| Page: |

| Home > General Chat > clutch biting point | |||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

18th Jun, 2018 at 08:32:16am

I'd agree with that, shoe choice can be critical, gayboy loafers are definatly out.... I did find my knee would ache after a stinty in traffic, but that may be more down to my knees...

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

18th Jun, 2018 at 09:28:02am

The key, as TD says, is the MASTER cylinder pushrod.

Edited by Rod S on 18th Jun, 2018. Schrödinger's cat - so which one am I ??? |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

18th Jun, 2018 at 01:37:23pm

On 18th Jun, 2018 Rod S said:

Graham T did the same mod (we bought the parts at the same time) and I've felt his clutch since and it's lighter than a grey. I really wish I'd have done a force test on my pedal force before pulling out my grey so I'd have had data to back it up, but my peak pedal force is notably higher - not really identifiable from my leg but from my foot ache as mentioned. I've had a grey for years, and never felt discomfort like this. I guess engineering principles simply states that work is work. A spring with a higher clamping force will still ultimately require more "work" to release it will it not? As you mention - playing with lengthening the clutch arm length will reduce the effort, but at the sacrifice of travel - but it's the same"work" ultimately. The simple belville spring of the pre-verto is about as simple as it can get - the diaphram fingers of the verto definitely flex and "waste" applied travel (most notably on a new clutch when the spring is closest to flat), but that probably is partially offset by the very high forces on the arm pivot and clevis. One thing is for sure - there is a massive variation in characteristics of the Verto clutches, seemingly amplified when we stack the springs. I recall someone (evo perhaps) sayin they'd built three and every one of them felt different? Maybe I imagined that though lol - getting old!!! Certainly the one in mine is less progressive than the pre-verto, as I'm letting put the clutch, it seems to bite very quickly - probably because the force greatly increases pushing my foot up fast at that point. I had drag-strip starts on the pre-verto dialed in perfectly that I fed the clutch in easily with lots of revs and boost, giving a hard launch with minimal wheel spin (but would abuse the clutch plate but who cares lol). Given how the clutch feels now (or at least before I lengthened the master pushrod, but i don't think it'll change this), I'll not be able to adopt this launch strategy. I do need to address the wierd offset of my clutch pivot points I mentioned, but I don't forsee a significant change to the pedal characteristics. Edited by TurboDave16V on 18th Jun, 2018. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

18th Jun, 2018 at 03:29:45pm

Thanks for the pointers guys.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

18th Jun, 2018 at 03:50:08pm

"work" is work if you measure it in Joules to change the spring(s) from their least loaded case (clutch engaged) to their highest loaded state (clutch dis-engaged by your foot) but it's still force X distance for the load and it's the force on your left foot we want to reduce.

Schrödinger's cat - so which one am I ??? |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

18th Jun, 2018 at 04:36:58pm

When will you get it in Rod? On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

18th Jun, 2018 at 08:59:20pm

Here's a thought.

On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

19th Jun, 2018 at 01:59:54am

I just measured my plunger travel: 7.48mm

On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

608 Posts Member #: 1106 Post Whore Hungerford, Berks |

19th Jun, 2018 at 09:14:15am

Here is the information I gather back when I extended my master cylinder push rod.

’77 Clubman build thread

|

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

19th Jun, 2018 at 01:01:50pm

Wow, so I needed 7.48mm plunger travel to your 4.85mm.

On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

19th Jun, 2018 at 04:06:28pm

On 19th Jun, 2018 TurboDave16V said:

This variation is crazy. Yep, I remember back in 2016 when Graham and I were going through this, the measurements he actual ended up with were "similar", but not the same as, the initial measurements I did on a spare pedal box and master/slave that started our series of emails about it. As Colin says, maybe subtle changes over the years to make things better - or more likely to make it more warranty proof..... On 18th Jun, 2018 TurboDave16V said:

When will you get it in Rod? Usual "too many projects" syndrome but because I have a flip/removable front I could swap it before the planned engine out job if time allows between the decking I promised 4 years ago, the Cossie restoration, and so the list goes on.... On the pressure/work/load issue, what I do have is a pressure sensor on the clutch hydraulics. I installed it for the launch control / flat shift in MS2 as a more reliable way of sensing clutch engagement than a microswitch on the pedal that would require adjusting all the time as the clutch wore (at least on the pre-verto grey but still to some extent on the RTS as spring load still alters slightly with wear). It's not properly calibrated (no need to, just pick an ADC count from the 0-5V in the software that works) but would be a very good comparison of pedal effort between all the setups. I put a basic bourdon gauge on first to choose the sensor range and I think it was about 400psi line pressure on the grey to release (Sorry, I couldn't get a proper gauge in proper units for the initial test so had to resort lo last millennium units.....) Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

19th Jun, 2018 at 04:39:28pm

I'm getting close on 8mm plunger travel. I can't get it in gear with the engine running but I can spin the engine with the starter whilst in gear and clutch depressed, so it's nearly there.

Edited by Paul S on 19th Jun, 2018. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

19th Jun, 2018 at 05:04:24pm

OK, let's throw another one into the mix....

Edited by Rod S on 19th Jun, 2018. Schrödinger's cat - so which one am I ??? |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

19th Jun, 2018 at 08:20:35pm

On 19th Jun, 2018 Paul S said:

I'm getting close on 8mm plunger travel. I can't get it in gear with the engine running but I can spin the engine with the starter whilst in gear and clutch depressed, so it's nearly there. Ahhhh, well maybe you're at the point I was when I first tried my clutch - it wouldn't even attempt to disengage, even though there was (what i thought was) plenty of travel at the plunger. If your clutch spring(s) is too flat (in an attempt to maximum clamp load) then the fingers simply don't have enough stiffness to disengage the clutch with the available travel - they deflect, wasting the travel that should have been used to pull the spring off the backplate. It annoyed me greatly as I did so much measuring, accurate machining, lots of tests, comparisons, etc - but the one thing I didn't check before putting the clutch in, was applying a pre-determined distance of plunger travel to the "top hat" and verified it had lots of disengagement. I had force/deflection for the load applied to the top-hat, but never checked it against what travel I actually would see when installed and verify it was adequately released. I ended up putting some 33 thou die shims between the six bolts on the flywheel drive plate and the billet steel flywheel, which had the effect of "un-flattening" the clutch (like a part-worn clutch disc) and it then worked. The die shims are all surface ground to exacting thicknesses, so balance was un-affected. Edited by TurboDave16V on 19th Jun, 2018. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

19th Jun, 2018 at 09:12:08pm

On 19th Jun, 2018 Rod S said:

OK, let's throw another one into the mix.... How wavy are your wavy spring bits in between the two friction surfaces ??? I'm sure we've discussed this before but they all vary and I think I even posted photos of mine some time back. The 190mm performance plate (un-available back in 2016 for quite some time) doesn't need much to clamp it up. Some standard plates I've seen need a lot more, hence a lot more plunger travel to release. Graham and I both have the same 190mm plate because we bought the last few available at the time. EDIT - and let's throw a few more variables in...... How many people drill out the rivets and tap M8 compared to using bolts/Allen screws/nuts, I've seen so many variations on the main steel plate. How many alter the rivets on the drive straps to either bolts or to add extra drive straps, how many alter the recesses where the outer bolts go, and so the list goes on. The pair of springs may be the main difference in terms of release force but it's certainly not the only difference on how people have built these things since Robert's initial idea. Another variable - there are definitely two "backplates" (the part attached to the flywheel disc with the three riveted straps and the six raised lugs) of the AP style. PaulS's pic above, is one where you have (from the tip that touches the spring) a very large chamfer on one side, and a tiny chamfer on the other side. The other version has the "spring contact point" on a smaller diameter; recognisable by the two chamfers being closer to the same size (but the inner one is still a little larger than the outer). Also, I noticed that the height of the "spacers" on the standard clutch vary (but all within the same clutch are the same obviously) - I assumed the difference was to account for the different thicknesses of the spring, but the difference between them was not the same as the difference between the spring thickness, but I failed to write down what they were in my notes - and I pitched them so I wouldn't get them mixed up. Personally, I did this: Drilled and tapped the main drive disc 5/16-24, and drilled the thin stamped disc 5/16 thru. Turned new spacers 11mm OD. Height of the spacers was the original height for the flywheel assy spacer that came out, plus the thickness of the spring I added to the same assembly. Trial fitted clutch springs such that the tips of the fingers contacted - when bolted together in one orientation, the tips of the fingers were not contacting, so i flipped them. Completely standard drive straps and standard rivets. Lightened Billet flywheel from Minispares AP 180mm race rally plate. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

19th Jun, 2018 at 09:43:00pm

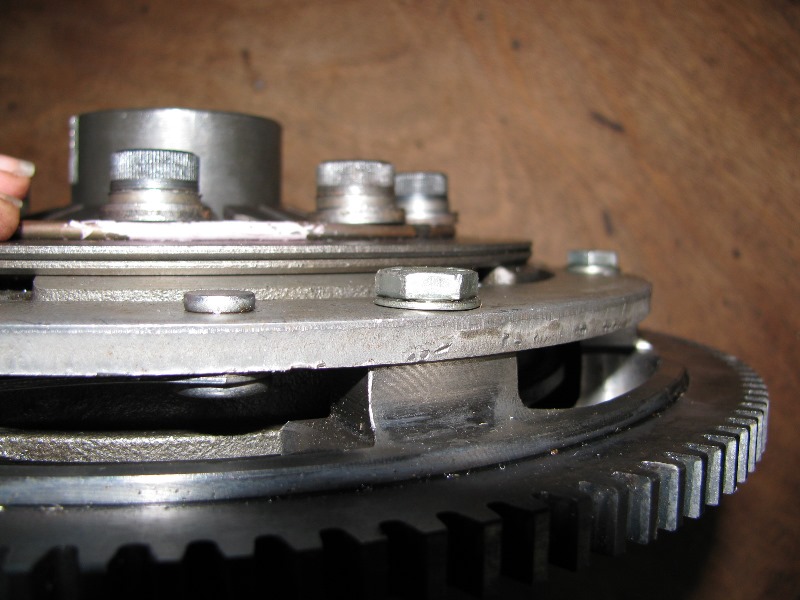

Here's the first one I built for the 1293 with 2 No. 1275 springs:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

19th Jun, 2018 at 10:33:14pm

Yep, that is flat for sure! It’s also the Valeo clutch.

On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

20th Jun, 2018 at 08:41:38am

I think that the major variables are the springs thickness, initial compression and overall condition and the thickness of the driven plate.

Edited by Paul S on 20th Jun, 2018. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

20th Jun, 2018 at 09:56:18am

I think what we really need is a replacement single spring to transplant into the verto, or preferably coming prebuild into a nice pressure plate assy ... On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

20th Jun, 2018 at 08:10:15pm

from memory guys the longer plunger and new clevis pins ( pedal box and wok) sorted it out for me Yes i moved to the darkside |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

30th May, 2019 at 03:57:49pm

A year on and I've finally found time to try and fix this clutch.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

31st May, 2019 at 10:07:24am

On 30th May, 2019 Paul S said:

Bought an extended rod for a Tilton master. Thanks Rod S for the link above. Cut and welded the clevis end on to the new rod. Just to update the link Paul mentioned, it's now this, https://www.competitionsupplies.com/tilton-...linder-pushrods Although you can probably get them from other suppliers too once you know the part numbers. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

2nd Jun, 2019 at 02:30:11pm

Bugger, still no gears :(

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

16th Jun, 2019 at 03:08:19pm

Sorted.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

17th Jun, 2019 at 06:15:42am

On 16th Jun, 2019 Paul S said:

Plenty of disengagement with normal 1/4" plunger travel. Add that to the puzzle :) I don't see why there shouldn't be. Apart from any difference in the way two springs flex when on top of each other, the amount the spring(s) need to move to disengage won't have fundamentally changed. The purpose of the further modifications Graham and I came up with was to be able to change the length of the verto release arm to increase the leverage (to make the pedal lighter). But as soon as you lengthen the release arm to make the pedal lighter it reduces the amount the release bearing plunger travels unless you compensate my making the master cylinder stroke longer. So the aim was to keep the standard release bearing travel but with a longer (and hence lighter) pedal travel. Schrödinger's cat - so which one am I ??? |

||||||

| Home > General Chat > clutch biting point | |||||||

|

|||||||

| Page: |