| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

11th Jun, 2013 at 09:55:20pm

Yep it does get pretty frustrating, but I try and get as many jobs as I can with the gearset in place, then once removed get as many jobs on the casing done as I can. I've had the selector arm out about 10 times this evening just to drill 3 holes. Lol but its getting there! Fingers crossed I can properly test the mechanism out tomorrow. :) https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

|

160 Posts Member #: 1085 Advanced Member Netherlands |

13th Jun, 2013 at 11:48:12pm

soo, did it work? :)

1963 Cooper

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

14th Jun, 2013 at 09:26:33pm

Haha kind of!

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

22nd Jun, 2013 at 12:23:13pm

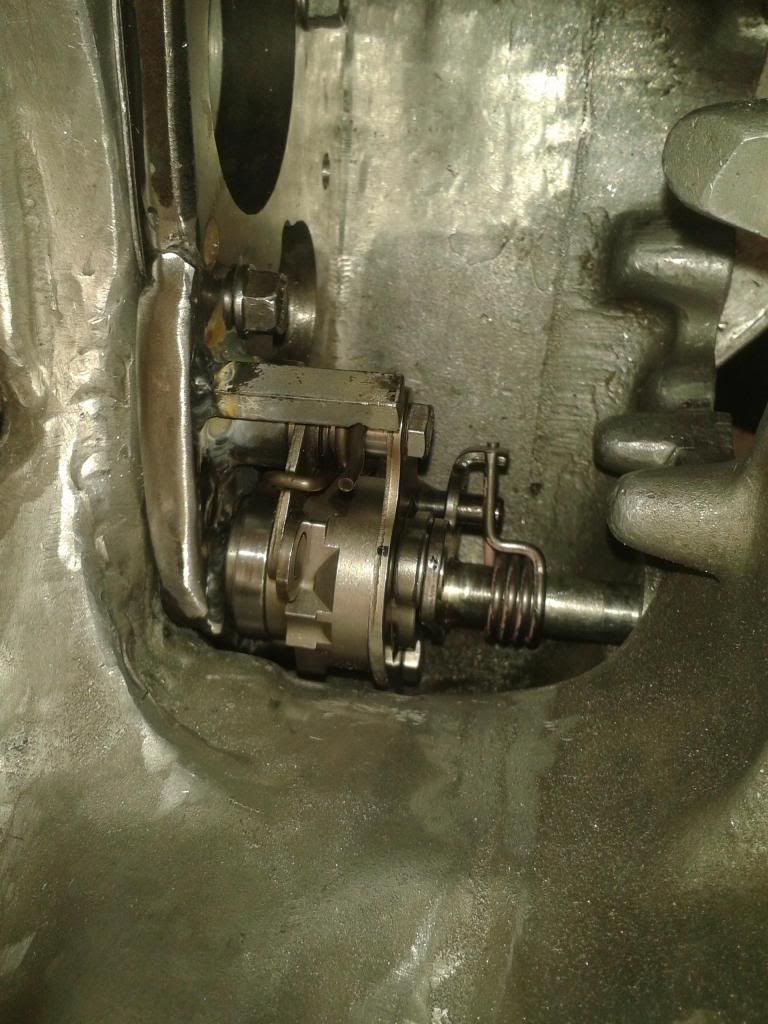

Some more bits made for the box. :)

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

233 Posts Member #: 863 Senior Member Lathom, lancs |

24th Jun, 2013 at 11:12:57am

Good god, just spent all morning reading through this. Top work chap! All the best with the first thrashing! |

||||||

720 Posts Member #: 2588 Post Whore Pretoria South Africa |

24th Jun, 2013 at 01:17:51pm

EPIC ! "So wat we gonna do tonight Brain?"

|

||||||

10021 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

24th Jun, 2013 at 01:30:14pm

X on the front of the block eh? I was once told that meant it was a gen turbo block.

If something is worth doing, it's worth doing half of. |

||||||

10021 Posts Member #: 1456 Mongo Barnsley, South Flatcapshire |

24th Jun, 2013 at 01:30:36pm

Top progress btw! If something is worth doing, it's worth doing half of. |

||||||

|

4304 Posts Member #: 1321 Post Whore Wiltshire |

24th Jun, 2013 at 06:39:00pm

I like the idea of that massive plate there helping tie the centre web to the back of the casing. On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

26th Jun, 2013 at 11:33:24am

Interesting bits for the shifter mech Matt!

Edited by Streetscreamer on 26th Jun, 2013. |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

26th Jun, 2013 at 05:14:20pm

Yeah it's a genuine turbo block, I have to admit I can't remember seeing a block with an x on the front either. On 24th Jun, 2013 John said:

X on the front of the block eh? I was once told that meant it was a gen turbo block. None of the turbo block I've had ever had this tho! Lol https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

26th Jun, 2013 at 05:17:05pm

Thanks for the comments.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

17th Jul, 2013 at 08:34:20pm

Ow yeahhh... got my shafts nearly done! Only waiting for chemical hardening...

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

17th Jul, 2013 at 08:56:32pm

Nice Shaft! I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

17th Jul, 2013 at 09:06:14pm

On 17th Jul, 2013 gr4h4m said:

Nice Shaft!

I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

17th Jul, 2013 at 09:17:40pm

On 17th Jul, 2013 madmk1 said:

On 17th Jul, 2013 gr4h4m said:

Nice Shaft!   I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

5417 Posts Member #: 6181 Double hard bastard brookwood woking |

17th Jul, 2013 at 09:40:45pm

HaHa when I get 5mins at home.

On 17th Jul, 2013 gr4h4m said:

Stop smiling and go and take some pics of that car of yours... :) On 17th Jul, 2013 madmk1 said: On 17th Jul, 2013 gr4h4m said:

Nice Shaft!   I have started posting on Instagram also my name on there is turbomk1golf

On 1st Nov, 2007 Ben H said:

There is no such thing as 'insignificant weight saving', it all adds up. |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

8th Aug, 2013 at 09:21:28pm

They look good! Have you worked out how you're going to do the case yet?

Edited by matty on 8th Aug, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

9th Aug, 2013 at 10:34:22am

Hi Matt,

|

||||||

|

971 Posts Member #: 3228 Post Whore North of the Netherlands |

9th Aug, 2013 at 04:30:35pm

Amazing stuff going on here.

Dazed and Confused.... |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

9th Aug, 2013 at 07:41:19pm

Here's some pics of the transfer housing as it stands. I still need to finish off the blending etc...but it's taking shape! :)

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

131 Posts Member #: 10521 Advanced Member Aberdeen |

9th Aug, 2013 at 08:36:37pm

Matty just read your full build thread, must admit your engineering skills are shit hot. Do you do this sort of stuff for a living? Flat oot like a dukes fit! |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

10th Aug, 2013 at 02:47:23pm

Thanks, yeah for the past 12months my job is an engine builder working on the old Bugatti gp cars. As with anything that old the value is in the original parts, so repairing/welding up broken casting etc.. Is a regular thing at my work.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

520 Posts Member #: 189 Post Whore Norway |

10th Aug, 2013 at 07:19:56pm

On 10th Aug, 2013 matty said:

Thanks, yeah for the past 12months my job is an engine builder working on the old Bugatti gp cars. As with anything that old the value is in the original parts, so repairing/welding up broken casting etc.. Is a regular thing at my work. It's helped loads to have some decent machines to use for Machining, grinding etc...I also found the limits of my 200A welder trying to weld the transfer housing up! Sounds like a dream job. Id love doing that for a living www.shag.no |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

10th Aug, 2013 at 08:20:29pm

Matt you are blessed guy with such job! However some say when your hobby becomes your job, you've lost a hobby |

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |