| Page: |

| Home > Show Us Yours! > Josh's turbo 1098cc carburetion sucks lets try EFI | |||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

29th Oct, 2013 at 08:00:28am

Good to see it's working as expected now.

On 29th Oct, 2013 Turbo This.. said:

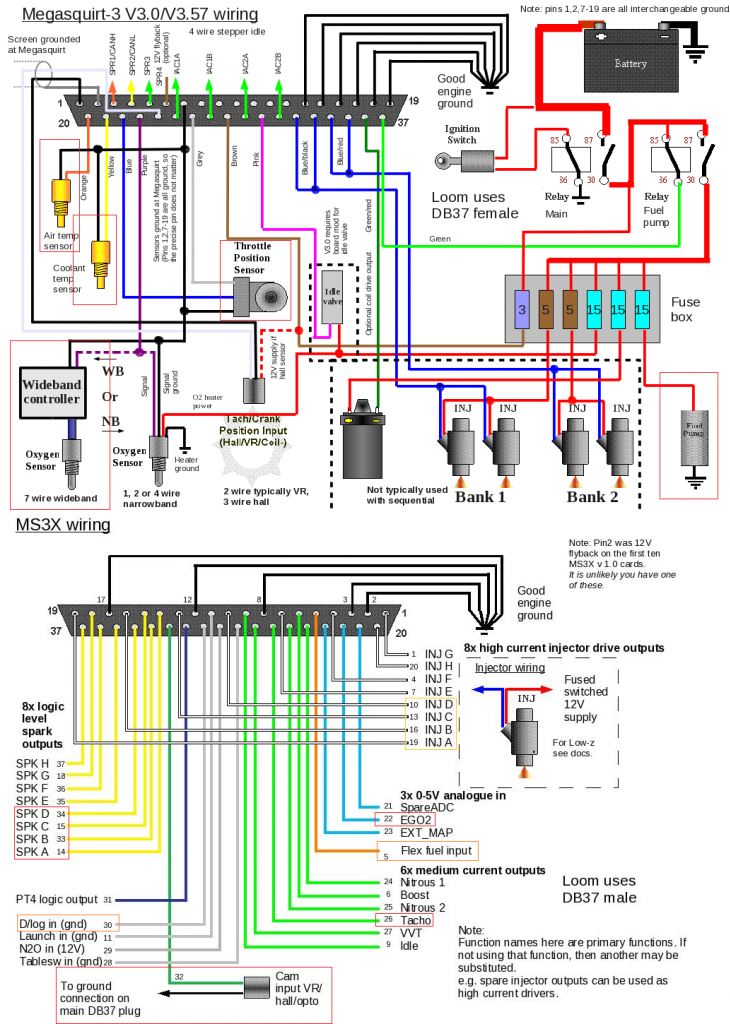

id not have thought id need to open the ms3x box at all thats kinder why id bought it in the first place... But you have to bear in mind the very concept of MS (whether 1,2,3, or 3X) is to cover hundreds of different possibilities. That's why those of us with V3.0 boards build them to our own requirements and why the V3.57 has loads of jumpers and solder pads to customise it. It sounds as if the way yours has been supplied is about right for your scenario (as it's responding to the JimStim) but I wouldn't be surprised if you had to adjust the pots as a minimum once it's connected to real sensors and wiring. And, as Paul says, if your Hall switches have the pull-ups built in that won't be a problem (the ones I use don't) as your current JimStim configuration is replicating the "built in" pull-up. Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

6th Nov, 2013 at 08:45:48am

well ive been bussy with work so dont have anything to add of grate intrest apart from getting my other inter-cooler parts like coolant pump hoses dump valve charge cooler claps fittings boost pipes bla bla...

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

15th Nov, 2013 at 08:34:58am

ok so while mocking up the coolant side on my inter cooler ive lent that dry tapered threads in aluminm and a brass barbed fitting is a BAD !!!! idea ive buggered up the threads in my inter cooler!

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

15th Nov, 2013 at 08:54:30am

Peak and valley width don't have to be identical.

Edited by Rod S on 15th Nov, 2013. Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

15th Nov, 2013 at 09:00:23am

cheers rod, im going to cut the missing tooth out when i make the bracket with the die grinder i think that should avoid messing that up i hope?

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

15th Nov, 2013 at 09:11:48am

ohh yeah i cant fit the air filter where i wanted to or any other place for that matter

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

15th Nov, 2013 at 09:41:21am

On 15th Nov, 2013 Turbo This.. said:

one more thing should i have it cut with a square end mill or a rounded one the google pic ive seen all have a sort of rounded shape in the gullys?? Not really important so long as the corners of the top edges are square (or as close to square as possible) ie, you don't want it to be a shallow slope into the gully, it want's to be a nice sharp corner at the top but below that, whether it is square or round doesn't really matter. Square is (marginally) better for the Hall switch but rounded corners in the valleys is much better from a stress raiser point of view especially if you are cutting that part of the pully/damper quite thin. Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

15th Nov, 2013 at 10:29:35am

ok i think ill go for a half way effort of a flat base and a radius into the walls should be good at that also will retain a touch more mass in the ring witch is a good thing all depends on what tooling the shop has i guess.. |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

18th Nov, 2013 at 07:26:35am

well today has been disappointing!

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

22nd Nov, 2013 at 09:39:56am

right the new loom has made it into the car so far its just split into rough bundles that most probably will be the branches once loomed up

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

8th Dec, 2013 at 11:19:26am

ok so been busy lately but now have some time to play.

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

8th Dec, 2013 at 02:20:25pm

On 8th Dec, 2013 Turbo This.. said:

so i was looking up the pin numbers and what ill need to each plug anyway the coil spec says a max current of 19 amps ? since ive got 4 thats 76A if they are full tilt.. that seems a lot! also seem unrealistic? Which one(s) did you choose in the end - I remember some discussion but can't find the correct part of the thread. Firstly the maximum quoted will be at extreme charge/dwell times (nowhere near where you should be running). Second, it's an instantaneous value (a few milliseconds) so the cable won't melt or the fuse blow in a few milliseconds unless they are seriously undersized. Thirdly, they don't all charge/fire at once, they are all operating totally apart from each other so no need to multiply by 4. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

8th Dec, 2013 at 04:33:37pm

I've ran wasted spark and 4 CNPs on a 15 amp fuse. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

8th Dec, 2013 at 05:49:07pm

use Ohm's Law to determine a rough full current draw of each coil. The coil would never ever survive at that, but it will give you a good idea what the max current would likely be for the coils you have. Use a smaller fuse rating than that to protect the coil from a constant power situation.

On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

8th Dec, 2013 at 09:36:39pm

ive got the expensive ones i dont really need them but hey...

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Dec, 2013 at 09:11:09am

I don't think you can halve the fuse rating by splitting the load. It does not work like that. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

9th Dec, 2013 at 11:02:34am

As Paul says, it doesn't quite work that way.....

Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

10th Dec, 2013 at 09:50:13am

well i think i understand? haha |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

10th Dec, 2013 at 10:44:44am

On 10th Dec, 2013 Turbo This.. said:

im a correct to think if they are in pairs i can use two 7A-10A and if they are all together use a 15A? NO !!! Unless you use exessively long dwell (charge) times or extremely high RPMs, it doesn't matter whether you use one fuse for all four, two fuses for pairs, or four fuses for them individually (see note below). They all charge at completely different times so the fuse(s) have to be good enough to supply (and protect the wiring of) any individual one when it is charging. So whatever rating you chose will apply to a single circuit, two circuits or even four circuits. The current figure I suggested is an estimate based on what DIYautotune say for that particular coil (slightly higher than an LSx) and the known characteristics of my old skool coilpack. a 15A fuse gives a sensible margin over that to avoid it blowing un-intentionally. 10A would probably do. Just make sure the wiring, whether one, two or four circuits is rated higher than the fuse. On 10th Dec, 2013 Turbo This.. said:

possibly pair up cylinders that are charging 180 degrease apart? As the only reason I can think of to want to wire them as pairs is to let two keep running if a fuse blows, I'd put them in 360 degree pairs (an engine cycle is 720 degrees). That way the engine "might" run on two cylinders. But I would never run like that anyway, not even to get home - no spark means fuel washing all the oil off the cylinder bores. I can't really help on the MS3/MS3X input/output stuff as I use MS2 with an IOx. EDIT, added this just for clarity.... If you were to risk an 1100cc A series at 8000 RPM, the engine cycle time is 15mS (obviously its way more than 15mS at sensible RPMs) Thus individual COPs at 8K RPM would have 3.75mS available to charge without their current draw overlapping. The DIYautotune spec says nominal 3mS required for these coils so plenty of margin against them drawing current at the same time. Even if you did want to go higher (RPM or dwell) and risk the coils overheating, the charge current is exponential, starts low and rises, so even if you did exceed 3.75mS dwell and/or 8K RPM, you would not be doubling the current, just adding a little bit to it as one finishes charging and the next one starts. Edited by Rod S on 10th Dec, 2013. Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

10th Dec, 2013 at 11:23:56am

thanks rod for clearing that up lol

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

11th Jan, 2014 at 03:48:25am

not much happening lately but ive been messing with the wiring atm witch leads me to my question and the point of this post

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

12th Jan, 2014 at 08:49:25am

For the sake of a few extra pence (cents for you) I would use it.

Edited by Rod S on 12th Jan, 2014. Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

12th Jan, 2014 at 11:46:34am

sounds like ill just use shielded stuff to be safe and hassle free

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

12th Jan, 2014 at 12:18:27pm

On 12th Jan, 2014 Turbo This.. said:

sounds like ill just use shielded stuff to be safe and hassle free what sensor are you using if u dont mind? ive not thought to much about the wheel movement have you taken a route similar to the brake line? Pictures of my sensors (rear install only so far) part way down here http://www.turbominis.co.uk/forums/index.php?p=vt&tid=541462 Not really off the shelf stuff I'm afraid but ideal for what I want. No cable pictures taken but, yes, similar to brake line at the rear. The fronts are going to be (not yet fitted) on the inner pot joints so flexibility is less of an issue. On 12th Jan, 2014 Turbo This.. said:

is there a way i can get my crank n cam sensors to give ms there signals while ive got the dummy engine in the car? short of making some kind of convoluted contraption haha perhaps using the stim? The JimStim simply replicates the crank/cam (and other) signals to prove the MS3 itself works as expected so is of little use in the car. If you just want to prove your crank/cam sensors work correctly with a "dummy" engine (whether in the car or not) just power up the MS3 with injector, fuel pump, and coilpack (or CNP) fuses REMOVED, just the MS3 power fuse installed, and spark plugs out, and spin the engine on the starter motor. Then use the composite logger in TunerStudio to check you are getting the 36:1 signal (once every revolution) and the cam signal (once every alternate revolution). This will be a good check that the cam signal is in the right place relative to crank missing tooth. Schrödinger's cat - so which one am I ??? |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

14th Jan, 2014 at 09:33:16am

rod do i need to have that Manny signals per rev?

|

||||||

| Home > Show Us Yours! > Josh's turbo 1098cc carburetion sucks lets try EFI | |||||||

|

|||||||

| Page: |