| Page: |

| Home > A-Series EFI / Injection > Microsquirt V3 usage | |||||||

|

17 Posts Member #: 10920 Member West of Ireland |

7th Aug, 2014 at 09:27:00am

Hello all

Mini => Money Is Not Important

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

7th Aug, 2014 at 02:26:56pm

On 7th Aug, 2014 Coolmini said:

Can the microsquirt v3 ecu do sequencial injection with staging. Basically no. The Microsquirt as it stands only has two injector chanels so, by definition you can't have both sequential and staged as that requires 4 chanels. We can do it with an MS2 (which in normal form is also only 2 chanels) because there is a well documented modification to the daughterboard, supported by the MS2-Extra code, to make it 4 chanels and the siamese sequential part of that code allows staged sequential, and we add all the extra hardware to support 4 chanels. It "may" be that the CPU inside the Microsquirt case has an additional 2 chanels available as it is the same processor and very similar firmware to the MS2 - hopefully Jean will see this thread and answer - but it most definately isn't intended to be that way as the assembled MicroSquirt isn't meant to be DIY to add extra hardware inside the case like the MS2, it is built/sold "complete" to avoid DIY. See page 42 of the manual http://www.msextra.com/doc/pdf/Microsquirt...e_Guide-3.3.pdf EDIT - grammer and link added Edited by Rod S on 7th Aug, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

7th Aug, 2014 at 04:12:27pm

You mention the Microsquirt V3 and you also mention the Microsquirt module. I don't know if you're aware of this but these are 2 different products with different purpose and slightly different possibilities.

Edited by jbelanger on 7th Aug, 2014. |

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

7th Aug, 2014 at 07:07:28pm

thank you all for quick reply,

Mini => Money Is Not Important

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

7th Aug, 2014 at 09:35:34pm

The module is not the same board as the cased version of the Microsquirt; the module has additional pads that give access to more CPU pins and doesn't connect multiple pins to the same output (look at the schematics). The cased version cannot have more than 2 injector channels even if you open the case. You would need to make destructive modifications to the board (i.e. cut traces and/or CPU pins) and solder directly to the CPU pins to achieve this.

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

7th Aug, 2014 at 10:41:02pm

Thank you Jean for clearing that up for me.

Mini => Money Is Not Important

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

8th Aug, 2014 at 12:58:26am

Here you go: http://forum.jbperf.com/viewtopic.php?f=14...&start=20#p3693 |

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:31:59pm

Thank you again Jean,

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:31:59pm

Thank you again Jean,

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:31:59pm

Thank you again Jean,

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:34:11pm

hmm whats going on with the website here?

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:34:14pm

hmm whats going on with the website here?

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:34:17pm

hmm whats going on with the website here?

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

9th Aug, 2014 at 07:34:17pm

hmm whats going on with the website here?

Mini => Money Is Not Important

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

10th Aug, 2014 at 06:48:22am

The multiple posts seem common when people post from a phone or other mobile device.

On 9th Aug, 2014 Coolmini said:

at what stage of power is staged injection required. I got to about 96 HP with the semisequencial injection without staging. 630 cc injectors at the time NA Assuming by sequential you mean the MS2-E siamese sequential code and port injection you have to bear in mind it doesn't work like semi-sequential so the correlation between injector sizes and power output is different. The principal behind the MS2-E sequential code (it also has a semi-sequential option but let's ignore that for the moment) is to put the required fuel through an open inlet valve, not send it down the port after a valve has shut and wait for it next to open. To further confuse you there are two ways of doing this, two discrete pulses timed in sequence of valves openning or one long pulse timed at exactly the right moment when the first valve opens such that the right amount goes in both the first and second valve. What this all means, apart from timing is critical, is that the injector(s) have to be very large to be able to deliver the fuel in the "window" of open valves because the pulse widths will be tiny compared to a normal 8 port engine. In duty cycle terms a conventional engine will run injectors at 80-85%, to hit an open valve you are looking at less than 25%, more like 20% if using the discrete pulse mode because the valve opennings overlap. A while ago, Paul S and myself wrote a document describing this all in detail (search and you will find it) but to give you an idea of size vs BHP Paul got a dyno'd 115-120BHP on 880cc injection capacity and I think I have about 130BHP from 1000cc injectors (my car still isn't MOT'd yet to see a dyno so testing has been limited). Paul has moved on to MS3, I haven't built my staged injection manifold yet and Graham hasn't quite finished putting his (staged injection) engine together yet but is using 875cc for both the primary and secondary. The issue with large injectors is controlling their incredibly short pulse widths at idle, although all three of us have achieved it I would say anything larger than 1000cc (in an attempt to achieve more power without staging) would be pushing your luck. I think my idle is as good as it is is down to my 1000cc injectors being low z with a very fast open time (the others use high z but a bit smaller). EDIT - typo. Edited by Rod S on 10th Aug, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

11th Aug, 2014 at 09:04:02am

Ok Thank you again,

Mini => Money Is Not Important

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

11th Aug, 2014 at 12:59:17pm

On 11th Aug, 2014 Coolmini said:

i hope i explained that ok. I think so - I assume what you are thinking of is putting both primaries on the uS injector 1 output and both secondaries on the uS injector 2 output, then running siamese semi-sequential staged ??? Hopefully again, Jean will see this and give a definitive answer, my best answer is "possibly".... I have never used the siamese semi-sequential mode. Historically only Paul tried it (but not with staging) and with mixed results. Jean wrote the code, Paul tried it, I came in later and suggested maybe we need a cam sensor (ie, fully sequential) and Jean re-wrote the code to accomodate fully sequential with a siamese version (I think fully sequential for MS2 had always been intended, the siamese version was just the icing on the cake). That was developed into what we have now with all the individual pulse/merged pulse, timing tables, etc, everything that makes it work. The reason I say "possibly" is I've just setup a temporary project in TunerStudio on my spare MS2 in siamese semi-sequential mode and I can set staged injection, it works as expected, I still have two VE tables so presumably that will be the open valve vs closed valve difference but I only get one injector timing table (presumably open valve) so reasonably expected and the second pulse is at a fixed value. Now that probably isn't an issue as that would be the closed valve but I can't alter the fixed value and it isn't working right for my test, the grey'd out values in the setup menu don't agree with what TS shows when running. It maybe something I've done wrong, it may be a bug - bear in mind the siamese semi-sequental was never persued once Jean had added the fully sequential code - or it just may not be an issue as the value I'm getting would probably still work even though it doesn't match what the menu says. Hopefully Jean will clarify. On the point you made earlier about the cost of Jean's uS module based system compared to a plain cased uS V3, one thing I would point out is, if you go any way down the siamese sequential route, you will need additional I/O to see what the hell is going on to be able to set it up and tune it. Trust me on that, an MS2 or uS alone is not enough. Those of us following this route use Jean's IOx or IOx-OEM. Those are DIY (very DIY in the case of the IOx-OEM I use). Unless you already have something in mind particularly for data collection, or are very DIY yourself (if so you should be looking at the MS2, not the uS) Jean's package gives you pretty much everything you need rather than having to add things to the uS later. And, as I already said, Paul didn't have too much success with semi-sequential on a turbo engine, Jean's version would give you fully sequential. EDIT - typos Edited by Rod S on 11th Aug, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

11th Aug, 2014 at 02:47:18pm

The semi-sequential code is done such that it doesn't use the cam signal whether or not it is there. Since that also means the MS doesn't know which injector channel correspond to the open and closed valve, there is no trim for open and closed valve but only for channel 1 and 2 (I think, it's been a loooong time and haven't gone back to check).

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

11th Aug, 2014 at 03:30:20pm

Hi Jean,

Mini => Money Is Not Important

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

11th Aug, 2014 at 03:34:14pm

There's a build thread over at irishminis from my mini.

Mini => Money Is Not Important

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

11th Aug, 2014 at 04:12:35pm

I don't disagree that semi-sequential can work in principle but the basic history with the MS2/uS is it was tried by Paul with little success and then Jean added the cam signal for us so we didn't persue it any more.

Edited by Rod S on 11th Aug, 2014. Schrödinger's cat - so which one am I ??? |

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

11th Aug, 2014 at 04:31:51pm

If by semi-sequential you mean that you inject once per rev and that you don't have a cam signal then you can't compensate for the different VE between the inner and outer cylinders because you don't know which channel is injecting for the inner and which for the outer.

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

11th Aug, 2014 at 05:29:01pm

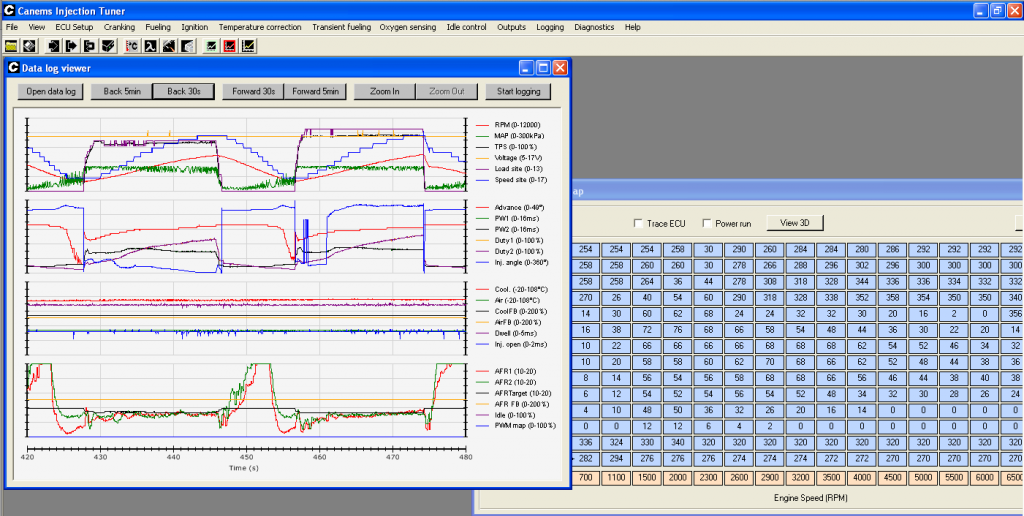

Here's the pic of canems.

Mini => Money Is Not Important

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

11th Aug, 2014 at 06:52:53pm

The injector size and pulse width will remain about the same whether you are running semi-sequential or sequential. In both cases, each channel will fire twice per cycle. In the case of semi-sequential, each injector will fire once per rev without knowing which cylinder is being fueled while in sequential, each injector is being fired twice but with the timing and fueling set for the cylinder being fueled.

|

||||||

|

17 Posts Member #: 10920 Member West of Ireland |

11th Aug, 2014 at 07:04:34pm

All Angles covered there then.

Mini => Money Is Not Important

|

||||||

| Home > A-Series EFI / Injection > Microsquirt V3 usage | |||||||

|

|||||||

| Page: |

)

)