| Page: |

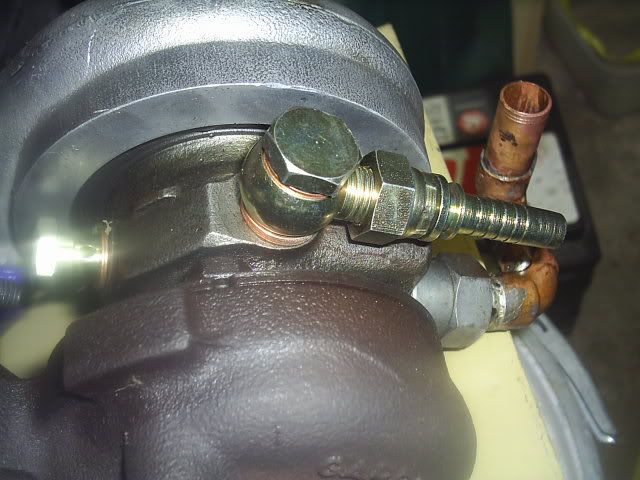

| Home > Show Us Yours! > T2 water connectons and Oil Drain | |||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

19th Nov, 2005 at 04:31:01pm

Had quite a productive day in the garage.. |

||||||

|

Forum Mod 10980 Posts Member #: 17 ***16*** SouthPark, Colorado |

19th Nov, 2005 at 05:19:59pm

Next job is the actuator i'm guessing? On 17th Nov, 2014 Tom Fenton said:

Sorry to say My Herpes are no better Ready to feel Ancient ??? This is 26 years old as of 2022 https://youtu.be/YQQokcoOzeY |

||||||

9317 Posts Member #: 59 First mini turbo to get in the 12's & site perv Herefordshire |

19th Nov, 2005 at 05:20:16pm

nice!

|

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

19th Nov, 2005 at 05:35:42pm

yep actuator is next, finally the list of jobs is getting smaller |

||||||

|

Forum Mod  1322 Posts Member #: 28 Post Whore Milton Keynes |

19th Nov, 2005 at 06:04:04pm

Pirteck hose's had the correct banjo's for my t25, but they had to be specially ordered and in total cost me about 40quid! grrrr |

||||||

|

Forum Mod  4828 Posts Member #: 154 Post Whore Midlands |

19th Nov, 2005 at 10:16:57pm

yeah we went to pirtek first to try and get some, but no joy. ended up going to the place i got my fuel return T piece from and only cost about a tenner i think.

On 20th Oct, 2015 Tom Fenton said:

Well here is the news, you are not welcome here, FUCK OFF. |

||||||

6274 Posts Member #: 509 Post Whore Isle of Man |

1st Dec, 2005 at 02:44:54pm

just a quickie, are you not worried about the solder when the turbo gets hot?

"Turbo's make torque, and torque makes fun"

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

1st Dec, 2005 at 03:06:21pm

yeah, i was wondering about the solder too, ordinary solder melts at about 215 C.

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

9812 Posts Member #: 332 Resident Cylinder Head Modifier Mitsi Evo 7, 911, Cossie. & all the chavs ...... won no problem |

1st Dec, 2005 at 06:16:08pm

clubby i hope iam not a pain it the rear but....... them copper joints will fail you!

|

||||||

2521 Posts Member #: 417 Post Whore Swindon |

1st Dec, 2005 at 08:04:58pm

I've seen two std blue ones joined together with a sleeve before on a T2

|

||||||

7765 Posts Member #: 74 I pick holes in everything.. Chief ancient post excavator |

2nd Dec, 2005 at 08:26:17am

The water in the pipes will never be much more than 100deg C will they? I guess the solder will be OK. Thermotec them.... Easy! On 13th Jul, 2012 Ben H said:

Mine gets in the way a bit, but only when it is up. If it is down it does not cause a problem. |

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

2nd Dec, 2005 at 02:00:33pm

I was hoping they shouldnt get that hot be honest,

Edited by Kean on 2nd Dec, 2005. |

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

2nd Dec, 2005 at 02:11:23pm

From the info I can find, the solder I used has a melting point of 227 degrees C

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

2nd Dec, 2005 at 03:28:19pm

I reckon that'll be a problem, I don't know how hot the oill draining out the turbo is but I'd say HOT, plus the fact the pipe is solidly connected to the turbo (no thermal barrier). The main thing is if it does let go it'll probably be at the worst possible time. also there's the possible fire risk of oil getting on a hot turbo.

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

9317 Posts Member #: 59 First mini turbo to get in the 12's & site perv Herefordshire |

2nd Dec, 2005 at 05:09:37pm

i measured 300 and something on my manifolds, id change for 13mm steel pipe and get it tig-ed |

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

2nd Dec, 2005 at 05:33:09pm

right, thanks for the input guys....... back to the garage lol

|

||||||

|

Forum Mod  4828 Posts Member #: 154 Post Whore Midlands |

2nd Dec, 2005 at 06:17:22pm

i thought it was all going a little too easy On 20th Oct, 2015 Tom Fenton said:

Well here is the news, you are not welcome here, FUCK OFF. |

||||||

9812 Posts Member #: 332 Resident Cylinder Head Modifier Mitsi Evo 7, 911, Cossie. & all the chavs ...... won no problem |

2nd Dec, 2005 at 08:38:44pm

clubby like i said i dont mean to be a pain up the thruster but......

|

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

2nd Dec, 2005 at 08:56:28pm

Yes I agree Benross, the last thing I want is solder flying through my engine, along with no oil pressure and a turbo on fire lol..

|

||||||

6274 Posts Member #: 509 Post Whore Isle of Man |

5th Dec, 2005 at 05:26:40pm

yeah, i wouldnt take the chance to be honest, turbos dont come cheap :)

"Turbo's make torque, and torque makes fun"

|

||||||

|

Forum Mod  4828 Posts Member #: 154 Post Whore Midlands |

9th Dec, 2005 at 12:37:31pm

can anyone see a problem using normal plumbing compression joints? On 20th Oct, 2015 Tom Fenton said:

Well here is the news, you are not welcome here, FUCK OFF. |

||||||

|

397 Posts Member #: 694 Senior Member Shropshire |

30th Sep, 2006 at 12:17:45pm

Sorry its an old thread i know.

|

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

30th Sep, 2006 at 04:19:37pm

The main problem with using the existing entry into the block is that its so close to the turbo... you can just get it, but its tight messy..

|

||||||

|

93 Posts Member #: 1212 Advanced Member braintree, essex |

15th Oct, 2006 at 07:03:48pm

compression joint are what oil boilers have to use so they would be fine. u can buy chrome ones too. |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

15th Oct, 2006 at 10:18:30pm

you have two easy options as I see it, do as I did and tig weld a pipe into the gearbox casing, or simpler:

Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

| Home > Show Us Yours! > T2 water connectons and Oil Drain | |||||||

|

|||||||

| Page: |