| Page: |

| Home > Non-Mini Discussion > New project -but not a mini | |||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

24th Feb, 2012 at 06:14:35pm

Got that bit sorted

|

||||||

720 Posts Member #: 2588 Post Whore Pretoria South Africa |

25th Feb, 2012 at 10:42:46am

Dave, it looks great !

"So wat we gonna do tonight Brain?"

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

25th Feb, 2012 at 01:14:19pm

The replacement steel (lots of it !) are a mixture of commercially avialable repair sections and some I have made myself.

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

6th Mar, 2012 at 11:54:10am

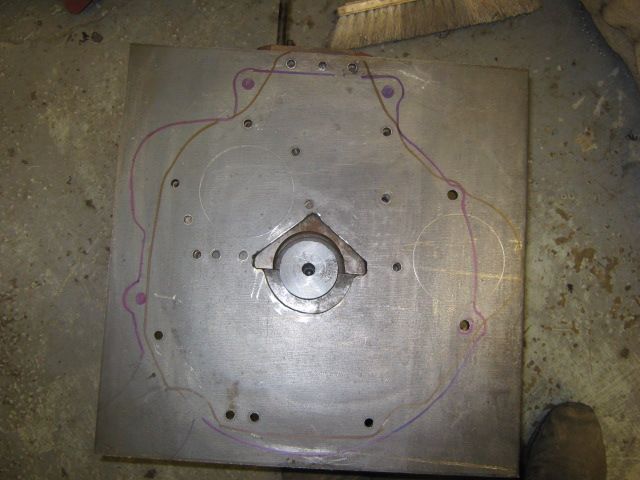

Got a bit fed up with welding and grinding so I have had a go at the new backplate to fit the BMW gearbox.

|

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

6th Mar, 2012 at 12:09:50pm

I would freehand gas cut that out, the shape will be only as good as the guy with the torch, but it should get it close enough to then finish with a grinder.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

6th Mar, 2012 at 12:10:55pm

Time.to join matty's chain drilling club On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

6549 Posts Member #: 1149 #1 Basshunter Fan Force Racing ICT Dept Manager Miglia Turbo Am frum Yokshyer tha noes! |

6th Mar, 2012 at 02:43:39pm

Loving the gearbox idea...

1/4 Mile 14.3secs 96Mph Terminal 10psi of boost.

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

7th Mar, 2012 at 09:13:29am

You say clever - some might say foolhardy and impetuous amateur. |

||||||

6745 Posts Member #: 828 Post Whore uranus |

7th Mar, 2012 at 05:05:49pm

plasma Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

7th Mar, 2012 at 07:08:42pm

Where, Robert ? |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

7th Mar, 2012 at 09:17:09pm

Bucks welding have a plasma Dave.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

14th Mar, 2012 at 08:11:59pm

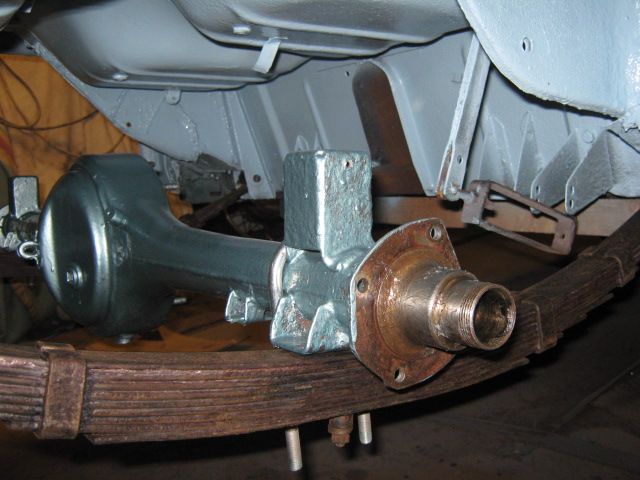

Well, I got bored with machining and drilling and my brain hurts with all this thinking about gearbox conversions so I went back to nice simple things like cutting, grinding and welding.

|

||||||

|

4018 Posts Member #: 1757 Back to Fucking Tool status Swindon |

14th Mar, 2012 at 09:56:23pm

Surely enough room to splice a honda crv rear end in there for a floating diff and non leaf suspension? Prob weigh less too Drives

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

14th Mar, 2012 at 10:48:43pm

Depends on how much it is necessary to shorten everything to get it inside the arches - I,m not flaring them !!

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

14th Mar, 2012 at 11:09:22pm

Nice work Dave. Was that all painted up when I last saw it? https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

22nd Apr, 2012 at 05:16:56am

Been avoiding the workshop for a while (new grand daughter, natural indolence)

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

22nd Apr, 2012 at 06:43:09am

just do it david , after all ,its a hosepipe ban , not a pressure washer ban Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

22nd Apr, 2012 at 08:09:08am

Exactly a pressure washer isn't a hose pipe. :)

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

23rd Apr, 2012 at 01:13:39pm

Today I was able to use, for the first time, one of the tools that Richard sold to me.

|

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

24th Apr, 2012 at 08:09:28am

looking good |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

24th Apr, 2012 at 07:45:18pm

Looking good Dave.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

24th Apr, 2012 at 08:20:42pm

I had one once but could not get on with it and TBH, I really needed one about 3 months ago for the sills and inner sills.

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

24th Apr, 2012 at 08:51:07pm

It was seeing how many welds you had to grind down made me think of it.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

25th Apr, 2012 at 01:42:04am

I kept having to set/reset the "burn time" as I seemed to either get no penetration or burn through. I also had to keep re-profiling the electrodes every time it burned through and steel stuck to the tips.

|

||||||

7763 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

25th Apr, 2012 at 07:46:38am

What a fantastic project. Is it hard getting body panels for it? On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

| Home > Non-Mini Discussion > New project -but not a mini | |||||||

|

|||||||

| Page: |