| Page: |

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

16th Jan, 2013 at 07:11:30pm

I managed to build the gearbox up today, which didn't seem as fidly as I'd imagined, but at least I know it can all be built up inside the casing now.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

16th Jan, 2013 at 07:13:47pm

Still lots to squeeze in there! On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

16th Jan, 2013 at 07:17:56pm

Wowsers! Is the drum higher than the centre web? It's hard to see from the pic.

In the 13's at last!.. Just |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

16th Jan, 2013 at 07:28:22pm

I think its level with the radius on the top of the centre web...from what I remember it sat about 10mm above the oil pick up bracket. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6745 Posts Member #: 828 Post Whore uranus |

16th Jan, 2013 at 07:38:27pm

bring it over matt and we could plonk a block and crank on it and see? Medusa + injection = too much torque for the dyno ..https://youtu.be/qg5o0_tJxYM |

||||||

6549 Posts Member #: 1149 #1 Basshunter Fan Force Racing ICT Dept Manager Miglia Turbo Am frum Yokshyer tha noes! |

16th Jan, 2013 at 07:54:53pm

Jealously is a cruel mistress 1/4 Mile 14.3secs 96Mph Terminal 10psi of boost.

|

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

16th Jan, 2013 at 08:17:25pm

Now that is looking goog |

||||||

|

4314 Posts Member #: 700 Formerly British Open Classic The West Country |

16th Jan, 2013 at 09:14:28pm

Looking really good, I've enjoyed following this build massively.

Isambard Kingdom Brunel said:

Nothing is impossible if you are an Engineer |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

16th Jan, 2013 at 09:49:27pm

On 16th Jan, 2013 robert said:

bring it over matt and we could plonk a block and crank on it and see? Cheers for the offer Robert, ive got my block stripped down so I can check it if needs be. I might put some parallels between the block and box so I can look and see how close it will be. Moving the dowels might make it easier to fit in after looking at it again. Im finally getting round to using your box you let me borrow about a year ago!

Thanks for all the comments, ive got my motivation back on this now so i'll hopefully be updating the build more regularly. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

6549 Posts Member #: 1149 #1 Basshunter Fan Force Racing ICT Dept Manager Miglia Turbo Am frum Yokshyer tha noes! |

16th Jan, 2013 at 11:04:06pm

Matt could you not come outside the box using the outlet where the blanking plate normally goes, then route it left and back in? 1/4 Mile 14.3secs 96Mph Terminal 10psi of boost.

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

16th Jan, 2013 at 11:19:12pm

This thread makes me feel like a total noob at fucking about with cars. Serious envy! turbo 16v k-series 11.9@118.9 :)

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

17th Jan, 2013 at 06:30:20pm

On 16th Jan, 2013 MikeRace said:

Matt could you not come outside the box using the outlet where the blanking plate normally goes, then route it left and back in? I think im going to redrilll the pick up pipe at the pinion end, and route the pipe on the outside of the box where the blanking plate usually is. Denis - It really isn't all that difficult to do, just time consuming.

Ive decided to move the dowels on the selector forks now to lower the heigth of it so that may help gain a bit of space. I made a jig up to hold them all in line, so when I redrill them they all line up on the selector drum in the same place.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

17th Jan, 2013 at 06:38:11pm

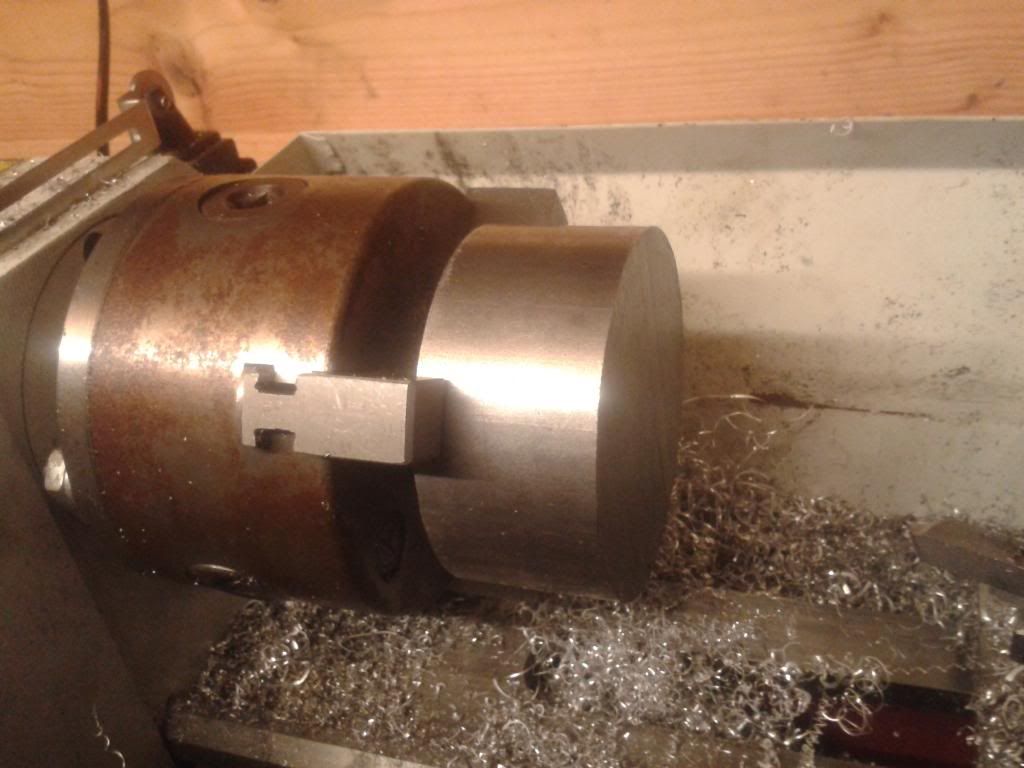

I had the shaft ground down today .02mm over size, then I gently heated the hardened sleeve up and tapped it over the shaft.

https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

2057 Posts Member #: 9252 Post Whore Cleethorpes |

17th Jan, 2013 at 07:28:42pm

great build looking forward to see the final results Done now needs redoing lol |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

21st Jan, 2013 at 09:08:50pm

Hi Matt,

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

21st Jan, 2013 at 10:40:31pm

Hi Bart, yeah ive got that star indexing bit, but im still deciding which side of the web to mount that on. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

509 Posts Member #: 1027 Post Whore Germini, black forrest |

22nd Jan, 2013 at 10:22:03am

Wow. That's all my blown mind is able to express right now... :)

[X] nail here for new monitor |

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

23rd Jan, 2013 at 09:40:06pm

Hi Matt,

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

23rd Jan, 2013 at 10:22:27pm

I managed to drill my selector forks so hopefully it won't be too long before I can decided whether there is room or no for the selector mechanism on the drum side. I am looking at maching the drum down to make some more room.

Edited by matty on 23rd Jan, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

23rd Jan, 2013 at 11:25:08pm

Poor gears...... hope it won't delay you too much and loosing the momentum you have again.

|

||||||

580 Posts Member #: 9580 Post Whore Surrey |

24th Jan, 2013 at 06:10:16am

Good skills as ever |

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

26th Jan, 2013 at 06:17:50pm

Woohoo my new gear for my lathe arrived today, neatrly finished the lathe rebuild. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

112 Posts Member #: 10125 Advanced Member Zoetermeer, The Netherlands |

26th Jan, 2013 at 10:33:40pm

OK, curious for your findings. At least the heart-heart distance is 5 mm less some that might give you the right space.

|

||||||

8297 Posts Member #: 408 Turbo Love Palace Fool Aylesbury |

27th Jan, 2013 at 10:37:24pm

Ah there is a part I might need (not 100% certain yet though) and thats the thrust washer with locking plate on the input shaft? To be honest that 5mm could make all the difference of it fitting in and being able to use the original mechanism. Edited by matty on 27th Jan, 2013. https://www.facebook.com/pages/Fusion-Fabri..._homepage_panel

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

27th Jan, 2013 at 10:45:16pm

nice! |

||||||

| Home > Show Us Yours! > K1100 16V Turbo build...now transmission build. | |||||||

|

|||||||

| Page: |

I handed over my design last week to the contacts to produce. Just on small details there is difference (choice of spline type etc) but generally the same.

I handed over my design last week to the contacts to produce. Just on small details there is difference (choice of spline type etc) but generally the same.