| Page: |

| Home > Show Us Yours! > Electric waterpump project | |||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

3rd Nov, 2013 at 04:53:59pm

On 3rd Nov, 2013 Joe C said:

LOL looks a bit heavy duty Paul, you going to drive the alternator off it too? LOL - perpetual motion Eh ? It's actually a starter motor from a Toyota and identical to the motor on the Mini high torque starter, bottom left of picture. Plenty of revs and wattage :) Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

270 Posts Member #: 69 Senior Member Coventry |

3rd Nov, 2013 at 10:58:30pm

Very interesting thread. It isnt unussual to find lumps of sand casting crap in the waterways and 30 years of crude build up. The Hi Torque Starter does indeed look exactly like a Toyota one, which is a Denso starter, a separate thread might be useful to find out or work out which one and whats required to make which ever is the best Denso Starter onto a mini. If you could pick up a used Toyota Starter and someone did a alloy adaptor plate and drive gear that could be a cracking little MOD. So Evans is basically snake oil...

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

4th Nov, 2013 at 06:42:33am

has anyone ever done what paul has taken a pic of

|

||||||

7765 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

4th Nov, 2013 at 04:20:06pm

On 23rd Oct, 2013 Turbo Phil said:

I did this years ago when I had a front mounted rad, though I never dyno'd the engine it made a noticeable difference to engine response. Phil. I agree. I removed the fan (not pump) and think I could feel the difference.... On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

4th Nov, 2013 at 05:46:52pm

On 4th Nov, 2013 Turbo This.. said:

has anyone ever done what paul has taken a pic of that is drive the std mini pump with an electric motor via the correct size pulleys and or a viable speed motor? I'd have thought it'd actually be an easy way of determining the power used by the waterpump (and fan); either with the motor current consumed, or by some kind of load-cell applied to a torque-arm on the motor mount or idler... But I imagine Paul is already one step ahead. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

270 Posts Member #: 69 Senior Member Coventry |

5th Nov, 2013 at 12:08:42am

http://www.shengineering.co.uk/sh/sites/de...ts/DSCF0571.JPG From SH website, huge water pump pulley and Crank Pulley... Reason? perhaps by increasing pulley diameter the amount of surface area of belt in contact with pulleys will stop it slipping?? or is there other thoughts? |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

5th Nov, 2013 at 02:16:51am

I'd have thought they have some new crank damper with a large diameter housing needing a big pulley, but didn't want the water pump turning at 12000 RPM. It does look odd though.

Edited by TurboDave16V on 5th Nov, 2013. On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

|

248 Posts Member #: 7936 Senior Member DK-8450 Hammel. Denmark |

5th Nov, 2013 at 05:10:58am

I think only 2 bolts have been tightend. If i have more toys than you when i die, I WIN |

||||||

|

336 Posts Member #: 9941 Senior Member Derby |

5th Nov, 2013 at 07:54:53am

The idea of that pulley must be for the likes of 16v minis that are revving to 10k I'd have thought |

||||||

690 Posts Member #: 1851 Post Whore Woolavington, Zummerzet |

5th Nov, 2013 at 10:04:56am

Utterly non-scientific, but the two engines I've fitted Dowty fans to felt like they revved up and down faster than with a std fan.

Metric is for people who can't do fractions. |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

5th Nov, 2013 at 04:56:18pm

On 5th Nov, 2013 jamiestevenbell said:

The idea of that pulley must be for the likes of 16v minis that are revving to 10k I'd have thought Why design it to clear the 5 port head then?

On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

6th Nov, 2013 at 08:58:50am

my thinking is that that ratio of pulleys for engines spending there life at like 7-10K and thats slowing the fan and pump to the point where they come back into there efficiency range |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

6th Nov, 2013 at 10:47:01pm

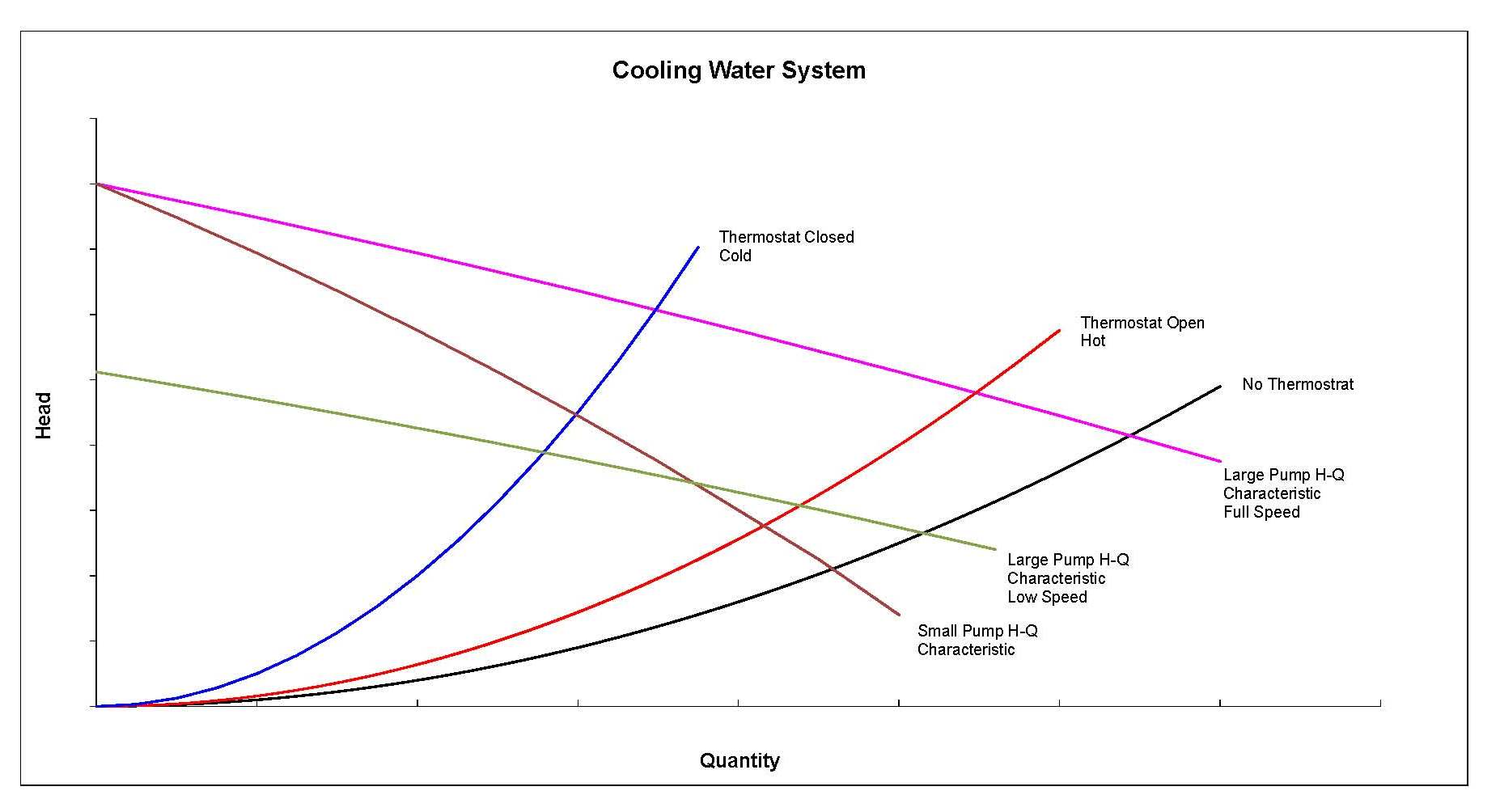

what about using the smaller impellor pump instead of the larger one?

On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

7th Nov, 2013 at 05:26:05pm

I don't think that the choice of pump would help much other than to limit the maximum flow.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

326 Posts Member #: 1323 Senior Member |

7th Nov, 2013 at 08:58:01pm

I used a Corley Conversion pump on my KAD engine in the early 90's

|

||||||

|

224 Posts Member #: 9987 Senior Member Amsterdam |

5th May, 2014 at 04:10:37pm

So....I got taken over by work the past few months therefore it has taken me a while to get back with any significant updates.

|

||||||

324 Posts Member #: 9441 Senior Member South Devon |

5th May, 2014 at 06:10:25pm

Sorry if it's already been mentioned but does the pump controller also switch on the fan or is that on it's own thermostat? |

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

5th May, 2014 at 06:19:25pm

i like that rocker cover :) Yes i moved to the darkside |

||||||

|

224 Posts Member #: 9987 Senior Member Amsterdam |

5th May, 2014 at 06:20:37pm

The controller activates both pump and fan, it is able to modulate pump voltage between zero (completely off) and anywhere between 6volt and 13volt.

Edited by Evoderby on 5th May, 2014. |

||||||

2742 Posts Member #: 637 Post Whore Hertfordshire |

27th Jan, 2017 at 10:22:49pm

Old post revival!

My build thread..

|

||||||

36 Posts Member #: 262 Member Netherlands |

9th Mar, 2017 at 09:12:42am

And did you ever dyno it to see how many ponies you saved? Op de bank beleef je geen avonturen |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

7th Feb, 2018 at 03:30:56pm

On 1st Nov, 2013 Paul S said:

A 2-core radiator is really struggling with over 30kW of heat. I've got datalogs from a 100mph cruise on our test track. Engine sat at around 94 Deg C on a cool day in October 2010 on the way back from the RR day. Plugging that into the calcs and allowing for a top end performance from the rad, then it just about copes with 35kW. It would not be happy on a hot day. On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

7th Feb, 2018 at 06:06:06pm

From the sims, I was seeing heat given off by the intercooler equivalent to about 10% of brake power. That's based on 20 DegC ambient, 85% Efficiency cooler.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

7th Feb, 2018 at 06:23:03pm

Cool, so about 15-20 kW ball park, that should work. On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

| Home > Show Us Yours! > Electric waterpump project | |||||||

|

|||||||

| Page: |

The electronic waterpump controller modulates the pump perfectly to a fast warm up, after which it uses full power and if necessary fan assist to keep a stable temp, even when idling for longer periods.

The electronic waterpump controller modulates the pump perfectly to a fast warm up, after which it uses full power and if necessary fan assist to keep a stable temp, even when idling for longer periods.