|

Home > Show Us Yours! > Josh's turbo 1098cc carburetion sucks lets try EFI

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

rob, should be moveing home to geelong,batsford next year to be with the famaly thats is there is anychance of a job there given the current closures of ford holden alcoa shell bla bla state seams to be dieing

anyway

yep had them crack test the rods and crank before doing anything ive got 3 dead 1098 cranks

yes the cam bearings are the ones you more or less belt in with the proper tool to keep them going straight

should the cam turn with a bit of restance or should i beable to sort of flick it and it free wheel? at the moment it free wheels if only pushed in about half way but when centered up in the bearings its got a bit of restance to it ive herd in this situwation you can install the cam compleatly dry and gently turn it over by hand this should polish the high spot witch can then be one way or another removed ?

ill try some 1200 wet n dry with a steal rod about the bearing size for a backing to hopefully take only the high spot off with out deforming the bearing?

id like to take my stuff to a shop and have it checked out but how the hell dose one know it will be done right! once bitten twice shy! ha

checked the cam timing and ive got it at 3 degrease advance atm witch is 109 full lift center line the cam sheet calls for 112 center line full lift at TDC so i had a mess around seams thats the best i can get? i will keep trying to get it bang on tho!

do you think it would hurt the top end (6k limit) on a boosted set up being 3 crank (1.5cam) degrease advance? i know that it should give a bit more low rpm torque being like this?

it seams the intake events are not where kent cams spec sheet says they should be but the full lift is well 3 degrease off but the valve open and close points are much further out?

the exhaust events are spot on tho? valve open and closure to the degree ? haha i dont know keep trying i think gota get it soner or later

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

well ive gotten the cam in with in a half degree.. 111.5 lobe center line @ full lift

the method ive used is

found true tdc useing a bump stop, turning till it hit note reading turn other way till hit add together divide two move disk to number then checked it the same way with both number being the same.

then ive set the crank to the 112 degrease at witch full lift should be along with turning the cam to full lift or there abouts

chosen key ways that allow the gears and chain to go on with out moveing the crank or cam

checked the center line by turning in the running direction till full lift then zeroed the gauge keeped turning in the runing direction till 1mm before full lift note crank angle then rotated in running direction till 1mm after full lift note reading add them devide two thats what im calling the center line angle

think this is the correct way to check crank cam relation ship?

also center punched the key ways so i know witch ones to use haha

Edited by Turbo This.. on 15th Feb, 2014.

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

any ideas for seeing where the oil cooling jets actually spray?

sort of thinking i might try rig up some kind of electric pump into the main galley with kerosene or something?

id have to find a way to plug a lot of oil passages tho.. or build the whole thing up and gravity feed the oil pump turning the engine over by hand with out rings perhaps making a bit of pressure to see where they shoot at

im now happy with the cam timing and will look at sorting the cam sensor position witch ive planed out

as the local shop wants like 70 bucks for the m10x1 tap im going to get a nut and weld that in place instead

as for the cam sensor ill do the same but with a set of riser tubes and angle plate kinder like meds kit but made in steel and much cheaper with a different sensor

need to order the blanking plates for fuel pump, dissy and a heater take off

cheecked the ring gaps and they are not all the same the top rings are up to 6 tho diffrance n second rings are about 3 tho i checked them all in number one bore at the same depth set in nice n square so confdent they are good mesuments

thinking i might get a ring filer and at least make them the same ive left the numbers in the shead other wise id wite them up

|

Rod S

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli)

5988 Posts

Member #: 2024

Formally Retired

Rural Suffolk

|

|

On 16th Feb, 2014 Turbo This.. said:

or build the whole thing up and gravity feed the oil pump turning the engine over by hand with out rings perhaps making a bit of pressure to see where they shoot at I doubt you would get enough flow to build up enough pressure to open the ball valves inside the jets. If you want to actually see oil (rather than just pointing the physical jet in a suitable direction) you're likely going to need to rig up a pump of similar flow/pressure as the real pump when it's running at speed.

On 16th Feb, 2014 Turbo This.. said:

as the local shop wants like 70 bucks for the m10x1 tap im going to get a nut and weld that in place instead

That is expensive.... a full set of three (taper, second and plug) is less than 1/3 of that over here and you probably only need a taper anyway, the others are for blind holes.

http://www.ebay.co.uk/itm/HSS-Tap-Set-M10-...=item417c6d383f

Schrödinger's cat - so which one am I ???

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

i think your right as ive got an oil feed cam that will surely piss everywhere now i think about it..

think ill stand a chance if i can just pressure rise the main galley and block all other take offs/passages with something?

had a quick go at the plastigauge on the big ends and it didnt go so well haha how do you hold the crank and rod so they dont move? when i had a go it moved and smeared..

ive got the blue and green ones think 1-3 and 4-12? or what ever it is i forgotten

|

Rod S

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli)

5988 Posts

Member #: 2024

Formally Retired

Rural Suffolk

|

|

On 17th Feb, 2014 Turbo This.. said:

.....how do you hold the crank and rod so they dont move?

Turn the crank to the best place for doing two of the rods, take off one of the main bearing caps and remove it's half shell then nip it back up with something softish, like a small bit of wood or even folded up cardboard, in place of the shell. Just something that will grip the main bearing journal but not mark it.

If the rings are on the pistons, the rod won't move when you take its cap of to gauge it, if the rings are off shove something up the bore from underneath (assuming the engine is upside down) to keep it held against the big end journal when you take its cap off.

Schrödinger's cat - so which one am I ???

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

right i have about 1.5-2 tho on the mains haven't yet looked at te book to see what it should be or what is normal for a boosted long stroke engine?

there seems to be a tiny bit of variation so may have some shit in there some place? ill have a second go tomorrow also do the rods then

got a bit carriyed away cleening things the crap just keeps comeing out going to order me a proper blush set now

ok vizard says to use bottom limit at so what ever the work shop book says in the most gap allowable and if its going to scream then up to 2 tho under bottom limit ! seems my crank is on the tight side!! perhaps a grind whould be goos to fix up the jurnals and get a better oil clearance? or fit 10 under shells?

Edited by Turbo This.. on 18th Feb, 2014.

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

right well finally got some time to get back on with this

i have platsi gauged and fully washed all parts twice and came out with the same results

all rods gauge at 1 tho really close and hard to pick a difference between rods they all look nice

the mains show a concistant 1.5-2 tho id guess to be 1.75 tho as they all looked identical and nether 1.5 or 2

i cheeked the workshop book i have and its in those ranges but is it advisable to run more oil clearance?

thrusts check out ok by the book too but what do people run with boosted engines? are the oil clearances bigger to account for the flex and what ever else? thinking im ok to run with these mesuments all be it plasti gauge..

also looking at using an efi pump to see where my oil jets really point will see to that tomorrow

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

going to use a propane tank filled with light oil and compressed air it will have a ball valve into a line connected to the block rather than a pump of sorts as it seems the engine requires a lot of volume rather than pressure as such pressure being restriction to flow so makes seance...

i have blocked the head feed and installed a non cross drilled cam vs the huge oil leak that the cross drilled cam is... did not realyse how much the x feed cams flow/leak there sure will be a lot of oil flying around the crank case! also it add to the need for oil feed into the center main as thats where the cam takes its oil for the cross drillings so perhaps its not a bad idear to slightly inlarge the center mani oil feed from the gally?

not sure seams there is a huge demand on the one oil feed as it has to do the center two rods the center main the cam feed both bearing and x drillings

where the other two drillings do one rod main cam and rockers

other doing rod and main thats all

just think it seems not really equal in the way it all flows and whats feed where not that much can be done to change it tho?

orded the M10x1 tap so can get on with the sensors cam crank sorted out where ill put them hopeing it works as expected..

got the replacment coil plug as i messed one up haha

running out of excuses as to not having this finished

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

ok i have been into see the shop with the parts im concerned about think things will work out ok and get sorted so pleased with that at this stage

have received the kind gift from Rod S thank you very much for the correct resistors to get my sensors working on the ms3x v 3.57

sorted out the oil jets and happy with them now since marked the jets for locations

used an LPG tank empty of course drilled n taped to get two ports one on top for compressed air line (60psi) nd one at lowest point for ball valve to let the oil out into an external oil filter into the block where it normally goes feeding the engine

with the engine all built up std cam installed as x drilled one leaks oil like mad heal feed blocked with gasket material and plate

at this stage i positioned the crank rods pistons where i pleased then open the ball valve letting a huge amount of 10 weight oil go everywhere! haha yep plenty of oil everywhere! well pleased and not so worried about melting pistons now but it is still a real fact that it could happen if not tuned correctly!

had to back n forth n tweak them to get em hitting the best place i could ended up being a sort of sweeping pattern due to the angles as the piston makes a cycle the stream moves back n forth under the crown along side the wrist pin the rod gets in the way and wets the bore up pretty good as well just hopping the oil rings cope haha

as im writeing this i think it whould have been real nice to video it to show n perhaps do a thread showing in regarding oil squirters for people intrested i may rig it all up when it comes back from the shop

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

latest n gratest delemer, puled the box apart yet again as im not happy with the way it was..

so seams ive got a taper on some thing be it the shaft, gears or both?

ive taken a vid to explain this better and im going to have the shop mic is it up see what the heck is going on..

so my best explnation is that first gear is good and what id expect the gear drops on nice with out any force under its own weight as id expect also spins and free wheels also as expected

how ever second and third as crap.. they are stiff to push on and once on you can turn them but they walk sidways then lock up also kinder stiff and dont free wheel so not happy to run it like this and hope for the best

whats your thoughts? will see what the shop finds on monday ill have them bore gauge the gears and mic the shaft of taper and size compareing mesuments with first gear as that seems to be good by feel anyway...

the parts are all new but have been sitting for like a year no clue where i bought them from now slim chance of sending them back depending on cost to fix this might buy new ones hope fully decent! ha

also some how ive buggerd up the coating where the syn ring grabs the gear its chiped the coating off its all below surfice as aposded to rased could thes be a problem? i think there is plenty of surfice left thinking ill run with it but if advised not to by the knowagble people ill just get a replacement..

also the parts are super clean and well lubed with clevite bearing gard the stuff recomended for the crank mains/bigends nice n thick and stick/stays put for a long time

also ive gotten the cam in bang on straight up at 112 and getting near enugh the advitised numbers for open close angles and lift values

drilled the hole and taped the cam gear installed the cap head that hopefully will tell the ecu what cylcle its on but ive screwed up and gotten the wrong tap for the backing plate haha dumb ass will be makeing the crank mounting thingy hopefully this week after work but will also need the M12x1 tap not the M10x1 ive got.. was all like shit ive drilled the hole to big! then was like nope wrong tap after i offred the sensor up haha o well supose its the better outcome

also the mono tourqe gasket ive used mesures 42 tho but not to sure as there seems to be a few tho diffrance depending on where i mesure this is probaly due to the block being dead flat but the head possibly bent? not sure i will re check this once the head has been done and is flat trying to run as much compression as i can to low end also to take advantage of the E85 fuel it like compression

short vid showing the box problem...

getting fed up with new part that are shit and dont fit or ant what they should be

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

right then not gotten far but had the gear set sorted was a combined stack of tolerances bit of taper and egg anyway its sorted now and runs true ive bought my self a set of micrometers, snap/telescoping gauges and dial bore gauges i plan to have a "play".. want to double check to the best of my ability before anything goes together for peace of mind also so when its pulled down next i can re measure and compare.

i have made a dam mess in the hopes of cleaning up the workspace prior to the build ended up chopping my work bench down and welding a bunch of shelving to get things set up properly also renewed the bench top and backing Bord with nice fresh clean stuff to avoid contamination at build time.

will be starting the dry build soon yeh ha!

edit: pic

oh yeah bought me a 72 panel van ill put the turbo engine in and put its 998 into the club bit of messing around but hey vans are cool

Edited by Turbo This.. on 29th Mar, 2014.

|

minimole23

4304 Posts

Member #: 1321

Post Whore

Wiltshire

|

|

Nice, could you have found anything bigger to get it delivered on?

On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding

|

Rob Gavin

6729 Posts

Member #: 618

Post Whore

Glasgow

|

|

Coming from the guy that turns up a mitp with a 20ft trailer!

On 29th Mar, 2014 minimole23 said:

Nice, could you have found anything bigger to get it delivered on?

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

haha yeah bit over kill but hey its who you know.. my clubby was delivered on a low loader used to carry big machinery have a pic of that some place had to take that pic from a distance to fit the whole truck trailer in the mini looked like a spare wheel on the back

ill see if i can find the picture

was raining all day so didnt do crap all except make me a white board from a 1200x1180 sheet of thick glass painted the back of it white and welded some angle iron to the container will do the job! just dont whack it as its tuffend glass and will go pop into a million bits!

|

minimole23

4304 Posts

Member #: 1321

Post Whore

Wiltshire

|

|

On 29th Mar, 2014 Rob Gavin said:

Coming from the guy that turns up a mitp with a 20ft trailer!

On 29th Mar, 2014 minimole23 said:

Nice, could you have found anything bigger to get it delivered on?

It was at least filled to capacity

On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

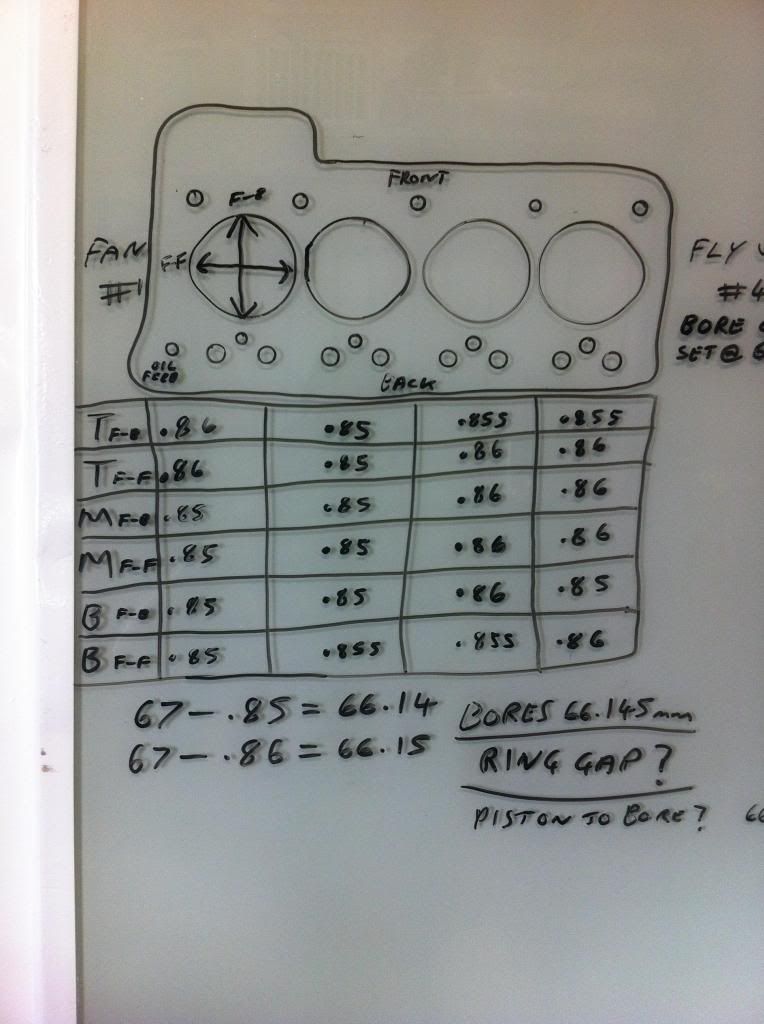

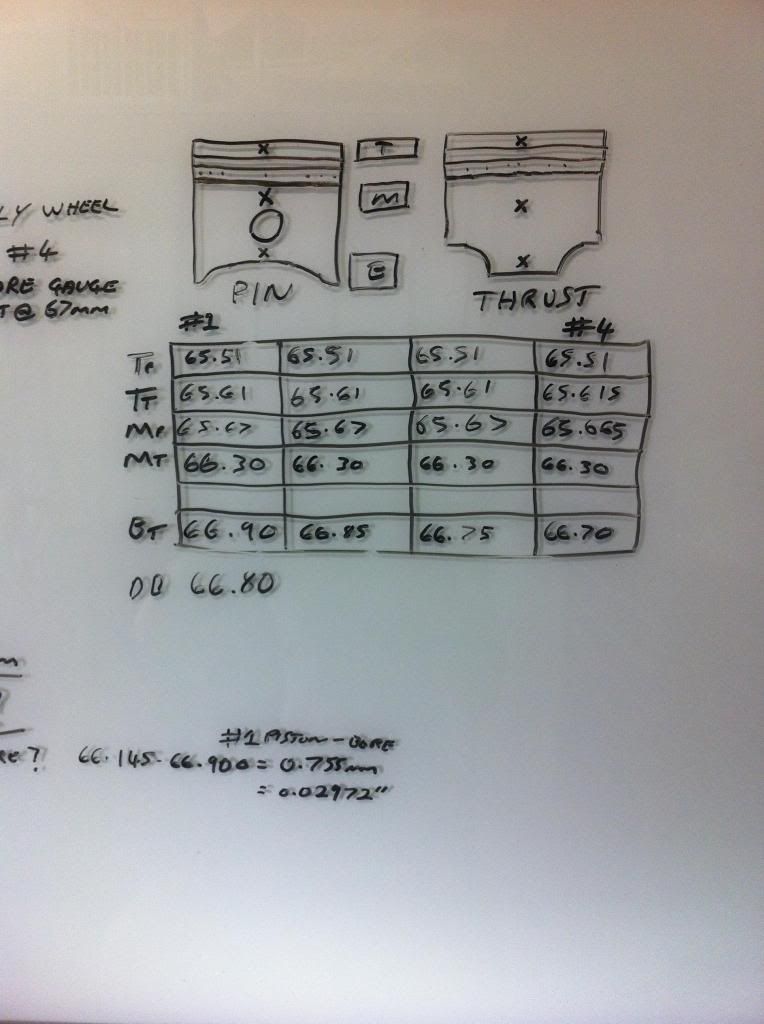

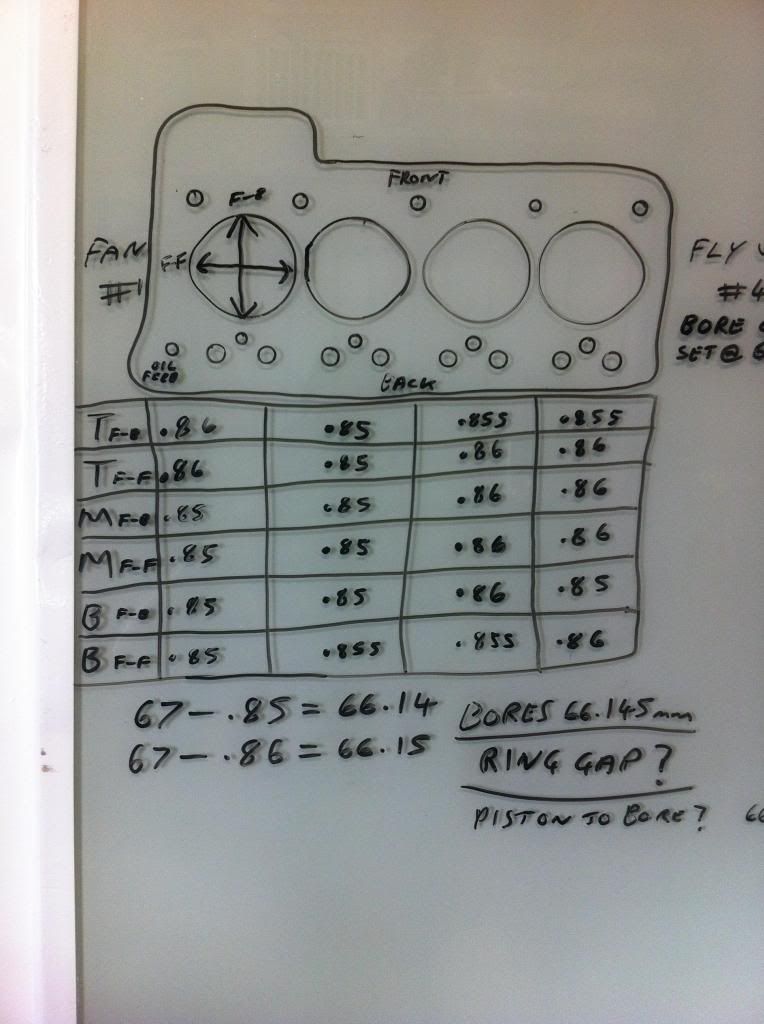

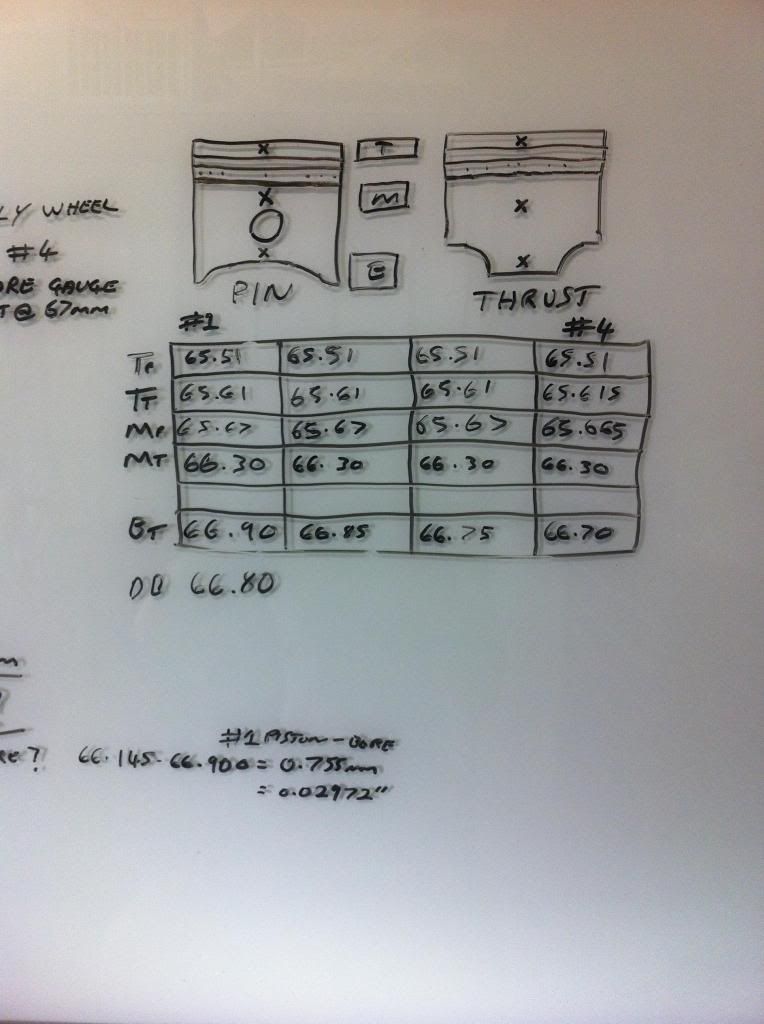

ive gotten the pistons and cylinders measured up and they seem to be correct to me taken at top (where rings are at TDC) mid way and bottom where the skirt will be BDC

largest difference is 0.01mm or 0.00039"

there is a little bit of difference in the fattest part i could find in the skirt thrust bit as you can see i did re check my measurements and they repeated themselves could this be anything to worry about?

rest of the pistons are bang on like for like

largest piston size has .755mm or .02972" piston to bore clearance ive lost my sheet that came with the ST flat tops 0.060" anyone know what clearance and the mesuremnt as to how far up the skirt im supost to mesure? rather than just finding the fattest place all be it the more or less the same distance up

my dial bore gauge wont fit in the main line or big ends so will get an aproaitle one asap

i just what to be sure that its all good and wont kill itself peace of mind also

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

right getting bored waiting for total seal to get back to me so looking for things to do

so bored ive thought for a second about modifications to speed up oil return to the sump like polishing the inside of the block and head to a shine

have thought about glyptal or what ever its called but have no way to bake it propaly so dont want to risk it lifting off and jamming the pump up

any reason not to paint the (outside) engine block and bits before assembly or better practice to make it looks nice all built up?

i think if i mask it all off well gasket faces and so on then there should be no problems aside from possibly marking it on assembly? or some bits being missed

it will be 2K paint and the block will be super clean

think if its all built up then painted it will seal up all the bere metal like arount bolts and such also there whont be paint under the bolts and things

it will look like a tractor engine thos you know how those guys like to paint everything lol

on the other hant engines look grate with the contrast of new fasteners and crisp edges gasket lines so on

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

Alright then been working away on the hayman island resort so not had a chance to do anything

but im now well motivated again due to the machine work problems sorted buy some grate guys at jack brothers cheers

so waiting on some fresh bearings as im not keen to use the current ones that are all marked and probably out of shape from the taper it had

anyways i should have the engine built up less the head shortly

ill be using the head from my van as a starting point as i believe its not modified in any way and being the 202 casting (heart shape chambers and tinny ports) its got the most meat to get the correct shapes its more work to get it done but you cant put metal back in there..

ill then do a freshened up head for the van out of the other heads ive got im just not happy to use the ones ive been playing with on the turbo much rather use one of them on the not so critical std 998 rather than the expensive turbo

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

what a ball ach this is non of the parts ive bought are right or the work ive had done is right

well crap all has happened since last post more of a to do list this

so ive managed to leave one of the banjo bolts for the oil jets in the work truck witch is 14 hours away.. i had grabed it as a sample to get copper wasshers lol the job was supost to be finished by now

oil jets cant go in so the short block cant be built up

still haveing a taper problem with the gear set i had the main shaft squared up and its spot on now but the gears 2 and 3 have 0.015mm or almost 6 tho over 22mm distance lol so im trying to find a lapping tool to make them cylindrical

i have built up the fromt subby with new wheel bearing seals re packed the bearings as they are still like new new tire rod and lower arm bushes re shimmed the ball joints also like new just a little lose so got them slightly tighter re greased the nuckles for the hilows new genuine mounts

got rid of the 1inch drums on the back for std ones with new shoes at this point i remberd i need short studs lol also rea wheel bearing seals so waiting on those parts to finish that

gonna run my 12x5 magnesium wheels just need some treads thinking the Yokohama road/wet slicks

13x6 are poo unless on a track road use is crap

waiting on my tax retun to buy my tigwelder then ill do a bunch of stuff ive been waiting on like air box, brackts, ic pipeing, coil brackes, trigger wheel pick up bracked bla bla

ream diff side covers as ive pressed new ones in

head work

paint engine bay

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

right a small update

got the box sorted bought a barrel lap and some dimand cutting compound to get the gear bores round and true worked a treat now the gears dont walk across the shaft and lock up! all built up and ready to rock got a reamer to sort the diff side covers as well i gave it a tho running clearance not sure what it should be i called mini spares and they said we just get the shop to sort it... i said can you ask them what they give it? the reply was in short no! wtf!

anyway can't rely on anyone!

some how ive lost on of the bmw oil jets spouts for fuck sake the only thing stopping me getting the block built up and on the box

will be tearing the workshop up to find it tomorrow and looking at what ill do for a cylender hear aswell im thinking of getting a russle head depending on price?

|

gr4h4m

4890 Posts

Member #: 1775

Post Whore

Chester

|

|

Good luck with the search!

I run a supercharger and I don't care the TB is on the wrong side.

VEMS + 12 PSI + Liquid Intercooler = Small Bore FUN!

|

gr4h4m

4890 Posts

Member #: 1775

Post Whore

Chester

|

|

Good luck with the search!

I run a supercharger and I don't care the TB is on the wrong side.

VEMS + 12 PSI + Liquid Intercooler = Small Bore FUN!

|

Earwax

109 Posts

Member #: 10368

Advanced Member

Australia

|

|

You aren't having much luck lately ....

I am glad some of the previous machine work is being rectified. I would still have grave concerns about the piston mods - anything sharp is going to create a hotspot

also that crank keyway is crucial to be 100% solid, this is the backbone of your build, did you work out what lift the cam was giving? Keep at it

|

Turbo This..

1767 Posts

Member #: 9165

Previously josh4444

Australia, brisbane

|

|

yeah me to mate the short block is now built

hot spots are a big thing for me in terms of "controlling" pre ignition the reason i polished the piston tops to a mirror finish the under side and oil jet relif mess that the shop did theres not much i can do really just tidyed the edjes and re ballanced them as a compleate piston ie pin rings pft butons to get equal weight anyways

the keyway looks worse than it is to be honest its nice and tight and also once the bolt is torqued up i really couldent see it moveing

i really need to sort the head ether buy one or do one myself as im not going to set the timeing till its on as i want to tweak each valve lash setting to get the thing spot on for each opening/claseing point russle talks about this on his website

still cant find that blody oil jet ive made a wanted add in the hopes someone has or can get/send me one for some cash as thats really all thats stopping me from getting the box bolted up

so the to list atm is get the jet sorted along with a head

once the timeing is done get the damper on and make the crank sndeder holder thing done

after than its basicly get it in the subby and under the car !!

|

|

Home > Show Us Yours! > Josh's turbo 1098cc carburetion sucks lets try EFI

|

|

|

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli)

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli)