

1030 Posts Member #: 1291 Post Whore Suffolk / Birmingham |

19th Nov, 2015 at 10:10:22pm

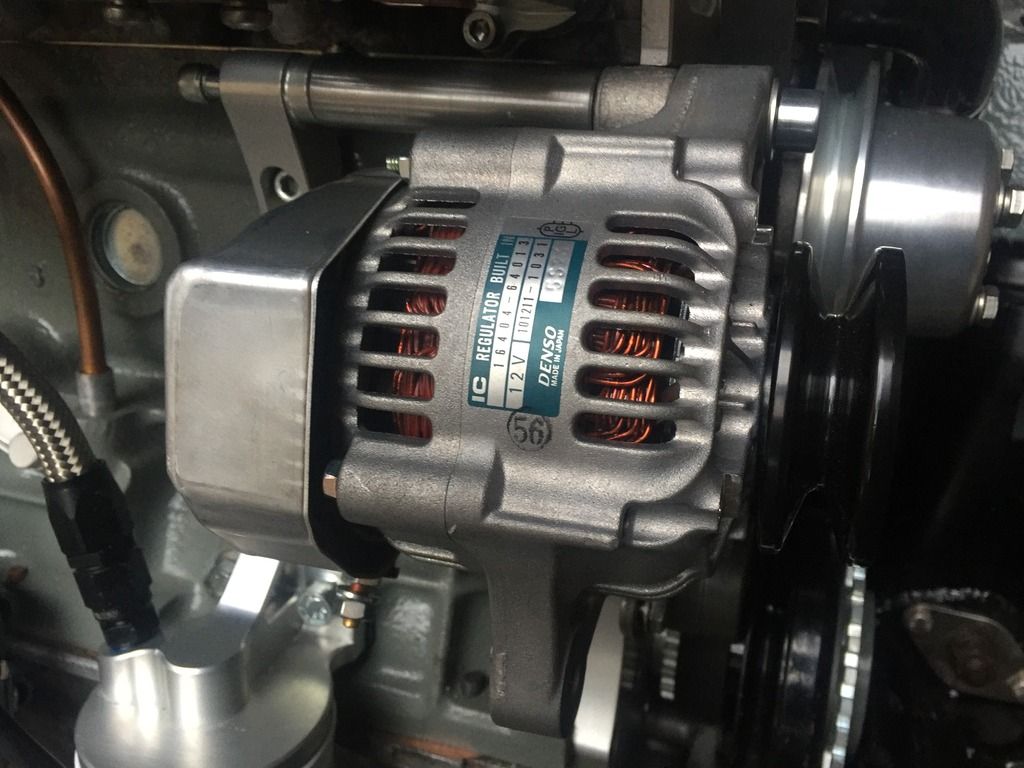

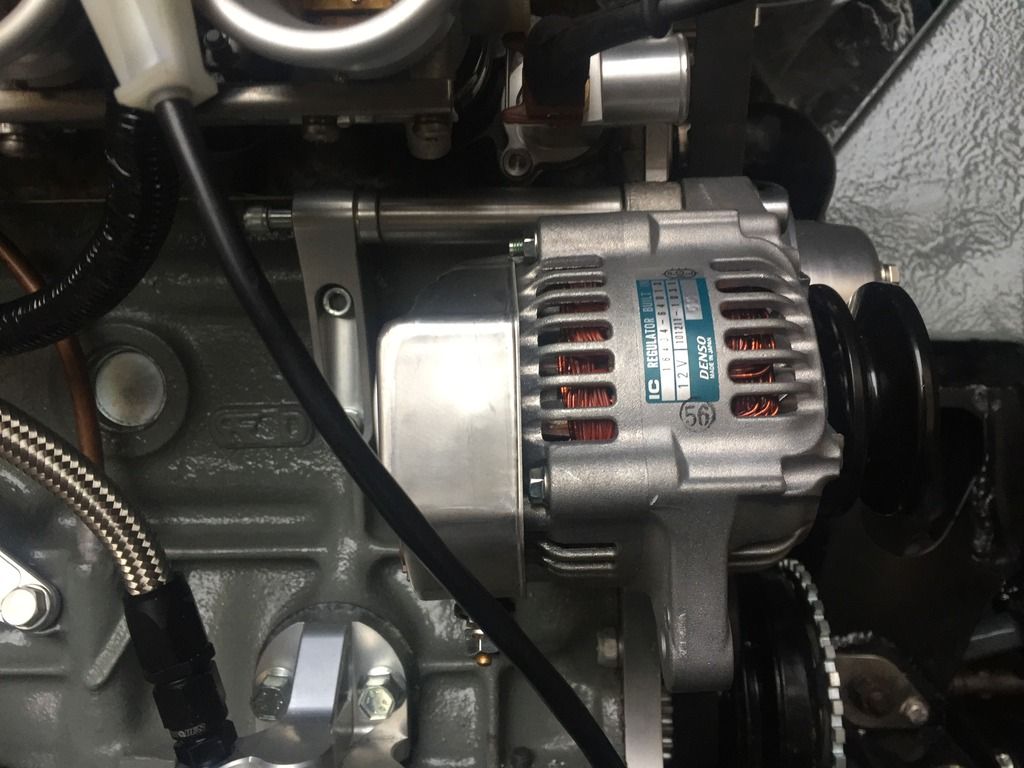

Nice, the alternator looks like the one I have. Much better fit than most. I made a enlarged pulley to under drive it a bit and at the same time that helped to correct some of the offset. |

||||||

| Home > Show Us Yours! > TwinKam 16v Sprint Car update 19/11/15 | |||||||

|

|||||||

| Page: |

.

.

!! I want nothing more than a mk1 shell to put this in!

!! I want nothing more than a mk1 shell to put this in!