| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

1425 Posts Member #: 9199 Post Whore Lancashire |

1st Oct, 2013 at 06:48:54am

loving the oil drain, may i ask where its from or was this a home scuptured item.

What the mind can conceive the mini can achieve

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

1st Oct, 2013 at 01:32:46pm

On 1st Oct, 2013 lee.pb said:

loving the oil drain, may i ask where its from or was this a home scuptured item. great build look forward to more  Looks like type of stainless tube typically used for EGR on modern engines, but I can be wrong... |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

1st Oct, 2013 at 04:11:55pm

Looks like an OEM oil drain tube, used on lots of rovers etc On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

1st Oct, 2013 at 08:30:24pm

Streetscreamer - my ecu has shift cut on it, so I'll just have it wired to the up shift microswitch mounted on the gear shifter. I'll have a second microswitch mounted on the shifter and may look into a throttle blipped in the future for down shifts if everything else works fine.

Edited by matty on 1st Oct, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

1st Oct, 2013 at 09:58:08pm

see me.. as total noob regarding turbo goodies... didnt see a std saab item in it.

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

1st Oct, 2013 at 10:16:45pm

At first I'll just try it out and see how consistent changes are, if they appear to be easy to miss I'll mess around with pressures Etc..And consider making up a simple timer circuit. My old job used to involve pneumatics a lot, especially the timings of solenoids, so to be honest im fairly confident setting it up without a timer shouln't be a problem, and will make getting neutral easier too!

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

25th Oct, 2013 at 09:11:47pm

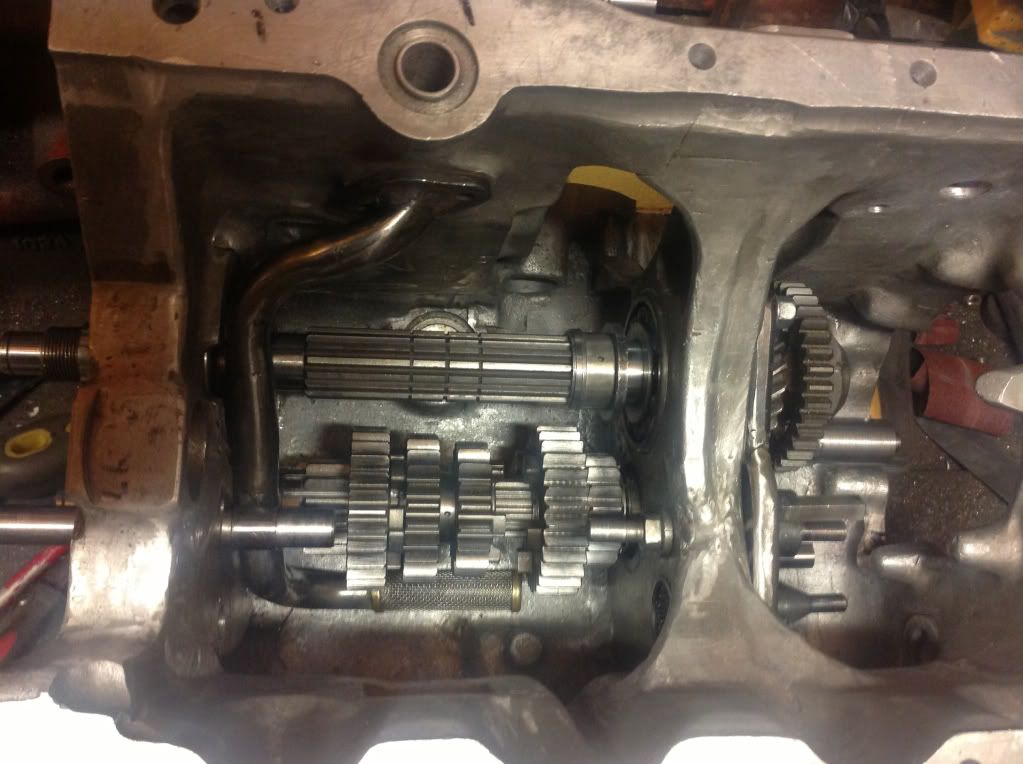

Well it's been a while since an update! I've been busy building my engine up, grinding rods to size, and thrusts which is all ready for balancing now.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

562 Posts Member #: 9285 Post Whore Oxfordshire |

25th Oct, 2013 at 09:30:08pm

Looking like some good progress matt! I like the look of the pick up pipe My build thread: http://www.turbominis.co.uk/forums/index.php?p=vt&tid=454802

|

||||||

|

4018 Posts Member #: 1757 Back to Fucking Tool status Swindon |

26th Oct, 2013 at 08:48:27am

I dont know if it is the camera but there looks like an area of stress left of the centre web a sort of sideways T shape, the rest of thd casing looks to be worked hope its not a crack Drives

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

26th Oct, 2013 at 11:33:06am

Cheers dan, those pipes worked a treat!

Edited by matty on 26th Oct, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

4018 Posts Member #: 1757 Back to Fucking Tool status Swindon |

26th Oct, 2013 at 02:15:23pm

Better to be safe than sorry! I saw it just randomly and the rest of the case looks pritty well done, thought I better say incase you missed it Drives

|

||||||

|

Forum Mod  5933 Posts Member #: 784 9 times Avon Park Class C winner Milton Keynes |

26th Oct, 2013 at 02:27:26pm

How many casings have we ever known to break? Not many, I only know of Fastcarls. Really its nothing to worry about I seriously doubt it! |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

26th Oct, 2013 at 02:57:56pm

I have a casing where the diff has tried to climb out of the back, has a nice big split round the diff housing. On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

26th Oct, 2013 at 05:09:20pm

On 26th Oct, 2013 Paul R said:

Better to be safe than sorry! I saw it just randomly and the rest of the case looks pritty well done, thought I better say incase you missed it  . .

Sorry for worrying you Haha no worries, I haven't spent all that long cleaning up the casting marks, but it's going to be the next big job. Because of all the work done to the casing, and trying to make it look as factory as I can, means cleaning up all of it to make it look right. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

27th Oct, 2013 at 06:55:30am

Good job Matty.

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

27th Oct, 2013 at 08:56:23am

Cheers Bart, having it in constant mesh was a concern of mine too which and this seemed to be the best solution. All three gears will be giving a lead to help them mesh easier.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

30th Oct, 2013 at 09:41:28pm

Cute solution for the oil pick up support Matty!

|

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

30th Oct, 2013 at 10:15:31pm

So does this mean you have six reverse gears as well?

Edited by TurboDave16V on 30th Oct, 2013. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

11th Nov, 2013 at 07:31:26pm

I've been cracking on with this, and getting all of the last few jobs done.

Edited by matty on 11th Nov, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

2057 Posts Member #: 9252 Post Whore Cleethorpes |

12th Nov, 2013 at 05:35:47am

great looking work as always matty Done now needs redoing lol |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

12th Nov, 2013 at 11:08:11am

Don't foroget your making one of these for me too Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

3756 Posts Member #: 1709 I like granny porn. LONDONSHIRE |

12th Nov, 2013 at 12:36:13pm

On 12th Nov, 2013 Jimster said:

Don't foroget your making one of these for me too On 2nd Oct, 2009 Vegard said:

On 1st Oct, 2009 Jimster said:

I bet my first wank came quicker than your first mini turbo These new modern turbos with their quick spool up time, would make the competition harder. On 15th Aug, 2011 robert said:

phew!!! thank you brett for smashing in my back doors .( not something i imagined writing... EVER) |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

12th Nov, 2013 at 12:50:10pm

lol, I'll move Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

12th Nov, 2013 at 03:17:34pm

Sexy pics again, yum yum!

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

12th Nov, 2013 at 09:23:02pm

Thanks for the comments.

Edited by matty on 12th Nov, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |