| Page: |

| Home > Show Us Yours! > astra 1.4 8valve lpg turbo. | |||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

24th Jun, 2014 at 08:50:26am

On 24th Jun, 2014 robert said:

unless they are saying.... closing ms is a time when its still flowing gas until injector is closed ,,so its still flowing for that time AFTER the pulse has ended .so that has to be taken off the opening time that delays flow after the pulse starts for the opening time ms. does that make any sort of sense ? How long are your calculated pulse widths? For example, if you need only 2mS, then only adding 1mS for opening and closing, giving a total pulse of 3mS is not going to actually open the injector fully. It's an exaggeration maybe but could be the cause of the issue at greater pulse widths. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

6752 Posts Member #: 828 Post Whore uranus |

24th Jun, 2014 at 09:53:06am

hi paul, thanks for chiming in ,

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

24th Jun, 2014 at 10:36:00am

I would start by getting the REQ_FUEL right. It is used for calcs other than just the main pulse widths, so best get it right and stick with it.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

24th Jun, 2014 at 10:40:09am

From what I've seen on Jean's forum - where people have been experimenting with P&H drivers for LPG - the LPG injectors are horribly slow.

Edited by Rod S on 24th Jun, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

24th Jun, 2014 at 11:07:24am

On 24th Jun, 2014 Rod S said:

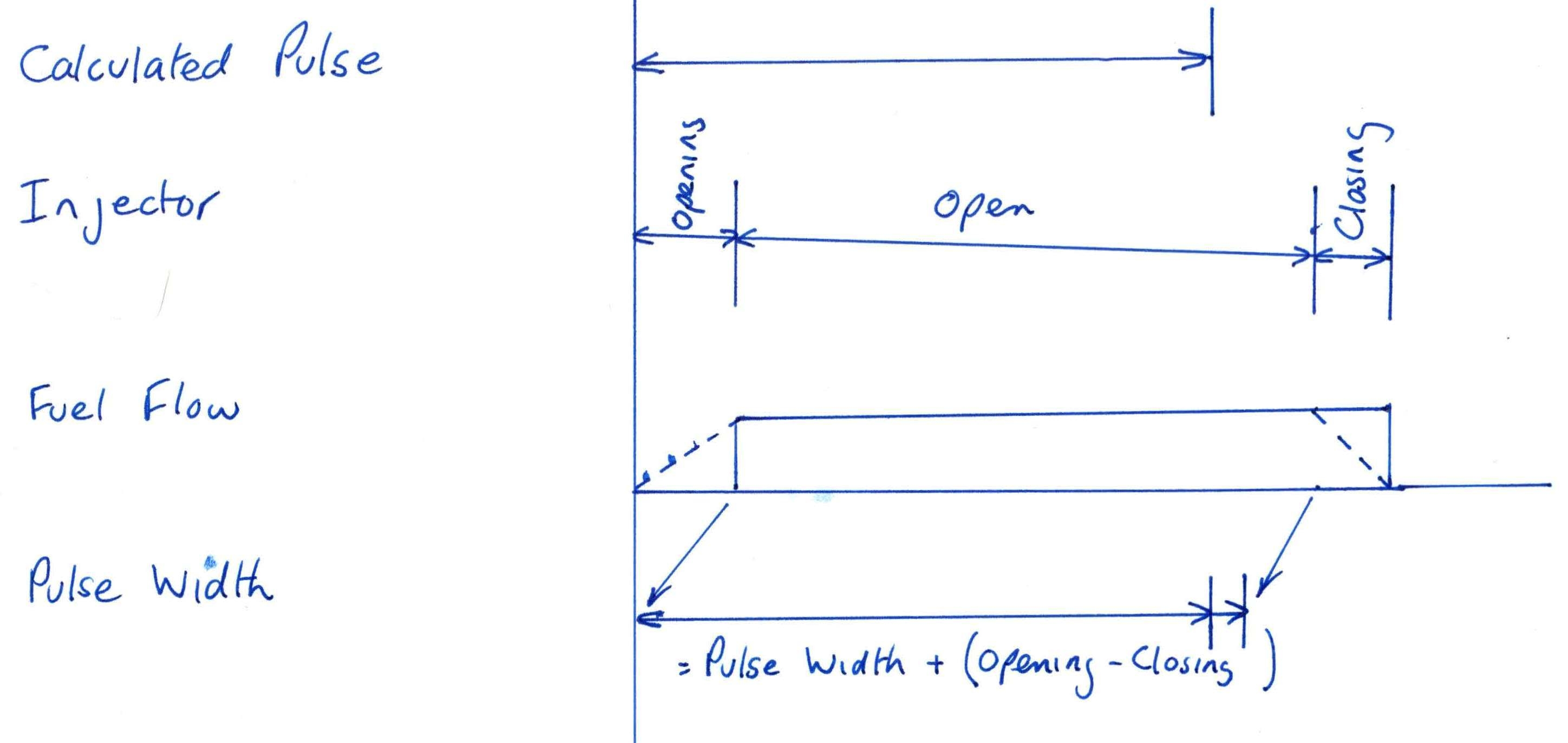

Yes, the "dead" time is open and close added I beg to differ. Apologies for poor sketch, but it's the best way to explain it:

Edited by Paul S on 24th Jun, 2014. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

24th Jun, 2014 at 11:52:12am

We'll have to disagree then but, from the manual,

Edited by Rod S on 24th Jun, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

24th Jun, 2014 at 11:59:46am

It is a bit of a fudge. The more I think about it, the more complex it becomes.

Edited by Paul S on 24th Jun, 2014. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

24th Jun, 2014 at 12:41:05pm

On 24th Jun, 2014 Paul S said:

It is a bit of a fudge. The more I think about it, the more complex it becomes. If you add both the opening and closing times to the calculated pulse width, then you will have too much fuel. Agreed, because some fuel will be flowing during the open/close (dead time figure) you enter on top of the calculated req'd fuel value (req'd fuel and multipliers). On 24th Jun, 2014 Paul S said:

The MS manual says to calculate the dead time by subtracting the closing time from the opening time, but then this is only an approximation. I hadn't actually read that bit but presumably they are trying to create an average based on close being faster than open ??? However, that is very much down to electrical characteristics (flyback is used to close injectors fast but is probably completely different on LPG injectors, especially if Robert has one of the early boards (I can't remember) or is using resistors (can't remember)). On 24th Jun, 2014 Paul S said:

Best actual build a test rig and measure it, but I doubt Rovert can do that with LPG. Yes, as I mentioned earlier, the best way but probably not possible with LPG. On 24th Jun, 2014 Paul S said:

However in Rovert's case and long opening and closing times, the method introduces a lot of error. He needs to experiment as stated above. Yes, seems the best way. I didn't bother with the squirt it into a bottle and measure it way and can't do the changing squirts method (as the siamese code fixes the squirts to one per cylinder) but I watched the AFRs at idle with differing dead time settings and req'd fuel settings and soon found out the approximate actual dead time value. Schrödinger's cat - so which one am I ??? |

||||||

6752 Posts Member #: 828 Post Whore uranus |

24th Jun, 2014 at 01:09:52pm

hi chaps,

Edited by robert on 24th Jun, 2014. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

24th Jun, 2014 at 02:20:30pm

Is your gas pressure regulator reference to intake vacuum (MAP)?

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

6752 Posts Member #: 828 Post Whore uranus |

24th Jun, 2014 at 02:30:23pm

yes paul referenced to inlet vac , vac at tickover is 20 in hg. gas pressure on full throttle is 12 psi . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

24th Jun, 2014 at 03:10:49pm

Did you ever run this engine on the MS with petrol?

Edited by Paul S on 24th Jun, 2014. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

6752 Posts Member #: 828 Post Whore uranus |

24th Jun, 2014 at 06:52:53pm

no I didn't paul , it has not run petrol fro about 5 years I think .

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

24th Jun, 2014 at 08:21:43pm

ms tip in issues are something i had issue with for ages. when they intriduced the hybrid accel enrichment it helped tonnes. as i could tweak mapdot and tpsdot. changing to 4 squirts/cycle helped massively too. the icing on the cake was to make the cells on the VE table above where the car rests at idle slightly richer than necesary. it ment on cruise and transitions at ccruise could get a little ugly. with the injectors being so "laggy" i dint think youll be able to completely eliminate the throttle tip-in issues. :/ turbo 16v k-series 11.9@118.9 :)

|

||||||

6752 Posts Member #: 828 Post Whore uranus |

25th Jun, 2014 at 05:35:48pm

that's sounds good denis , I only have it on tps enrichment at the mo ,that doesn't seem to do much immediately the pdals pressed , I will have to have a look at the map related one too .this used to be called asynchronious enrichment years ago !

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

25th Jun, 2014 at 06:56:59pm

Using 4 squirts/cycle is a kludge that is useful when using batch injection: that gives you more pulse width updates for a more up-to-date fueling. The real solution is full sequential injection where you get the same number of pulse width updates but with a more efficient use of the injectors.

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

25th Jun, 2014 at 07:17:40pm

On 25th Jun, 2014 jbelanger said:

Using 4 squirts/cycle is a kludge that is useful when using batch injection: that gives you more pulse width updates for a more up-to-date fueling. The real solution is full sequential injection where you get the same number of pulse width updates but with a more efficient use of the injectors. Jean im still on ms1-extra and waaaay behind the curve on whats doing these days, just mentioning what worked for me :) turbo 16v k-series 11.9@118.9 :)

|

||||||

6752 Posts Member #: 828 Post Whore uranus |

26th Jun, 2014 at 06:10:04pm

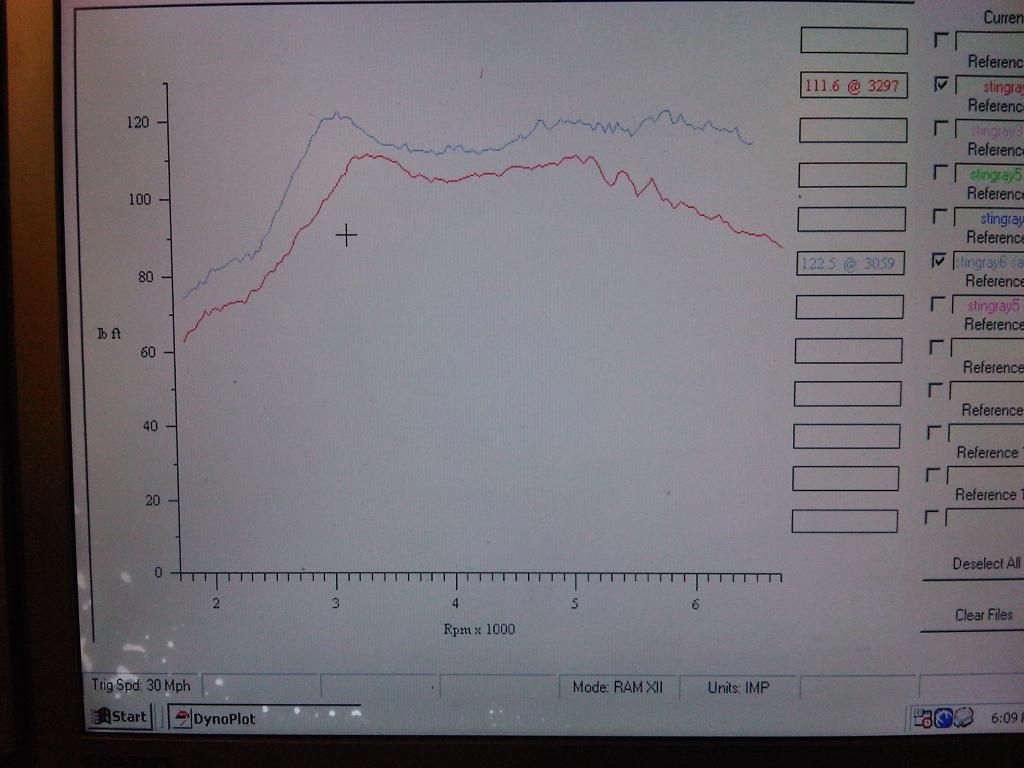

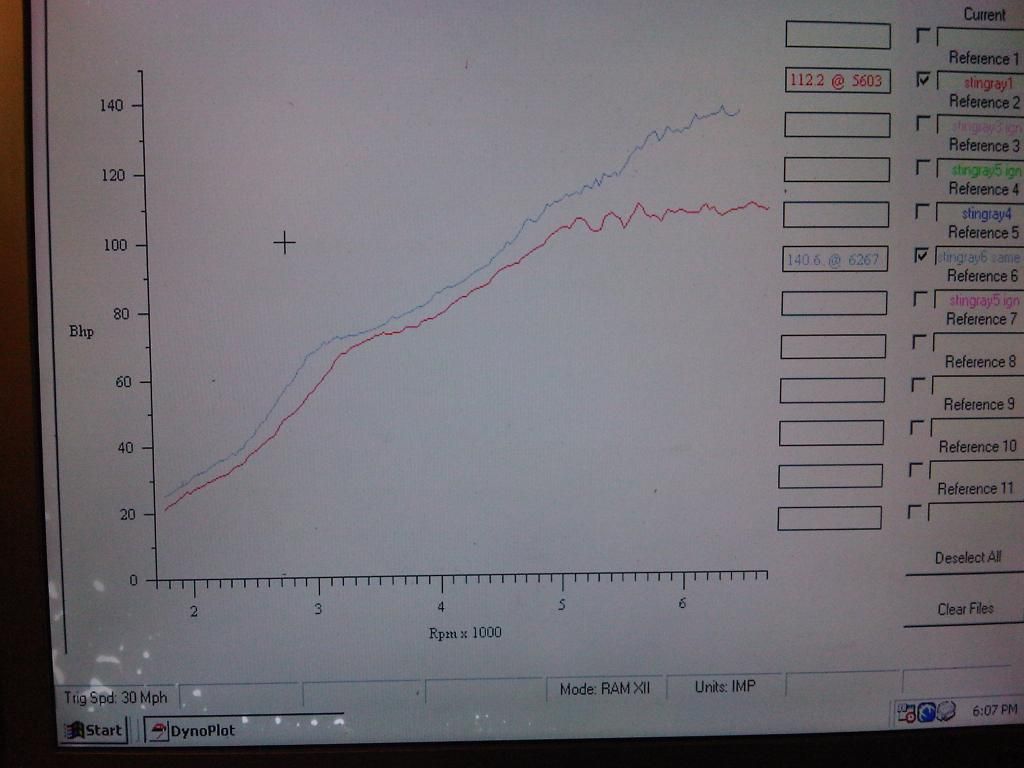

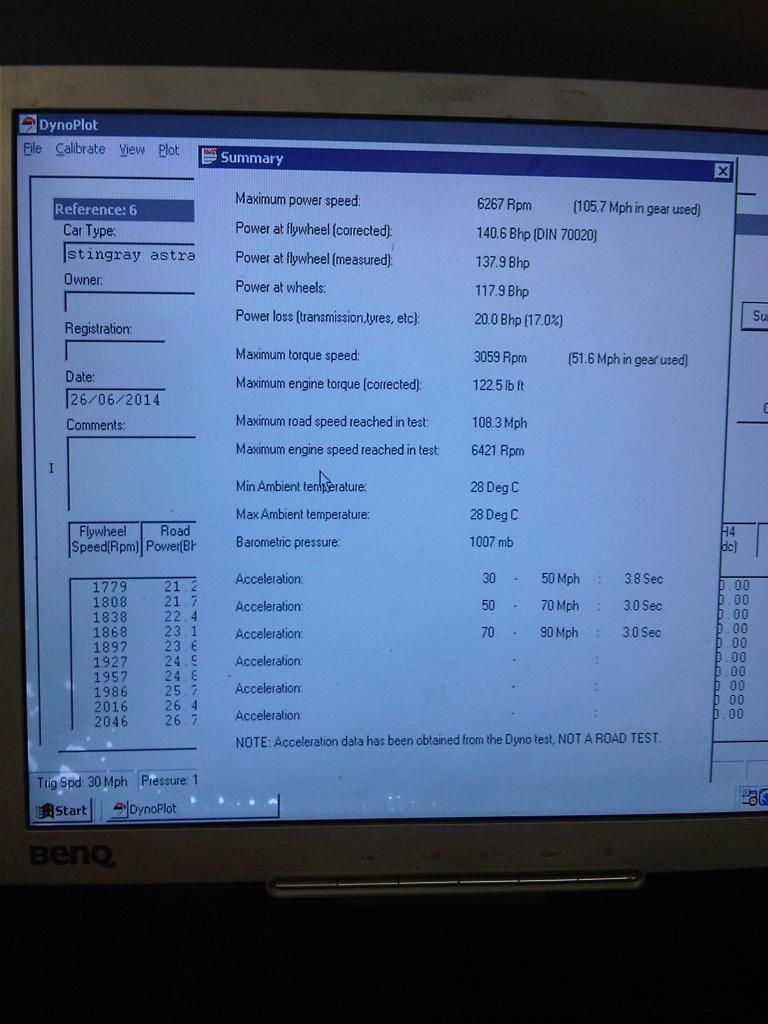

bit of afternoon fun in the batcave ...

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

26th Jun, 2014 at 06:36:58pm

Fantastic!

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

6752 Posts Member #: 828 Post Whore uranus |

26th Jun, 2014 at 07:12:52pm

joe, its at 5 psi up to 4500rpm, then climbing to 8psi at the top rpm .( due to a small wastegate flap).this give a nice level trq curve so im leaving it that way .oh yes . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

26th Jun, 2014 at 07:17:51pm

well thats a pretty decent figure then. On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

6752 Posts Member #: 828 Post Whore uranus |

26th Jun, 2014 at 07:27:10pm

yup not bad , but then it does have a 38mm inlet valve ...as standard !

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

26th Jun, 2014 at 09:18:52pm

Good result Robert. In the 13's at last!.. Just |

||||||

6752 Posts Member #: 828 Post Whore uranus |

27th Jun, 2014 at 06:30:12am

thanks gary ,looking forward to driving it today .I think its going to be wheelspin central Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

3006 Posts Member #: 2500 Post Whore Buckinghamshire |

27th Jun, 2014 at 08:36:50am

You know, I have read all this and I think I even understand that last bit !

|

||||||

| Home > Show Us Yours! > astra 1.4 8valve lpg turbo. | |||||||

|

|||||||

| Page: |