| Page: |

| Home > Show Us Yours! > K1100 turbo track car build | |||||||

539 Posts Member #: 6807 Post Whore York |

29th Mar, 2013 at 01:47:11am

Well, where to start, bit of history:

Edited by adcyork on 13th Nov, 2021. |

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

29th Mar, 2013 at 07:43:58am

nice bit of fab work there.

|

||||||

|

8215 Posts Member #: 90 Post Whore Somewhere around Swindon |

29th Mar, 2013 at 09:06:55am

looking good, you could make your own manifold but i doubt its worth it Crystal Sound Audio said:

Why wolfie...you should have your name as Fuckfaceshithead ! "A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools."-Douglas Adams |

||||||

539 Posts Member #: 6807 Post Whore York |

29th Mar, 2013 at 09:29:04am

On 29th Mar, 2013 wolfie said:

looking good, you could make your own manifold but i doubt its worth it I'm not really in the game for making one. I don't have a tig welder for one. I'm sure I saw that sprocket had got a maniflow manifold? |

||||||

|

432 Posts Member #: 2726 Senior Member wakefield |

29th Mar, 2013 at 10:56:20am

I keep been tempted to do a k head. Wot kit u gonna use?

|

||||||

359 Posts Member #: 8931 Senior Member Herefordshire |

29th Mar, 2013 at 02:01:05pm

Looks like a great project Edited by Billus89 on 29th Mar, 2013. |

||||||

539 Posts Member #: 6807 Post Whore York |

31st Mar, 2013 at 12:30:50pm

On 29th Mar, 2013 adrian said:

I keep been tempted to do a k head. Wot kit u gonna use? Adrian I've got the force racing kit ready to go on. It all looks lovely and the anodising on the parts seems top notch. Edited by adcyork on 31st Mar, 2013. |

||||||

|

8215 Posts Member #: 90 Post Whore Somewhere around Swindon |

31st Mar, 2013 at 12:38:13pm

Its worth doing a little more to that bulkhead box and chop off the right hand corner to allow more room around the actuator

Crystal Sound Audio said:

Why wolfie...you should have your name as Fuckfaceshithead ! "A common mistake that people make when trying to design something completely foolproof is to underestimate the ingenuity of complete fools."-Douglas Adams |

||||||

|

4018 Posts Member #: 1757 Back to Fucking Tool status Swindon |

31st Mar, 2013 at 04:48:15pm

I belive he is running it in N/A form not turbo, plus with the khead you dont need a bhb, one like that would be perfect for an external wastegate and down pipe.

Drives

|

||||||

178 Posts Member #: 10196 Advanced Member |

31st Mar, 2013 at 08:28:38pm

iirc i think maniflow do list a k head manifold on there site |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

31st Mar, 2013 at 08:32:34pm

yep 249 quid for a steel one On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

12307 Posts Member #: 565 Carlos Fandango Burnham-on-Crouch, Essex |

31st Mar, 2013 at 08:33:01pm

yep 249 quid for a steel one On 28th Aug, 2011 Kean said:

At the risk of being sigged... Joe, do you have a photo of your tool? http://www.turbominis.co.uk/forums/index.p...9064&lastpost=1 https://joe1977.imgbb.com/ |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

31st Mar, 2013 at 09:30:48pm

On 29th Mar, 2013 adcyork said:

On 29th Mar, 2013 wolfie said:

looking good, you could make your own manifold but i doubt its worth it I'm not really in the game for making one. I don't have a tig welder for one. I'm sure I saw that sprocket had got a maniflow manifold? Aye, Maniflow. I had them make one with the downpipes 3/8" shorter. whether it was or not I'll never know since I don't have another to compare lol. It's in Mild steel though, but at the very least it has everything in the right place and it's the right shape

On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

539 Posts Member #: 6807 Post Whore York |

31st Mar, 2013 at 11:04:11pm

On 31st Mar, 2013 Paul R said:

I belive he is running it in N/A form not turbo, plus with the khead you dont need a bhb, one like that would be perfect for an external wastegate and down pipe. Btw wheel are looking good  I am running it NA yes, at first anyway. I was aware that you could get away without a bhb with the k conversion but i thought it best to stick one in while i was there incase any complications with packaging arise later |

||||||

539 Posts Member #: 6807 Post Whore York |

31st Mar, 2013 at 11:23:09pm

What made you go for the 3/8" shorter pipe? To get it up higher in the tunnel?

On 31st Mar, 2013 Sprocket said:

On 29th Mar, 2013 adcyork said:

On 29th Mar, 2013 wolfie said:

looking good, you could make your own manifold but i doubt its worth it I'm not really in the game for making one. I don't have a tig welder for one. I'm sure I saw that sprocket had got a maniflow manifold? Aye, Maniflow. I had them make one with the downpipes 3/8" shorter. whether it was or not I'll never know since I don't have another to compare lol. It's in Mild steel though, but at the very least it has everything in the right place and it's the right shape  |

||||||

|

4309 Posts Member #: 1321 Post Whore Wiltshire |

1st Apr, 2013 at 11:21:21am

I have looked at the mass market manifolds and they do seem to hang down low for very low road car. not an issue if your running sightly lowered but could be for a very low car.

On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

539 Posts Member #: 6807 Post Whore York |

11th Apr, 2013 at 09:01:31pm

Progress is slow with doing overtime at work, frustrating!

|

||||||

539 Posts Member #: 6807 Post Whore York |

18th Apr, 2013 at 10:14:52pm

Bit more progress this eve.

Edited by adcyork on 18th Apr, 2013. |

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

19th Apr, 2013 at 01:16:27pm

keep up the good work. |

||||||

2406 Posts Member #: 341 aka T2clubby South Staffs |

19th Apr, 2013 at 03:42:01pm

Heat gun and scraper does the job |

||||||

539 Posts Member #: 6807 Post Whore York |

20th Apr, 2013 at 05:52:36pm

Well, the ATB turned up yesterday, thanks again to John, top job!

|

||||||

539 Posts Member #: 6807 Post Whore York |

19th Aug, 2014 at 01:43:13pm

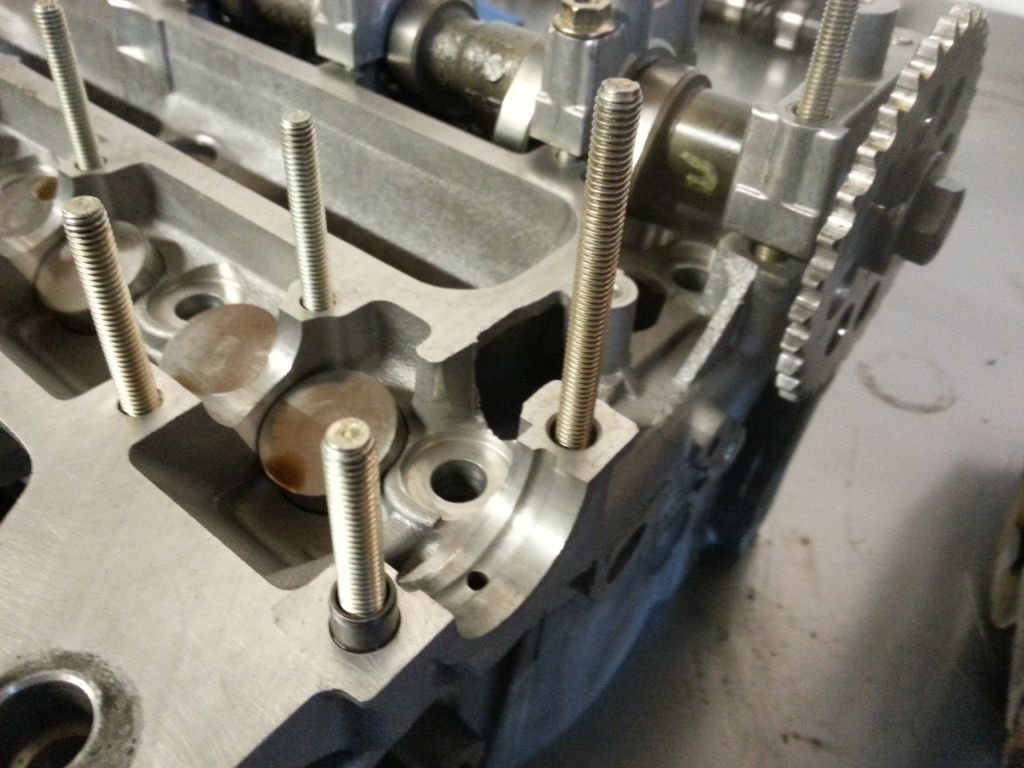

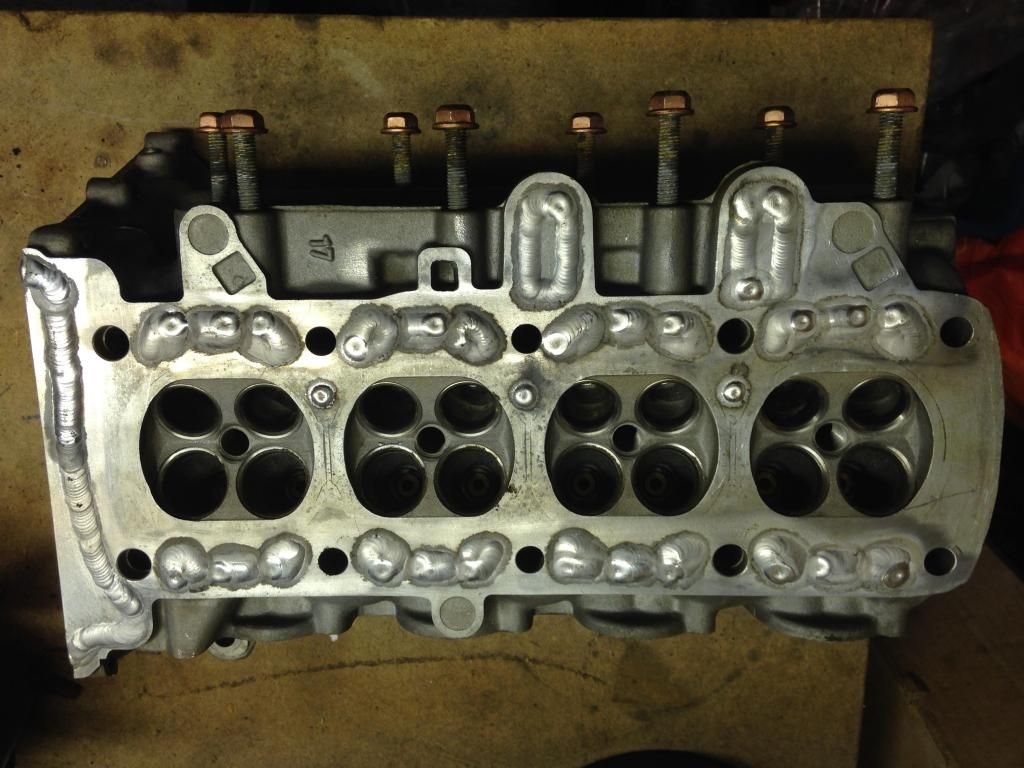

It's been a while...

Edited by adcyork on 19th Aug, 2014. |

||||||

218 Posts Member #: 9213 Senior Member Scotland |

19th Aug, 2014 at 02:43:34pm

looking good! all looks very familiar |

||||||

1030 Posts Member #: 1291 Post Whore Suffolk / Birmingham |

19th Aug, 2014 at 04:15:56pm

Do motorworks not have any spring seats?

|

||||||

539 Posts Member #: 6807 Post Whore York |

19th Aug, 2014 at 05:12:26pm

On 19th Aug, 2014 nky_84 said:

looking good! all looks very familiar  . i've been racing in mod prod for last 2 years with a broadly similar setup . i've been racing in mod prod for last 2 years with a broadly similar setup

Did you do the alloy welding or get it done professionally? How much did it cost? Sounds good, what running gear set up are you running in that class? I don't have an AC tig set so I got a mate to do it at M-sport on his dinner because he was able to preheat it aswell. £30. It seems that there are plenty of places that will do it for only slightly more though. Slater - motorworks is the same price as new from bmw and I need to buy my new followers from them anyway. I do need to tap them up about a set of LT cams soon though. Edited by adcyork on 19th Aug, 2014. |

||||||

| Home > Show Us Yours! > K1100 turbo track car build | |||||||

|

|||||||

| Page: |