| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

12th Nov, 2013 at 09:36:37pm

New engine mount, how's it's looking at the moment. I'm looking at adding a crank trigger bracket and possibly incorporate a cam sensor bracket onto it too.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

520 Posts Member #: 189 Post Whore Norway |

12th Nov, 2013 at 09:46:08pm

Thats a beutiful engine mount! www.shag.no |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

12th Nov, 2013 at 09:52:56pm

Nice work! I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

12th Nov, 2013 at 10:42:07pm

Nice engine mount, how did you make that? Did you make it in 3, then weld it up? Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

12th Nov, 2013 at 11:05:38pm

Yeah, made it in 3 parts then just welded them together. The edges of the plates were positioned so the weld was a fillet instead of external corner if that makes sense? It made it easy to blend them as I wanted it to look like its not lots of parts welded together and more factory looking. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

13th Nov, 2013 at 07:19:47am

This thing is a work of art! In the 13's at last!.. Just |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

13th Nov, 2013 at 10:20:41am

The bearing retainer is sintered steel giving the impression of being cast. To a degree I suppose it is cast, but then to a degree it is also forged On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

13th Nov, 2013 at 10:36:44am

On 12th Nov, 2013 matty said:

Yeah, made it in 3 parts then just welded them together. The edges of the plates were positioned so the weld was a fillet instead of external corner if that makes sense? It made it easy to blend them as I wanted it to look like its not lots of parts welded together and more factory looking. Nice job! is mine like this too? Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Nov, 2013 at 08:04:18pm

Yep looks exactly the same, although I made yours out of lead for a nice bit of ballast. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

Forum Mod  5933 Posts Member #: 784 9 times Avon Park Class C winner Milton Keynes |

13th Nov, 2013 at 09:20:22pm

That engine mount bracket is great mate, similar to my titanium one I seriously doubt it! |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

13th Nov, 2013 at 09:34:00pm

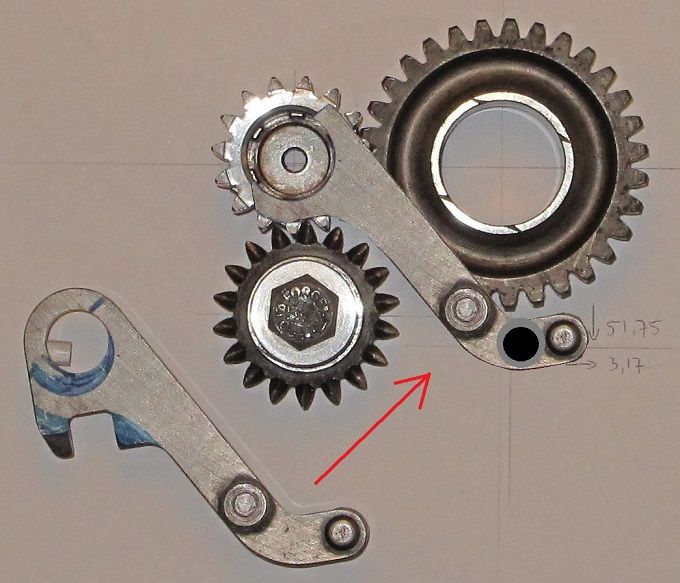

Happy to read the steel welding went fine, Matt. I will continue with that too. Here is the draft of my plate now (size is related to the available material)

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Nov, 2013 at 10:08:46pm

Which mini gear are you using that needs the splines grinding out then?

Edited by matty on 13th Nov, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

Forum Mod  5933 Posts Member #: 784 9 times Avon Park Class C winner Milton Keynes |

13th Nov, 2013 at 10:24:06pm

I dont see a problem with progressively sized holes aslong as theyre deburred and finished nicely like the rest of it I seriously doubt it! |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

13th Nov, 2013 at 10:26:44pm

Matt,

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Nov, 2013 at 10:33:45pm

Ah I see, I thought it was for reverse gear.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Nov, 2013 at 10:36:15pm

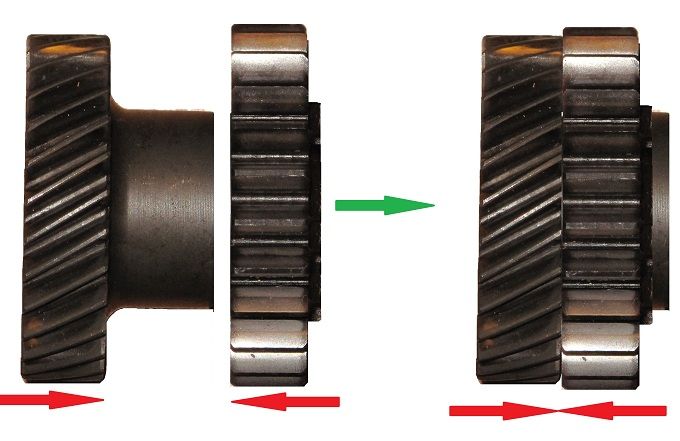

Oh yeah, you'll also have to elongate the splines on the 1st motion shaft, as you will have to remove the under cut from the inner gear. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

14th Nov, 2013 at 04:12:17pm

It will not be shrink fit only, there is some room for a TIG weld too.

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

14th Nov, 2013 at 05:22:58pm

The two standard 1st motion gears have an undercut/counterbore at the end of the boss to clear the splines on the it's motion shaft where the cutter has ran out to the inner bearing diameter. If you remove the boss from the gear, then it doesn't butt up to the bearing, unless you relieve the splines. If that makes sense? https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

30th Nov, 2013 at 09:20:18pm

As my workshop has all been packed up due to moving, I've been cracking on with this during my breaks at work.

Edited by matty on 30th Nov, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

1st Dec, 2013 at 07:02:16am

oh thank god for that.... assembled for new year ? Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

1st Dec, 2013 at 08:12:04am

Probably not, I'm moving house next week so I've got weeks of the usual DIY and sorting the new workshop out.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

20th Dec, 2013 at 10:31:11pm

Well after two weeks of no Internet I can update my progress!

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

562 Posts Member #: 9285 Post Whore Oxfordshire |

21st Dec, 2013 at 01:00:07pm

It's all coming together now Mat! My build thread: http://www.turbominis.co.uk/forums/index.php?p=vt&tid=454802

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

21st Dec, 2013 at 06:05:29pm

It sure is, my new input gear arrived today too. Edited by matty on 21st Dec, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

562 Posts Member #: 9285 Post Whore Oxfordshire |

21st Dec, 2013 at 06:28:02pm

I will have a look for you tomorrow mate, is it for mocking up purposes or does it need to be in good condition? My build thread: http://www.turbominis.co.uk/forums/index.php?p=vt&tid=454802

|

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |