| Page: |

| Home > Show Us Yours! > Turbo Cooper - floor repairs | |||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

11th Jul, 2014 at 09:01:58pm

some nice little touches here, i do like the damper pully 36-1 cutting tool

Edited by Brett on 11th Jul, 2014. Yes i moved to the darkside |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

12th Jul, 2014 at 04:04:44pm

On 11th Jul, 2014 Carlzilla said:

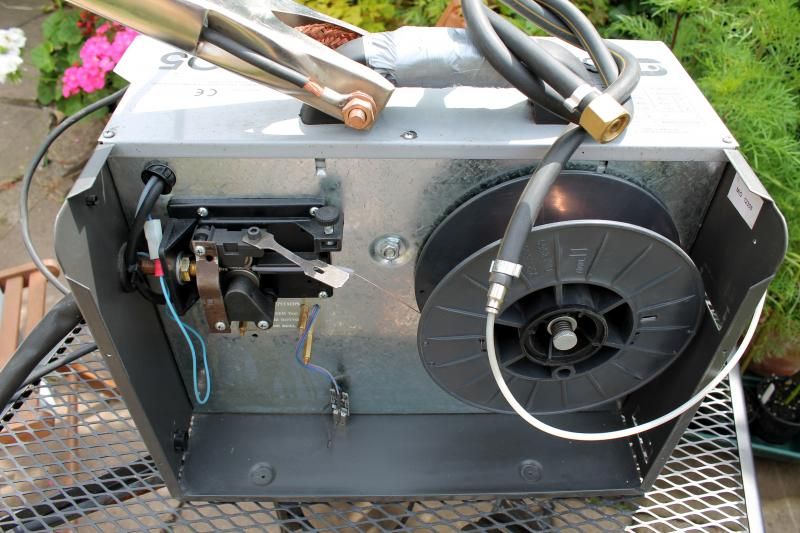

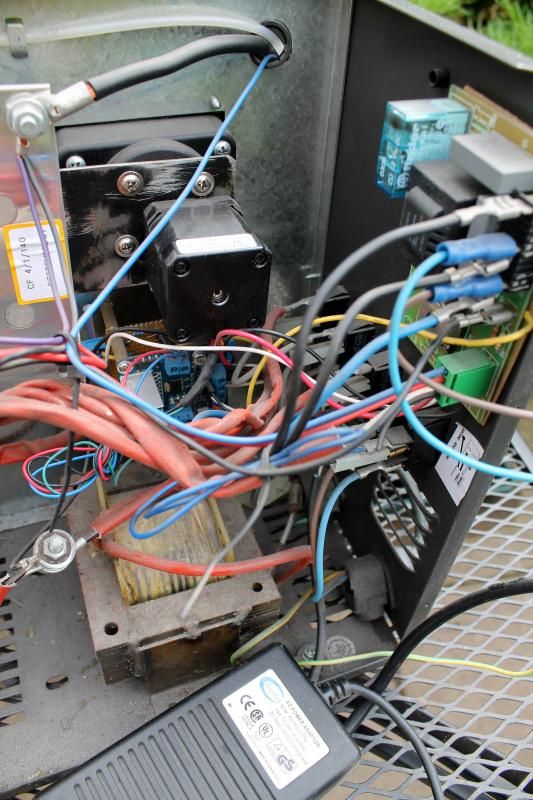

Some good ideas in here and ingenuity (sp?) but I too have a SIP welder which ive modded, but yet to set it up yet so I wont know how well it works, added a separate PSU for the wire feed motor which adds motor braking, along with the wire feed strap. The older SIP Migmates are sinful excuses for welders. Modding them makes such a difference. I'd happily buy an older 150A / 170A model for next to nothing and do the mods you've done. I've not documented anything I've done to mine (105 Amp Migmate) yet, so here's a 1 post summary in case it helps anyone (There's plenty more info around the web). The first three make a huge difference: 1) 24V PSU and relay for the motor and wired the relay to provide motor braking (shorts the motor leads when the relay is open) 2)Strap holding the drive wheel and tensioner wheel together. Without it the two wheels touch each other instead of gripping the wire! 3)Cheap plastic wire liner replaced with steel liner - much less drag on the wire; wire speed doesn't vary as much when you reposition the torch cable. (I suspect the steel liner is not working well with Alu wire but not looked into it properly) 4)Shaved the tensioner spring to about a 1/3rd of it's width. The drive wheel is driven by a square shaft that wasn't centred in the wheel. In the photo below, I've pulled the spring out from under the adjuster knob, and when turned on, the free end of the spring moves a couple of mm up and down each revolution. I can't fix the drive wheel, so I reduced the spring rate so the tension varies less over each turn. You also need to tweak the spring upwards to pre-load it a bit too. 5) Better earth clamp. 6) Found a rent-free gas supplier and stopped wasting money on the disposable canisters.

After all that, I had a very good welder. I went one step further and replaced the motor with a stepper motor and Arduino controller. The motor speed is as precise as it gets and I have a load of features I want to program in (someday). The Arduino and stepper motor was interesting to learn and works great, but in reality the mods listed above make an great welder.

I bit of a mess, but it's one of those projects that's never finished! |

||||||

3673 Posts Member #: 9300 Post Whore Quarry Bonk |

12th Jul, 2014 at 05:01:13pm

Looks tidy, I could still do with a better clamp tbh, I had an old gasless mig which died, got a free 150T that needed some serious love and a new case, and combined the two haha. I picked up a different type of PSU, i can tweak the output voltage but I still think it needs a better motor really.

On 26th Jan, 2012 Tom Fenton said:

ring problems are down to wear or abuse but although annoying it isn't a show stopper On 5th Aug, 2014 madmk1 said:

Shit the bed! I had snapped the end of my shaft off!! 17.213 @ 71mph, 64bhp n/a (Old Engine) |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

12th Jul, 2014 at 05:57:01pm

On 11th Jul, 2014 Brett said:

some nice little touches here, i do like the damper pully 36-1 cutting tool how have you attached the big silicone 90 to the top of the manifold? Thanks Brett. The manifold lip is about 102mm / 4". I've made a 4mm Alu plate that has rounded edges and diameter is 2.5mm wider than the manifold lip; It screws down using the 3 bolt holes for original airbox and It will be spaced 2-4mm above the manifold.

When I made it, I think I had an idea that lots of holes would help even out the air flow into the manifold (Just a theory that I have no way to test). Worst case, the total area of all the drilled holes is greater than the area of the throttle body so shouldn't cause a restriction, and help keep the plate strong as it's only held down with 3 bolts .

In the second pic, I've turned the injector plate through 180 degrees to move the silicone hose further back in the engine bay. I've still got to do another trial fit in the engine bay soon, so I'm just seeing how I can tweak it so I don't run out of room. It's sitting a bit higher than the original KandN filter, which was already a tight fit. The main problem is how to seal around the injector connector - I haven't decided yet On 11th Jul, 2014 Brett said:

does the ms2 use the standard sensors from the spi? never really looked into it At the point I left it, I had nearly everything working. I had a plug and play ECU that looked the same as, and was interchangeable with the Rover MEMs unit. TPS - yes Coolant temp - yes Air temp -yes SPI timing wheel on back of flywheel - yes, I think you need to use the MSEXTRA firmware as that has a 36-2 timing wheel option (IIRC) Narrow band Lambda - yes, but I used a wideband 02 sensor and controller which outputs 0-5V to ms2. Either should work. * Other, non sensor stuff * Tach signal to display - yes Immobiliser - yes stepper idle control - I little bit of work. Needed a handful of FETs on the proto area of the board. Original ECU casing - yes. Needed to mount the MAP sensor on the underside of the board Coolant temp indicator on dash - NO / I don't know yet! I was still tuning last time I used it, so had the temp on laptop screen. When my engine went bang, coolant was spot on on 82deg, but oil temp was through the roof and I didn't know. In hindsight, there were clues, but Lesson learnt the hard way. I had intended to picture and document how to make a plug and play replacement for the SPI - if anyone thinks this would still be useful, let me know and I'll get it written up in detail. On 11th Jul, 2014 Brett said:

what fuel pressure does it run ? its 1 bar for the spi isnt it? Yep, regulator in the manifold runs at 1 bar by default. I'm thinking that because it's inside the turbo hosing, it could easily be made to 'sense' the boost pressure and stay exactly 1 bar over that. Fuel pump can hold a static pressure of 3bar. (Don't know how flow rate would affect that, or even whether the pump would last 5mins at that pressure) Edited by PhilR on 16th Jul, 2014. |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

12th Jul, 2014 at 06:10:47pm

On 12th Jul, 2014 Carlzilla said:

Looks tidy, I could still do with a better clamp tbh, I had an old gasless mig which died, got a free 150T that needed some serious love and a new case, and combined the two haha. I picked up a different type of PSU, i can tweak the output voltage but I still think it needs a better motor really. Nice work - Much tidier than mine! Might be worth squirting some contact cleaner on the motor brushes and use a steel cable liner so motor doesn't have to try so hard. |

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

12th Jul, 2014 at 08:43:44pm

excellent mate, its nice to see the custom parts and tools it shows that not everyone is purely copying whats already been done

Yes i moved to the darkside |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

27th Sep, 2014 at 10:40:44pm

I've changed direction with this slightly. I've had a rethink about some of the work I've done and I'm not happy with the way I'd pocketed the 998 block, so I've gone back to the 1275 block. I was expecting the machining costs to really hurt but I think I've gotten of lightly:

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

23rd Oct, 2014 at 06:45:45pm

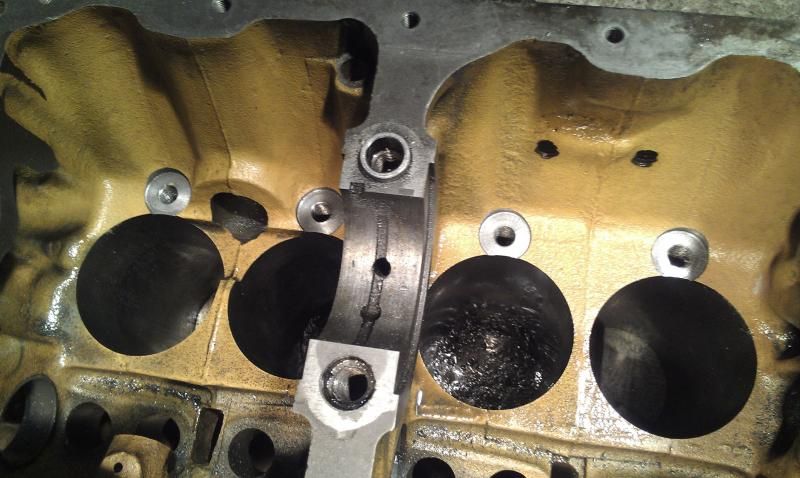

This week, my engine work has really bottomed out. I've put effort and money into getting my 1275 block up and running, only to find the mains are a mess and it will probably need another £200 to line bore them back into shape.

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

23rd Oct, 2014 at 07:30:29pm

This is a 12G940 head I had tucked away and just found it recently. It hasn't been skimmed and looking at the valve seats, despite all the crud, it looks to be in really good shape. The plan is:

|

||||||

270 Posts Member #: 69 Senior Member Coventry |

23rd Oct, 2014 at 09:48:23pm

interesting read some wicked ingenuity, be interesting to see what you could do with some decent gear.. |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

24th Oct, 2014 at 09:09:37pm

Yeah, I've gotten quite good at getting by with what every hand tools / power tools I have. A couple of months ago, I wanted to buy a bench grinder and realised that I don't even have a bench! Soon fixed with a bit of welding, and soon as it was done I wondered how I've managed for the last 15 years. One day, when I have my own double garage, I'd love some serious kit like a lathe and milling machine but that's a long way off.

|

||||||

6748 Posts Member #: 828 Post Whore uranus |

6th Nov, 2014 at 09:30:36pm

incredible inventiveness...makes me hang my head in shame at how little i get done. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

3rd Feb, 2015 at 11:20:37pm

Haha, only just seen your post Robert... If you don't think you get much done then check out the time-stamps on my posts!

Edited by PhilR on 4th Feb, 2015. |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

3rd Feb, 2015 at 11:29:48pm

Block next. This a 99p eBay engine and gearbox that looks to be in pretty good heath. Just need the block for now, so I'll crack on with a few modifications, 11 bolt, oil jets next.

|

||||||

|

95 Posts Member #: 10924 Advanced Member Wroclaw/Poland |

3rd Feb, 2015 at 11:42:39pm

Great job on the head.

Made in Poland build thread:

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

4th Feb, 2015 at 11:15:34am

Excellent work. Well Impreseed with the homemade stuff. Edited by theoneeyedlizard on 4th Feb, 2015. In the 13's at last!.. Just |

||||||

2094 Posts Member #: 9894 Post Whore Dorking |

4th Feb, 2015 at 11:30:14am

Awesome stuff! |

||||||

263 Posts Member #: 8923 Senior Member North Wales |

4th Feb, 2015 at 04:04:23pm

Great work phil |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

4th Feb, 2015 at 10:53:54pm

Cheers Guys.

Edited by PhilR on 4th Feb, 2015. |

||||||

144 Posts Member #: 10828 Advanced Member Rainhill, Merseyside. |

5th Feb, 2015 at 02:06:23am

Good work! Can't wait to see how the SPI system works, compared to a HIF44 carb. On 18th Nov, 2014 D4VE said:

went down to my local hydraulics place and he gave me a suitable replacement larger nipple  |

||||||

263 Posts Member #: 8923 Senior Member North Wales |

5th Feb, 2015 at 09:06:14am

What oil jets are thay?

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

5th Feb, 2015 at 10:28:35am

I can't believe that managed to cut the block. In the 13's at last!.. Just |

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

5th Feb, 2015 at 11:02:02pm

Turbo is a Chinese Edited by PhilR on 5th Feb, 2016. |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

6th Feb, 2015 at 02:09:56am

This is a cool thread; full of "can do" stuff. Never did I think a spade drill for wood, would ever work on CI.

On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

1750 Posts Member #: 10190 Post Whore belgium |

6th Feb, 2015 at 11:46:39am

Cool tread. You give me courage again for my turbo engine. you can do anything if you set your mind to it...

|

||||||

| Home > Show Us Yours! > Turbo Cooper - floor repairs | |||||||

|

|||||||

| Page: |

What turbo are you using?

What turbo are you using?