| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

28th Jan, 2013 at 11:44:22am

Hi Matt, that thrustring from hell will function well to keep your shaft properly located. Do you also consider making oval grooves in it for lubrication like the original mini idler gear shim has?

Edited by Streetscreamer on 28th Jan, 2013. |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

28th Jan, 2013 at 12:50:47pm

yeah im going to file some grooves into the thrust face, but i need to face it again once its been soldered in. im still working out how to sort the thrust in the opposite direction. but i can't see it being too much of an issue. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

29th Jan, 2013 at 09:59:24pm

Bush with larger face? Only horrible to have it sorted out with a proper play. I guess you don't want to have a pile of shims between the bushes and have it all torqued up to 150 Nm-ish. squeeezzzzzz... |

||||||

380 Posts Member #: 1835 Senior Member Thame, oxfordshire |

2nd Feb, 2013 at 08:27:40pm

looking good mate! havent logged on in a while, looks like its coming along really well!?! On 23rd Aug, 2010 Nic said:

Turbophil had a butt plug made that seemed to be suitable. He may have finished with it now and have it kicking around spare |

||||||

|

76 Posts Member #: 9204 Advanced Member Amsterdam...Edinburgh |

3rd Feb, 2013 at 03:44:44pm

This is freaking amazing......i was going into Woods after the first few pages.....

|

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

7th Feb, 2013 at 12:09:01pm

amazing matty!! Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

7th Feb, 2013 at 10:06:34pm

On 2nd Feb, 2013 dan_up said:

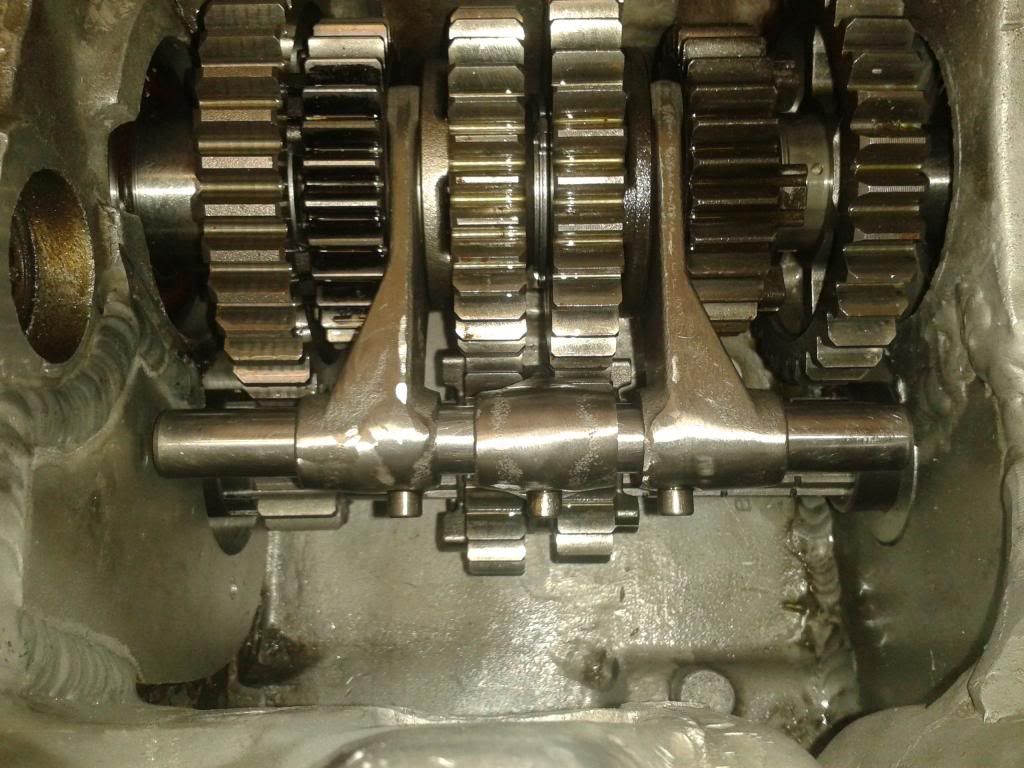

looking good mate! havent logged on in a while, looks like its coming along really well!?! Cheers, mate long time no see! Yours must be finished by now? Thanks for the comments. Progress has been slow (lack of time), but during my lunch hour I have managed to get a few things done. The selector drum now fits in and the forks are finished, I now have the position of where to drill, so its back on the mill for some drilling!

I have also started blending the 'added plates' into the box, and smoothing out the casting masks inside and outside of the box. pics...

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

380 Posts Member #: 1835 Senior Member Thame, oxfordshire |

7th Feb, 2013 at 11:32:03pm

On 7th Feb, 2013 matty said: yeah been a while! haha you would have thought so! i've been neglecting it again, i was up there last weekend, its geting there very slowly.

On 2nd Feb, 2013 dan_up said:

looking good mate! havent logged on in a while, looks like its coming along really well!?! Cheers, mate long time no see! Yours must be finished by now? Lots of nice work going on with yours though, havent seen it since MITP 2010?! you got access to some nice machines with the new job?!? i say new, probably been there a while now? On 23rd Aug, 2010 Nic said:

Turbophil had a butt plug made that seemed to be suitable. He may have finished with it now and have it kicking around spare |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

13th Feb, 2013 at 08:06:47pm

HI Matt,

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

13th Feb, 2013 at 09:47:31pm

Haha yeah have access to some nice machines, but they've always got something else on them so never get to use them for my own stuff. lol On 7th Feb, 2013 dan_up said:

On 7th Feb, 2013 matty said: yeah been a while! haha you would have thought so! i've been neglecting it again, i was up there last weekend, its geting there very slowly.

On 2nd Feb, 2013 dan_up said:

looking good mate! havent logged on in a while, looks like its coming along really well!?! Cheers, mate long time no see! Yours must be finished by now? Lots of nice work going on with yours though, havent seen it since MITP 2010?! you got access to some nice machines with the new job?!? i say new, probably been there a while now? I haven't fixed them in place yet. But i generally sandblast the silver solder away so you're only left with a small fillet. The smoothing of the box, is partly tidy it up but mainly to stress releive it by removing any sharp edges. The last thing I'd want is for it to crack along one of the casting marks.

Im not 100% on the shifter mech, but I think I can get the VFR one to work. I'll know once I get the holes drilled and everything lined up in its correct place.

On 13th Feb, 2013 Streetscreamer said:

HI Matt, I'm curious how you finally fixed the dowels top the forks, as I can't see any sign of soldering. Or was that "evidence" polished away? And why the smoothingof the internal side of the box: will you finally polish it for good show?

Good luck with last drilling. Curious what gear shift spindle system you will use. Mine will be a blend of VFR800 and home-brew connection to a star of the kawa z900 regards, Bart https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6549 Posts Member #: 1149 #1 Basshunter Fan Force Racing ICT Dept Manager Miglia Turbo Am frum Yokshyer tha noes! |

14th Mar, 2013 at 03:13:43pm

Any updates on this Matty? 1/4 Mile 14.3secs 96Mph Terminal 10psi of boost.

|

||||||

88 Posts Member #: 720 Advanced Member Gloucestershire |

14th Mar, 2013 at 06:30:19pm

Epic project - hats off to you :) |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

14th Mar, 2013 at 08:30:09pm

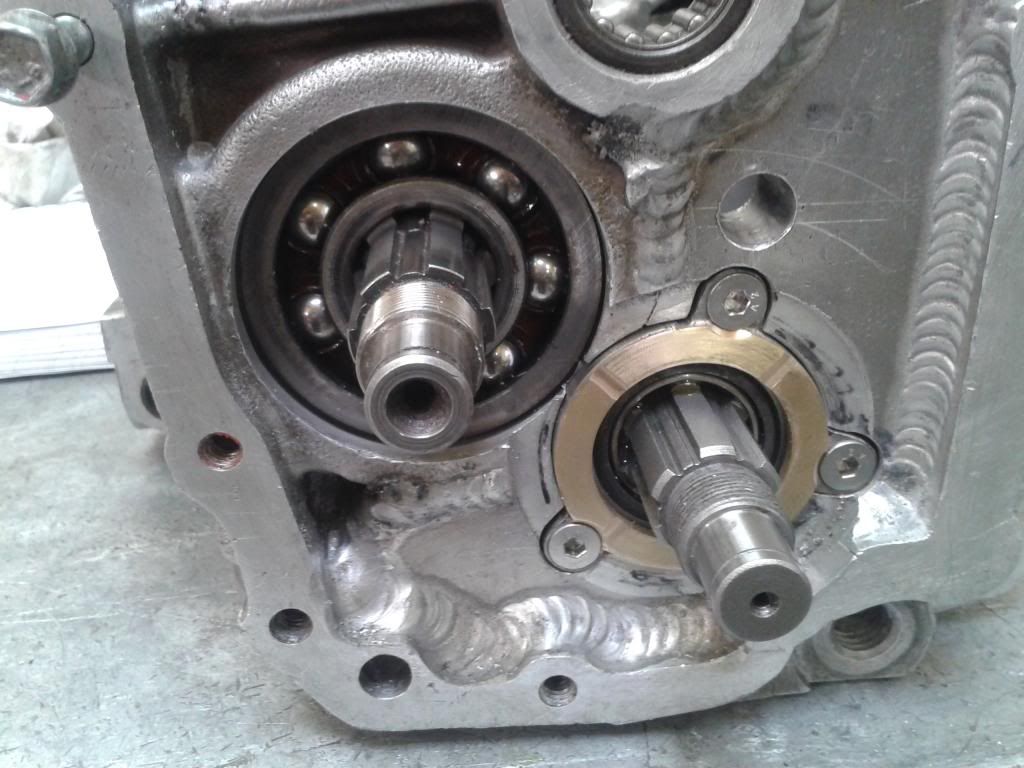

Urm a slight update... The bearing retainer is all finished now, the selector drum machined down, and the holes drilled in the box for the selector shaft. My gear for reverse has also arrived but there's a slight problem with that! Lol

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

412 Posts Member #: 9766 Senior Member Warwickshire |

14th Mar, 2013 at 09:17:26pm

Can't wait to see this done, well done for sticking with it mate Avon 2010 class c 3rd

|

||||||

|

8215 Posts Member #: 90 Post Whore Somewhere around Swindon |

14th Mar, 2013 at 09:23:32pm

Good to hear your sticking with it Matty Crystal Sound Audio said:

Why wolfie...you should have your name as Fuckfaceshithead ! "A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools."-Douglas Adams |

||||||

|

1909 Posts Member #: 9764 Post Whore Northamptonshire. |

14th Mar, 2013 at 11:09:25pm

Gear box is looking good!! |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

15th Mar, 2013 at 11:36:54am

hurry up and finish it, I'll give you ú500 for it Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

15th Mar, 2013 at 09:45:17pm

You can have 2 for that price! :)

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

412 Posts Member #: 9766 Senior Member Warwickshire |

15th Mar, 2013 at 10:31:00pm

Amazing! Avon 2010 class c 3rd

|

||||||

1849 Posts Member #: 672 The oversills police Oslo, Norway |

17th Mar, 2013 at 12:51:31pm

good stuff! I am worried that lower bearing will suffer from contaminated oil, as there is no good drains down low for the oil that comes down from the outside of the main bearing and that area anymore. will oil with crap in it be left laying there? |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

17th Mar, 2013 at 04:29:52pm

That's a good point I hadn't thought about that! https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

17th Mar, 2013 at 07:35:52pm

Hi Matt,

|

||||||

|

61 Posts Member #: 9748 Advanced Member Bedfordshire |

25th Mar, 2013 at 05:10:40pm

very impressive! this thread alone has now given me the motivation to continue to learn how to use my dads machinery!

|

||||||

4890 Posts Member #: 1775 Post Whore Chester |

25th Mar, 2013 at 09:15:47pm

That bearing retainer has given me the horn. I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

7th May, 2013 at 09:55:46pm

Well it's been a while, but I've been tickling away on this during my lunch breaks at work. It's nearly all in, just waiting for a few bearings to turn up, then i can position the shift each, and sort reverse out.

Edited by matty on 7th May, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |