| Page: |

| Home > Technical Chat > Exhaust manifold pressure reading | |||||||

|

283 Posts Member #: 8215 Senior Member Rayleigh |

25th Feb, 2015 at 05:14:16pm

So I've been speaking to a Chris from chris isaacs race cars about my custom manifold.

Dave the Cake |

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

25th Feb, 2015 at 09:19:36pm

compression fitting(or similar) in exhaust, length of metal pipe so the gasses can cool down a bit (remember theres no flow just pressure so you dont need to go nuts) then normal hose and a suitable pressure transducer.

Edited by evolotion on 25th Feb, 2015. turbo 16v k-series 11.9@118.9 :)

|

||||||

293 Posts Member #: 10010 Senior Member Northants |

25th Feb, 2015 at 10:10:22pm

On a similar note, I would like to measure exhaust pressure on our Formula Student car, as it will be running a turbocharged single cylinder, and I'm interested in the effect of the single pulses on turbo speed.

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

25th Feb, 2015 at 10:27:43pm

Use a transducer thats rated to a very high temp and a nice short metal line? turbo 16v k-series 11.9@118.9 :)

|

||||||

|

283 Posts Member #: 8215 Senior Member Rayleigh |

26th Feb, 2015 at 12:42:11am

Humm I really don't know, he definitely said to take the reading from the collector. He seems like a very knowledgable bloke and I didn't understand all of what he said.

Dave the Cake |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

26th Feb, 2015 at 09:10:05am

What you would actually be measuring is the turbine inlet pressure.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

26th Feb, 2015 at 11:38:10am

Similar bit of pipe to Paul's, for the same reason, and also waiting to be installed...

Schrödinger's cat - so which one am I ??? |

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

26th Feb, 2015 at 12:30:54pm

On 25th Feb, 2015 Custard said:

So I've been speaking to a Chris from chris isaacs race cars about my custom manifold. I asked how to find out if it's restricting power and he said I need to monitor the back pressure in the manifold before the turbo. Does anyone do this? If so what have you used? He said the EMAP should rise fairly evenly with the boost, and obviously if it gets a lot more then it's becoming restrictive. Cheers What is the design, application and expected power output ? And the longish line used to allow exhaust gases to cool slightly before the sensor will have negligible effect on the readings And in most cases, the turbine/housing is the main restriction anyway, so even horrific looking manifolds can make huge power. 9.85 @ 145mph

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

27th Feb, 2015 at 10:54:31am

i was shocked to look down the metro t3 and see like a 15mm hole that the engine must breath threw instantly thought how the heck will this make power pushing the exhaust past that then i thought well its only going to flow threw there till its at full boost then it gets bypassed in the waste gate so not all that bad really but defiantly the biggest restriction to bulk flow in the whole exhaust system |

||||||

|

Site Admin  15300 Posts Member #: 337 Fearless Tom Fenton, Avon Park 2007 & 2008 class D winner & TM legend. |

27th Feb, 2015 at 11:12:45am

As said above, its the turbo that is going to cause the restriction as long as the manifold is something like sensible. But I think measuring the back pressure in the manifold is still a useful exercise, it could maybe point you towards running a slighly "larger" turbo at less boost pressure to make the same power for e.g.

On 29th Nov, 2016 madmk1 said:

On 28th Nov, 2016 Rob Gavin said:

I refuse to pay for anything else Like fuel 😂😂 |

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

27th Feb, 2015 at 11:59:09am

On 27th Feb, 2015 Turbo This.. said:

i was shocked to look down the metro t3 and see like a 15mm hole that the engine must breath threw instantly thought how the heck will this make power pushing the exhaust past that then i thought well its only going to flow threw there till its at full boost then it gets bypassed in the waste gate so not all that bad really but defiantly the biggest restriction to bulk flow in the whole exhaust system And a metro T3 is huge by modern standards, in every respect When you compare it to modern units that are capable of 150-200hp, including diesels etc...it's huge ! There is no doubt that manifold design, tube sizes etc can affect many aspects of performance, but from an outright ability to make power...almost anything will work. I know it's at the comical end...but check out the "sloppy mechanics" guys. Yes some of it is laughable...but bare in mind it's all very much cheap DIY, they use junkyard engines for a few hundred dollars and chinese turbos etc And most go remarkably fast for very very little money ! And some of that isnt even the worst I've seen LOL http://sloppymechanics.blogspot.co.uk/2013...hung-turbo.html 9.85 @ 145mph

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

27th Feb, 2015 at 05:52:24pm

Any combination of pipes will "work", but if you want the most power for a given boost, then the design needs to be pretty precise.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

27th Feb, 2015 at 06:05:03pm

on the subjecto of manifold fabbing this series of vids is quite useful,

On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

|

283 Posts Member #: 8215 Senior Member Rayleigh |

28th Feb, 2015 at 08:53:10pm

Thanks for all the replies!

Dave the Cake |

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

28th Feb, 2015 at 09:55:24pm

There is no way ever that would restrict power on an A-series.

9.85 @ 145mph

|

||||||

|

283 Posts Member #: 8215 Senior Member Rayleigh |

28th Feb, 2015 at 10:27:54pm

Fair enough :) Dave the Cake |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

28th Feb, 2015 at 10:44:13pm

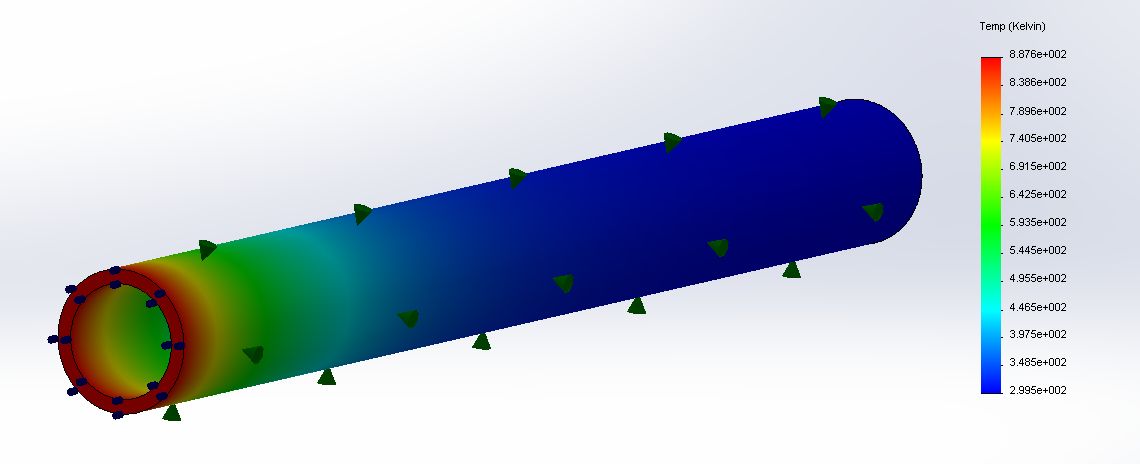

Pipes are too large on diameter and too short in length for maximum power.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

28th Feb, 2015 at 11:40:06pm

Makes sense Paul and I understand you've got the simulations to back it up. But 95% of OEM manifolds are short, uneven lengths - is it really so bad?

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

1st Mar, 2015 at 09:41:19am

No, it's not bad just not the best way to do it, particularly with the 5-Port.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

1st Mar, 2015 at 10:14:10am

On 28th Feb, 2015 Custard said:

From memory they are 1 1/2" pipes On 28th Feb, 2015 Paul S said:

Pipes are too large on diameter and too short in length for maximum power. Just saying. On 1st Mar, 2015 Paul S said:

If you are putting the turbo at the back of the engine, then the 38mm/1 1/2" pipe is best because it creates low amplitude pulses that do not have too much negative impact.

On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

1st Mar, 2015 at 11:04:25am

On 28th Feb, 2015 Paul S said:

Pipes are too large on diameter and too short in length for maximum power. Just saying. I'm sure cam profile, head design, exhaust design, intake design, turbocharger etc are also not best for "maximum" power.. And with approx 150hp build...clearly "maximum" power isnt the ultimate goal. As with OEM and many builds, maximum power is really the least of the considerations. Spool, spread of torque, power delivery etc are all more important, simply because actually making good power is the easiest bit and where the driver spends least time using. There is no need to over think things. The manifold will work just fine. 9.85 @ 145mph

|

||||||

|

696 Posts Member #: 10034 Post Whore Birmingham |

1st Mar, 2015 at 11:06:03am

So if you can't tune / lengthen the runners to make use of the pulses, then just make the pipe large enough that it has no +ve or -ve effect ?

Edited by PhilR on 1st Mar, 2015. |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

1st Mar, 2015 at 11:06:07am

haha,

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

1st Mar, 2015 at 01:50:51pm

Measuning exhaust pressure on its own is meaningless. You neet to compare it to inlet manifold pressure. This gives you engine pressure ratio. Anything above 1:3 is considered poor, while 1:1 is excellent and achievable, it requires careful consideration of complete engine design. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

9258 Posts Member #: 123 Post Whore Betwix Harrogate and York |

1st Mar, 2015 at 04:32:36pm

Isn't that what that nut-job Mini1071 used to bang on about?

On 1st Mar, 2015 Sprocket said:

Measuning exhaust pressure on its own is meaningless. You neet to compare it to inlet manifold pressure. This gives you engine pressure ratio. Anything above 1:3 is considered poor, while 1:1 is excellent and achievable, it requires careful consideration of complete engine design. Fastest 998 mini in the world? 13.05 1/4 mile 106mph

On 2nd Jan, 2013 fastcarl said:

the design shows a distinct lack of imagination, talk about starting off with a clean sheet of paper, then not bothering to fucking draw on it,lol On 20th Apr, 2012 Paul S said:

I'm mainly concerned about swirl in the runners caused by the tangential entry. |

||||||

| Home > Technical Chat > Exhaust manifold pressure reading | |||||||

|

|||||||

| Page: |