| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

6745 Posts Member #: 828 Post Whore uranus |

8th May, 2013 at 04:26:39am

lovely neat job on the support pegs matt. Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

8th May, 2013 at 08:21:47am

I've got to say, I'm seriously impressed with this project. I'd love to have the engineering skills to even contemplate something like this, never mind achieve what you have |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

28th May, 2013 at 09:28:30pm

Thanks for the comments. :)

Edited by matty on 28th May, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

580 Posts Member #: 9580 Post Whore Surrey |

29th May, 2013 at 04:49:29am

Wow |

||||||

|

3004 Posts Member #: 2500 Post Whore Buckinghamshire |

29th May, 2013 at 05:05:21am

Wow squared.

|

||||||

|

Forum Mod  1927 Posts Member #: 1761 Stalker Bristol |

29th May, 2013 at 07:31:26am

Amazing work! Ready for MITP? |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

29th May, 2013 at 06:30:01pm

Ow yeah Matty, new pics! It look the recent bad weather helped you to make progress and not be laying on the beach |

||||||

1666 Posts Member #: 252 Post Whore Sunny suffolk |

29th May, 2013 at 07:41:10pm

Top quality workmanship

-MINI CLUBMAN 1380 TURBO- |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

29th May, 2013 at 08:12:11pm

Thanks for all the comments, is looking increasing more like it'll work day by day, I just hope it copes with the power. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

29th May, 2013 at 08:34:47pm

Blimey. That almost looks like it'll work.

In the 13's at last!.. Just |

||||||

|

4304 Posts Member #: 1321 Post Whore Wiltshire |

29th May, 2013 at 09:30:06pm

On 29th May, 2013 matty said:

Thanks for all the comments, is looking increasing more like it'll work day by day, I just hope it copes with the power.

What gearset where you running before, that must have taken some serious punishment. On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

29th May, 2013 at 09:53:59pm

On 29th May, 2013 matty said:

Streetscreamer - yep idler gear is going to be in constant mesh with input shaft and be 2 gears on one shaft kind of similar to the standard mini reverse gear. Right! So, still have to grind some off the tops of the  then then

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

29th May, 2013 at 09:54:50pm

I'm not too sure on the gearset, i got it second hand, that seems fine to be honest.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

3756 Posts Member #: 1709 I like granny porn. LONDONSHIRE |

29th May, 2013 at 11:17:37pm

Holy shit . On 2nd Oct, 2009 Vegard said:

On 1st Oct, 2009 Jimster said:

I bet my first wank came quicker than your first mini turbo These new modern turbos with their quick spool up time, would make the competition harder. On 15th Aug, 2011 robert said:

phew!!! thank you brett for smashing in my back doors .( not something i imagined writing... EVER) |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

30th May, 2013 at 02:26:00pm

how are you getting along with the 2nd box for me matt? Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

2nd Jun, 2013 at 11:39:06am

Haha it coming along nicely. :) https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

3673 Posts Member #: 9300 Post Whore Quarry Bonk |

2nd Jun, 2013 at 12:42:14pm

Just looked at your bulkhead inside the car. Are you running a rollcage/dash bar? Is there any need to stiffen that part of the shell back up if not? And if you have how have you done it? I want to tidy up my bulkhead and my lower dash rail is mashed up and I'm fitting a curley carbon dash so I want it out. On 26th Jan, 2012 Tom Fenton said:

ring problems are down to wear or abuse but although annoying it isn't a show stopper On 5th Aug, 2014 madmk1 said:

Shit the bed! I had snapped the end of my shaft off!! 17.213 @ 71mph, 64bhp n/a (Old Engine) |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

2nd Jun, 2013 at 05:05:55pm

I've used slightly thicker steel in the bulkhead panel, and where the horizontal and vertical panels meet there is an L section piece that is about 2mm thick.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

3673 Posts Member #: 9300 Post Whore Quarry Bonk |

2nd Jun, 2013 at 06:07:39pm

Thanks bud, I'm keeping the top rail anyway anyway so that's not a problem. I'll look into mine when I start cutting all the crap out.

On 26th Jan, 2012 Tom Fenton said:

ring problems are down to wear or abuse but although annoying it isn't a show stopper On 5th Aug, 2014 madmk1 said:

Shit the bed! I had snapped the end of my shaft off!! 17.213 @ 71mph, 64bhp n/a (Old Engine) |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

7th Jun, 2013 at 08:00:12pm

Yeah it'll be a nervous moment testing it! Lol but looking forward to it.

Edited by matty on 7th Jun, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

8th Jun, 2013 at 03:12:58pm

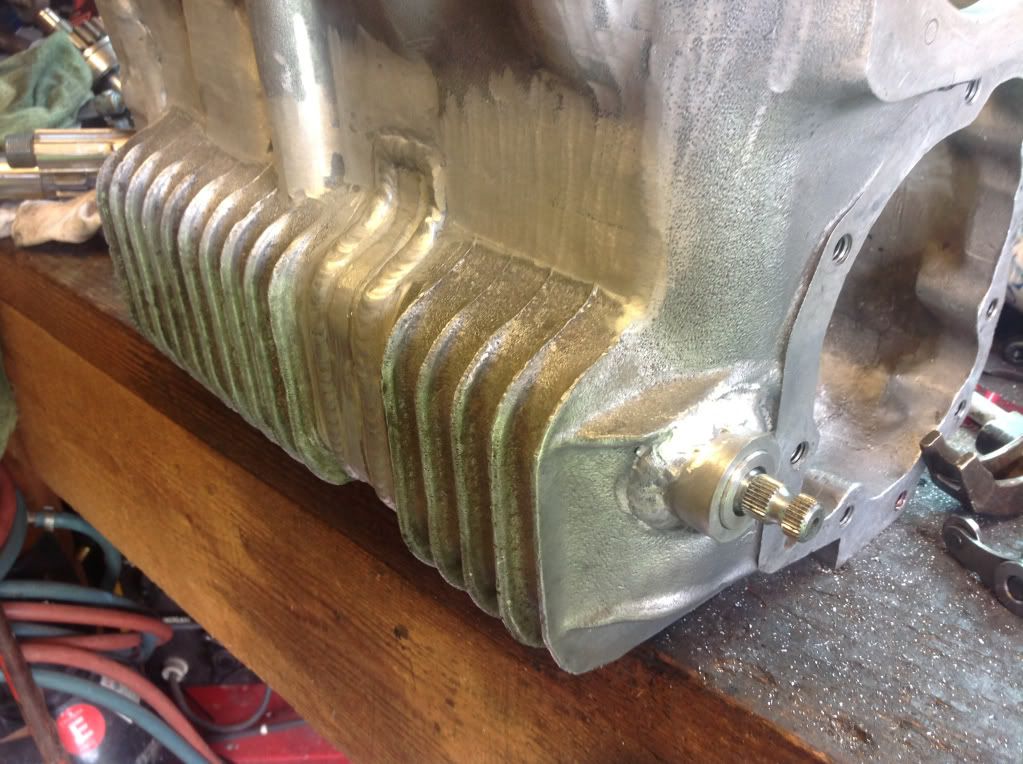

Righty bearings all sorted now.:)

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

11th Jun, 2013 at 10:43:37am

Good progress, good pics Matt!

|

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

11th Jun, 2013 at 01:52:02pm

Matty,

On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

11th Jun, 2013 at 05:48:23pm

Bart - yep you're correct, if it was mounted directly below the drum their could shift down but not up, by moving it round 10-15mm it's got enough room for shifting

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

299 Posts Member #: 2814 Senior Member Mansfield - Notts |

11th Jun, 2013 at 06:24:57pm

This is brilliant, hats off to you Matty. I bet it's so frustrating refitting then removing the gearset everytime. It looks brilliant thou man, it'll all be worth it I'm sure! |

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |