| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

1391 Posts Member #: 1686 Post Whore Oxford |

9th Jun, 2014 at 06:48:36pm

Good bit of work!

On 19th Feb, 2011 Miniwilliams said:

OMG Robert that's a big one |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

9th Jun, 2014 at 08:25:12pm

Not quite, it's machined out of billet. The bulk of it was milled out, then lightening it involved some milling of pockets (there are 2 10mm pockets on the underside) and I pocketed out around the mounting holes. But then rest of the tidying up was done by manual cutting and filing and a bit of chain drilling added into the mix. Edited by matty on 9th Jun, 2014. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

1391 Posts Member #: 1686 Post Whore Oxford |

9th Jun, 2014 at 08:33:22pm

I did think you cant have welded that and smoothed it out. Although with the plate on the head as an example it doesn't surprise me.

On 19th Feb, 2011 Miniwilliams said:

OMG Robert that's a big one |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

9th Jun, 2014 at 08:46:19pm

It takes a while, but you get used to doing it, when you weld up lots of castings and have to make the repairs invisible. Sheet ally dashboards/bulkheads are fun to repair too. Lol https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Jun, 2014 at 04:10:03pm

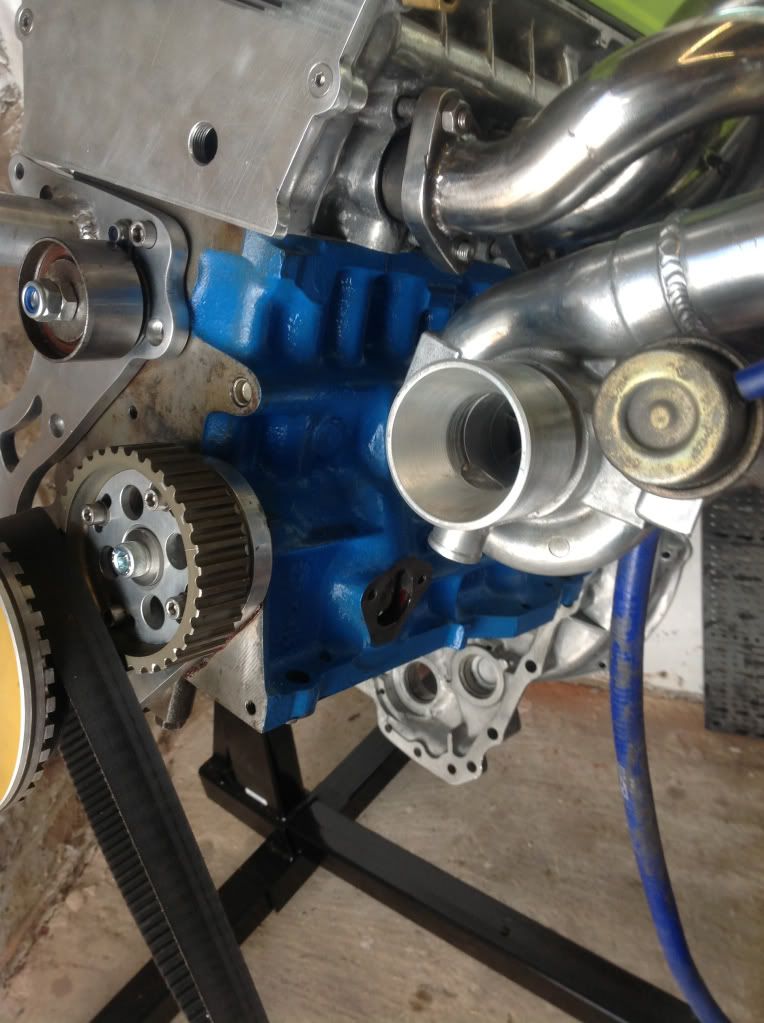

A few more bits done.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

13th Jun, 2014 at 04:42:04pm

Looking neat

I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

13th Jun, 2014 at 05:51:57pm

any chance of pointing that pipe downwards and running it round the sump matt .?ever so close to the headers . Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Jun, 2014 at 10:05:14pm

Yeah it normally sits a little bit further away, I'm waiting for a new o ring before I finally fit the compressor housing in the correct position.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

14th Jun, 2014 at 06:30:12am

Nice thought Matt - mind if I borrow it ?

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

16th Jun, 2014 at 06:23:46pm

No go ahead Dave. Does yours run close to the manifold too then?.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

17th Jun, 2014 at 05:16:59am

Mine runs as close as yours and actually scorched the silicone hose so needs to be re -worked.

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

17th Jun, 2014 at 08:07:42am

This is an issue i have encountered gents, simply putting one (ideally two) sheets of metal between manifold and the hose is enough to stop it being an issue. i usually make a square with a wee tag, fold the tag over, and tuck it under a jubilee clip. im sure you will come up with nicer solutions. turbo 16v k-series 11.9@118.9 :)

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

17th Jun, 2014 at 09:58:30am

I tried 2 layers of heat resistant aluminised cloth but wasn,t convinced that it would do. |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

17th Jun, 2014 at 11:23:23am

how about ceramic coating the housing and or manifold?

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

17th Jun, 2014 at 12:53:34pm

On 17th Jun, 2014 tadge44 said:

I tried 2 layers of heat resistant aluminised cloth but wasn,t convinced that it would do. did you actually run with it though? Iv done it to a few cars now with tubular manifolds where compressor outlet placement is less than ideal and its never failed. even if manifold - plate - silicone are nearly touching. I think its the infra-red radiaton more than the actual temperature that messes up the silicone. however, has worked for me. turbo 16v k-series 11.9@118.9 :)

|

||||||

|

72 Posts Member #: 8845 Advanced Member |

17th Jun, 2014 at 12:55:00pm

Gold reflective tape around the inlet tube would help, wouldn't believe what that stuff can reflect.

|

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

17th Jun, 2014 at 05:21:57pm

On 13th Jun, 2014 matty said:

Has anyone plumbed a vacuum off the turbo intake to the breather system? yes i used it in conjunction with one from the manifold, with 1 way valves to keep the crank case pressure down ( supposedly ) mine was a slightly re designed stock layout - that had a habit of sucking oil out the cam covers into the turbo i couldnt stop it from getting oil pre turbo so i blocked it off Yes i moved to the darkside |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

17th Jun, 2014 at 07:33:39pm

I'll have a look into how hot the turbo outlet gets on running. From memory there is about 15-20mm gap between the outlet and the manifold, so it should be possible to get some form of heat shield on there. I'll probably weld a couple of threaded lugs on the outlet just I case I do go down that route in the future.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

17th Jun, 2014 at 08:12:26pm

On 17th Jun, 2014 matty said:

I'll have a look into how hot the turbo outlet gets on running. From memory there is about 15-20mm gap between the outlet and the manifold, so it should be possible to get some form of heat shield on there. I'll probably weld a couple of threaded lugs on the outlet just I case I do go down that route in the future. Cheers brett, its slowly getting there! I've googled oil breather plumbing and nearly all of them have some form of vacuum running off the turbo intake or on NA off the intake manifold. I was thinking of running one from the turbo inlet to an oil breather catch tank, then have all my breathers connected to the catch tank, so they are all positive pressure is being drawn out. My main concern like you say is drawing oil into the turbo inlet though? I vent my can under the floor, when the engines healthy there should be no oil entering the inlet stream. the problem is if you do get a little detonation or something goes amis that pressurizes the crankcase, you end up with oil getting forced thro, you wont notice it cause the engines burning it, so you keep running and do more harm. with it venting under the floor, its clean when the engines healthy, but if you say crack a ringland, youll start to notice it breathing a little heavier than usual and you can nip the problem in the bud rather than risking the rest of your pistons, oil ingress etcetc. IMHO as always. iff you want an evacuated sump i'd sooner plumb the breather into a nice free flowing exhaust

turbo 16v k-series 11.9@118.9 :)

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

17th Jun, 2014 at 08:20:08pm

me too. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

17th Jun, 2014 at 08:30:00pm

Would you get away with venting it under the car for track days? I've always had my venting in the engine bay, but I did get an oil mist around the breather filter, and I was fed up of having oil everywhere, especially when it came to scrutineering.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

17th Jun, 2014 at 08:55:56pm

modern cars have baffles and gause in the rocker covers to seperate oil mist out. Provided the engines healthy it does the trick, or it should do.

turbo 16v k-series 11.9@118.9 :)

|

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

17th Jun, 2014 at 09:17:54pm

Don,t know what I did wrong but when I tried evacusump it didn,t seem to help at all.

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

18th Jun, 2014 at 11:15:38am

ill be ventinting to atmosfeare and hope its ok

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

18th Jun, 2014 at 04:25:25pm

Righty I've found a really good site about oil breather systmes and I'm going to go for an oil separator/catch tank with a gauze and a vacuum feed running off the turbo inlet. I've nearly finished my catch tank, but I got distracted by the arrival of a new gearbox shaft! Edited by matty on 18th Jun, 2014. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |