| Page: |

| Home > Show Us Yours! > project 31 8k 5 port | |||||||

1137 Posts Member #: 1450 Post Whore Near Paris - France |

5th Jul, 2012 at 04:14:29pm

I assume there is :

Rusty by nature

On 23rd Jun, 2008 paul wiginton said:

They said "That sounds rough mate." I said "Cheers it cost me a fortune to make it sound like that!" |

||||||

|

510 Posts Member #: 1592 Smart Guy! mainland europe near ze germans |

8th Jul, 2012 at 12:18:52pm

this might be of some use:

Edited by Sir Yun on 8th Jul, 2012. That sir, is not rust, it is the progressive mass reduction system

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

12th Jul, 2012 at 08:09:01pm

yunmiester, what weight of piston and rod was that for ?

Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

510 Posts Member #: 1592 Smart Guy! mainland europe near ze germans |

12th Jul, 2012 at 09:06:04pm

Hi robert,

Edited by Sir Yun on 12th Jul, 2012. That sir, is not rust, it is the progressive mass reduction system

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

16th Jul, 2012 at 06:54:45pm

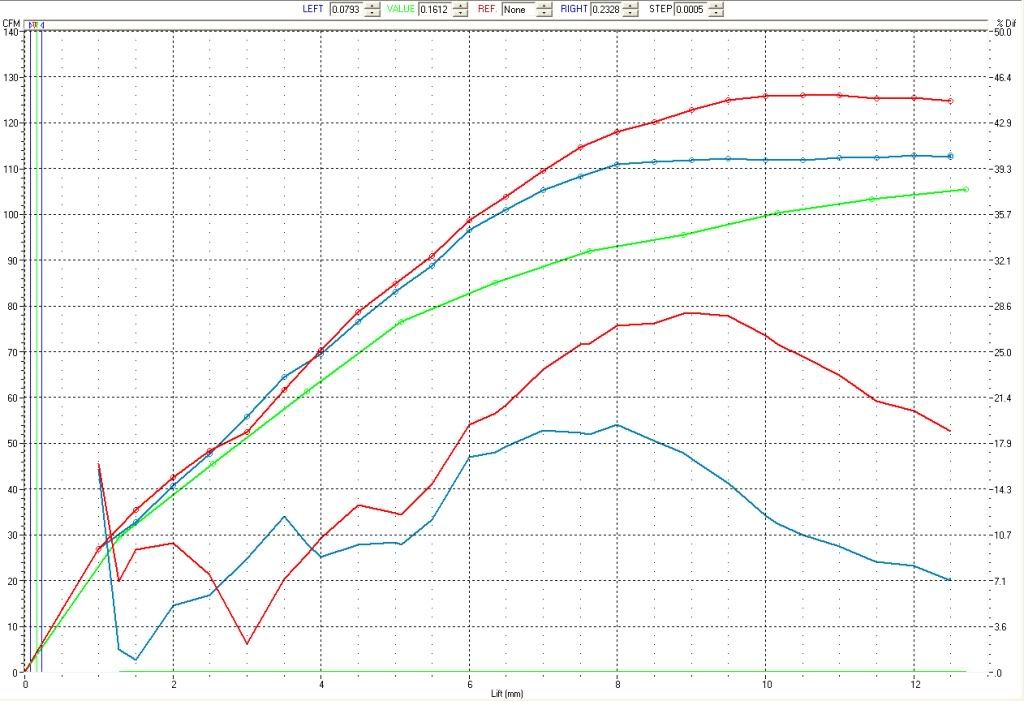

bit of progress , red is new port design ,and the jiggly lines below are the % improvements over a stock 33mm port ..

Edited by robert on 16th Jul, 2012. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

|

319 Posts Member #: 1742 Senior Member essex |

16th Jul, 2012 at 07:30:51pm

nice. now thats a handy bit of kit

My small bore turbo project http://www.turbominis.co.uk/forums/index.php?p=vt&tid=473901 |

||||||

|

614 Posts Member #: 2153 Post Whore kings langley |

16th Jul, 2012 at 08:36:33pm

this really is cool! Speeding is like masturbating, everyone does it, but not all of us film it and put it on the internet

|

||||||

|

432 Posts Member #: 2726 Senior Member wakefield |

16th Jul, 2012 at 09:07:28pm

Wish I had such a fun toy in my shed to tinker with. Good stuff. |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

16th Jul, 2012 at 09:14:20pm

been playing with the seats robert? On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

510 Posts Member #: 1592 Smart Guy! mainland europe near ze germans |

17th Jul, 2012 at 07:19:01am

impressive gains !! . i reckon its changed just below the seat area ? That sir, is not rust, it is the progressive mass reduction system

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

17th Jul, 2012 at 03:24:36pm

On 17th Jul, 2012 Sir Yun said:

impressive gains !! . i reckon its changed just below the seat area ? hi chaps ,, seat work tends to help low lift flows , its more throat and guide work to remove larger high lift flow restrictions ...whilst of course trying to keep speed up ,and c.s.a. down .just ordered some port putty to try filling in dead areas .i have not actually done any work on the seats yet . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

17th Jul, 2012 at 07:54:53pm

Some old geezer earlier in the year was telling me that they have started adding material in certain areas of the port, to gain an increase. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

510 Posts Member #: 1592 Smart Guy! mainland europe near ze germans |

17th Jul, 2012 at 08:18:43pm

i have seen a lot of filled ports but i'm always worried it comes off and gets munched .. That sir, is not rust, it is the progressive mass reduction system

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

17th Jul, 2012 at 08:20:05pm

Depends on the glue,

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

6745 Posts Member #: 828 Post Whore uranus |

17th Jul, 2012 at 08:29:01pm

Asi thought then.impressive gains ,i have to see of there is room for improvement in my head as well . how much lift are you going to run ? if you use 1.5 rockers you get quite a bit of lift on overlap with most cams and i don't know if you want that with a turbo.on the other hand without high lift rockers it is hard to get adequate lift without big lifters and a billet profile I think. it was not NA was it ?!

my original model used a lower flow head ,so my cam will change spec ,but i am expecting ti run between 420 and 520 thou lift . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

| Home > Show Us Yours! > project 31 8k 5 port | |||||||

|

|||||||

| Page: |