| Page: |

| Home > A-Series EFI / Injection > DC Motor Control from ECU ??? | |||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

8th Nov, 2013 at 03:41:11pm

I need to control the speed of a 12v DC motor driving my water pump.

Edited by Paul S on 8th Nov, 2013. Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

8th Nov, 2013 at 08:31:27pm

From what I gather, this is the sort of thing you need.

9.85 @ 145mph

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

8th Nov, 2013 at 09:54:35pm

Paul look at the old 2wire idle valve driver circuits in the manual. Great big TIP122? Fet can sink some decent amps and larger ones are avaliable or could be paralelled, you might need to choose a slightly less meaty motor. I would also perhaps add a smoothing cap to the output but nothing too big. Im sure thats what they used anyways, been a while:(. turbo 16v k-series 11.9@118.9 :)

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

9th Nov, 2013 at 10:25:51am

Paul, what's your maximum current (ie if PWM reached 100%) or is that unknown because of the load on the motor being uncertain ?

Edited by Rod S on 9th Nov, 2013. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 11:04:04am

This is the starter motor from which the motor has been stripped:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

9th Nov, 2013 at 11:15:38am

I'm no electronics buff, so not sure.

9.85 @ 145mph

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 11:20:33am

Actually the starter could be the same as one of these:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

9th Nov, 2013 at 11:31:00am

13Hz sounds very low (the bigger the motor, the lower the frequency used is a general rule, but 13Hz does seem low...)

Edited by Rod S on 9th Nov, 2013. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 12:03:18pm

The MS3 can output up to 78Hz, if that helps.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

9th Nov, 2013 at 12:27:38pm

what about RC place/car drivers? they handle serious currents. Still think your a little "over motored" and a lighter motor designed for 100% duty may be a better place to start. A mobility scooter drive motor perhaps? even then i cant help but feel its a bit much but i know you will have thought long and hard about the drive power required for the pump so i should probably shoosh lol turbo 16v k-series 11.9@118.9 :)

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 12:35:42pm

The motor is bigger than I need but it is free out my bin of abandoned projects.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

9th Nov, 2013 at 12:37:04pm

On 9th Nov, 2013 Paul S said:

I like the idea of the MOSFET driver, but I'm still unsure if I can put one on the 12v side of the motor? Ooops, my bad.... I just did a quick search for power Mosfets - the average Mosfet is N-channel (just like the average transistor is NPN) - to drive on the 12V side needs a P-channel. Not so common. There are a few available with adequate current rating but not with great power dissipation ratings. I need to look at a few datasheets to be sure. If you get the optimum PWM frequency for the chosen motor (it can be calculated from the winding inductance etc. if you know it or can measure it (not easy)) the power disipation shouldn't be a problem. Driver circuit would need to be different for a P-channel as well but shouldn't be a problem. But, as Denis says, perhaps a better choice of motor ? EDIT - missed your comment above re. motor.... Edited by Rod S on 9th Nov, 2013. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 01:01:51pm

You can pick up a recon starter including the motor for £30:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 01:10:12pm

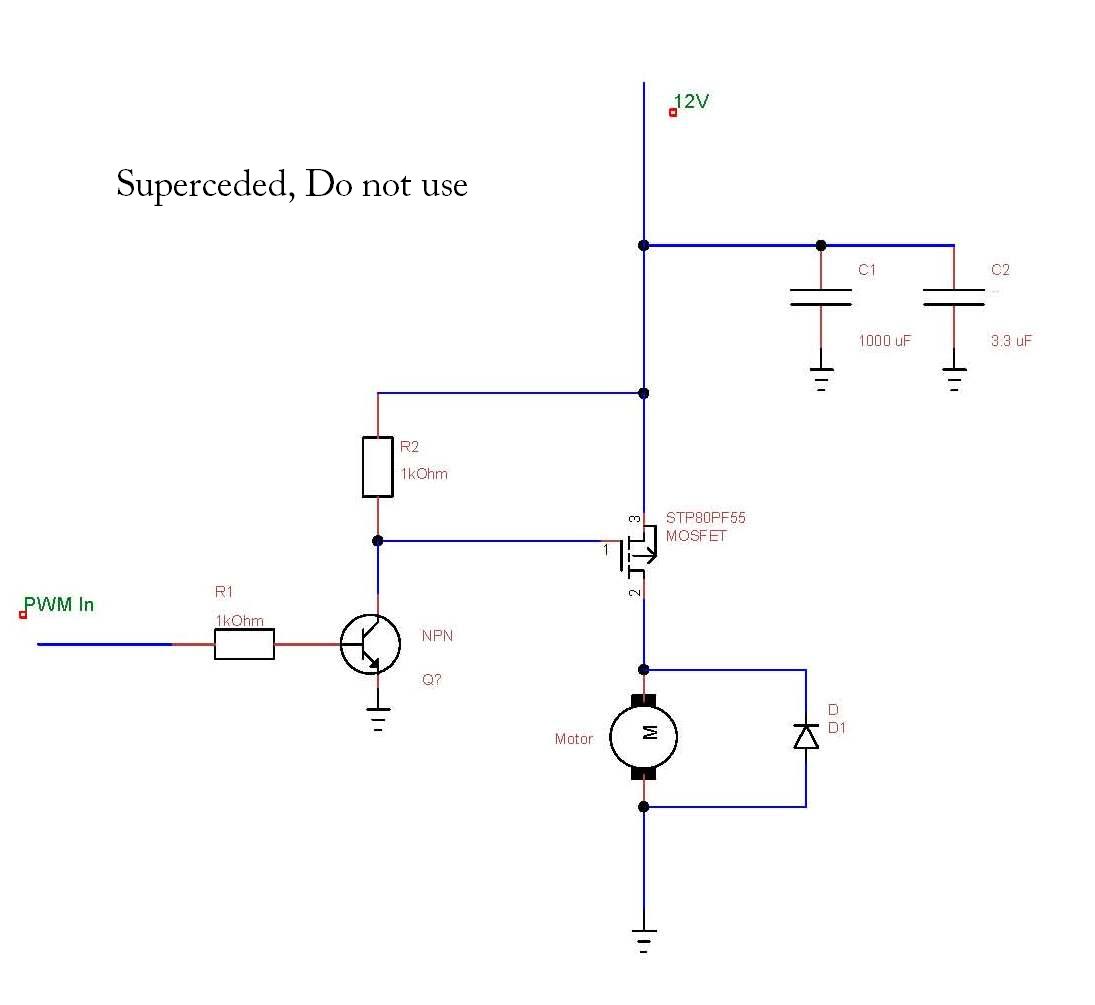

P-channel MOSFET 80A :

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

9th Nov, 2013 at 03:18:27pm

Automotive stuff?

turbo 16v k-series 11.9@118.9 :)

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

9th Nov, 2013 at 05:02:17pm

Denis,

Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

9th Nov, 2013 at 06:00:13pm

How about this for starters:

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

2909 Posts Member #: 83 Post Whore Glasgow, Scotland |

9th Nov, 2013 at 07:44:25pm

Forgive my ignorance but why cant you use n channel devices? The wiring difference is trivial turbo 16v k-series 11.9@118.9 :)

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

9th Nov, 2013 at 08:42:21pm

This would be how I would modify what you posted:

Edited by jbelanger on 9th Nov, 2013. |

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

10th Nov, 2013 at 07:49:45am

On 9th Nov, 2013 evolotion said:

Forgive my ignorance but why cant you use n channel devices? The wiring difference is trivial Denis, Because an N-channel needs a positive gate voltage so has to go between the load and ground (otherwise the gate current would have to go through the load which, in this case, has both resistance and inductance which will be all over the place because of the back EMF motors create). Just like injector drivers and anything else that has the power permantly applied and is "switched" on the ground side, allways N-channel or NPN. Paul can't do that (easily) as the negative side of the motor windings are connected to the case. To switch on the 12V side needs P-channel where the gate voltage is reversed. With that criteria, and the benefit of hindsight, same would have applied to the transistors, they would have had to be TIP42 or similar, ie, PNPs. Paul/Jean, I agree with Jean's version except for one thing I don't understand - moving the flyback diode to across the FET. According to the datasheet the package has an internal diode ??? Re. the R2, yes, 100ohm or less - from what I've read these high power Mosfets have a high gate capacitance so the initial gate current has to be high for them to switch cleanly. To that end, also make sure the resistor has a reasonable power rating (without doing the maths I would guess at 1/2 or 1 W) and the drive transistor is good for 1 - 2 A (ie a ZTX450 or better). EDIT - and I agree with Jean about using a couple or more of them. You would exceed the rating of a single one if you approached 100% PWM and their power dissipation isn't as good as the N-channel equivilants plus you will most likely have to mount them on micas (or the more modern silicon) insulators - the datasheet isn't clear what terminal the heat sink tab is common with (it might be isolated but normally there is an additional letter after the TO-220 if it is) but most likely common with pin 2. Edited by Rod S on 10th Nov, 2013. Schrödinger's cat - so which one am I ??? |

||||||

|

8604 Posts Member #: 573 Formerly Axel Podland |

10th Nov, 2013 at 09:53:03am

Thanks guys.

Saul Bellow - "A great deal of intelligence can be invested in ignorance when the need for illusion is deep."

|

||||||

(2)[/url] by [url=https://www.flickr.com/photos/150672766@N03/]Rod Sugden[/url], on Fli) 5988 Posts Member #: 2024 Formally Retired Rural Suffolk |

10th Nov, 2013 at 10:28:56am

Mounting - ideally on a purpose made PCB (we can think about that later) but the main thing is to support the legs relative to the bolt/heatsink hole so, for a test, what I would suggest is a bit of veroboard with a nice slab of 1/8" (3mm) aluminium down one side - visualise the standard MS3 board and its simple heatsink but make it larger. And remove the copper from the veroboard where the bolts go through.

Schrödinger's cat - so which one am I ??? |

||||||

|

3588 Posts Member #: 655 Post Whore Northern Ireland |

10th Nov, 2013 at 10:51:52am

4mm would be more than ample, and with proper PWM control, current should actually be much lower as the pump is never really running at max effort 9.85 @ 145mph

|

||||||

|

1267 Posts Member #: 831 Post Whore Montreal, Canada |

10th Nov, 2013 at 06:20:56pm

Rod, Paul,

|

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

10th Nov, 2013 at 07:05:25pm

working back from a 125amp draw on my starter motor at 11.5v would confirm the 1.4KW but remember that when the alternator is producing, the voltage is ~14.5v so urrent will be more like 95amps at full load. also taking into consideration the pump power absorption without the fan has been estimated at 1.5hp which is more like 75amps at 14.5v

On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

| Home > A-Series EFI / Injection > DC Motor Control from ECU ??? | |||||||

|

|||||||

| Page: |