| Page: |

| Home > Show Us Yours! > brads 1963 mk1 850. | |||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

21st Dec, 2012 at 02:35:45am

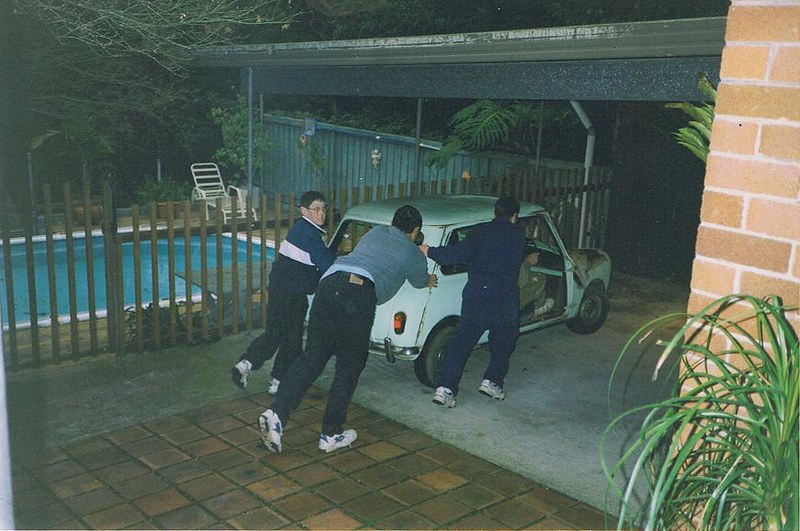

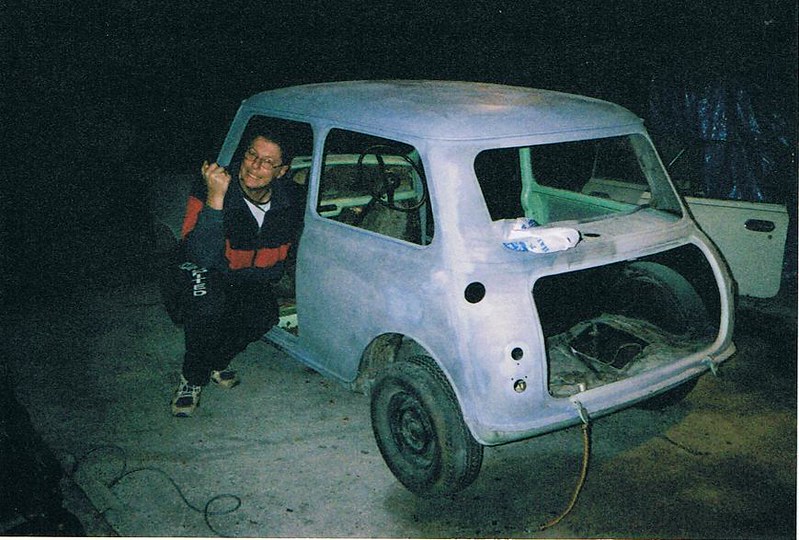

Hi guys

Edited by braad on 12th Dec, 2016. |

||||||

118 Posts Member #: 9965 Advanced Member Sydney, Australia! |

21st Dec, 2012 at 05:21:12am

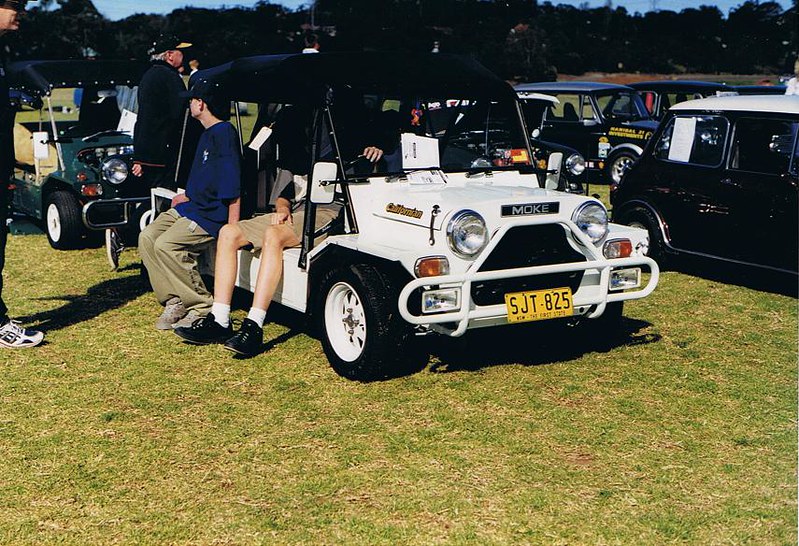

Hey look, its Willys moke!

ďA turbo: exhaust gasses go into the turbocharger and spin it, witchcraft happens and you go faster.Ē - Jeremy Clarkson |

||||||

|

9258 Posts Member #: 123 Post Whore Betwix Harrogate and York |

21st Dec, 2012 at 08:16:42am

Good stuff. My hillclimber has essentially been with me in 1994 (a bit like triggers brush!!), it's good to have long term projects.

Fastest 998 mini in the world? 13.05 1/4 mile 106mph

On 2nd Jan, 2013 fastcarl said:

the design shows a distinct lack of imagination, talk about starting off with a clean sheet of paper, then not bothering to fucking draw on it,lol On 20th Apr, 2012 Paul S said:

I'm mainly concerned about swirl in the runners caused by the tangential entry. |

||||||

4625 Posts Member #: 20 My sister is so fit I won't show anyone her picture Lake District |

21st Dec, 2012 at 06:24:36pm

Nice writeup, good luck with your project. |

||||||

4890 Posts Member #: 1775 Post Whore Chester |

22nd Dec, 2012 at 10:53:13am

Nice write upand good luck for your 2013 plans I run a supercharger and I don't care the TB is on the wrong side.

|

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

24th Dec, 2012 at 05:18:12am

On 21st Dec, 2012 mattsmadmini said:

Hey look, its Willys moke! :) Looking.good Brad! Hey matt, do you know Willy? it's a bloody nice moke seeing from his thread! Do you know if the colour was from the corvette Z06? On 21st Dec, 2012 wil_h said:

Good stuff. My hillclimber has essentially been with me in 1994 (a bit like triggers brush!!), it's good to have long term projects. Turbo plans sound good, all the info you need here. wow, 18 years with the one car! The thought had come up to make this a pure racer, but I always wanted it on the road. There aren't enough minis on the roads here! not sure i know what triggers brush is though?? There so much information here it's going to get a bit hectic decifering whats useful, upto date and needed! I plan to just bombard with questions if i can't find what i need

On 21st Dec, 2012 Turbo Phil said:

Nice writeup, good luck with your project.  On 22nd Dec, 2012 gr4h4m said:

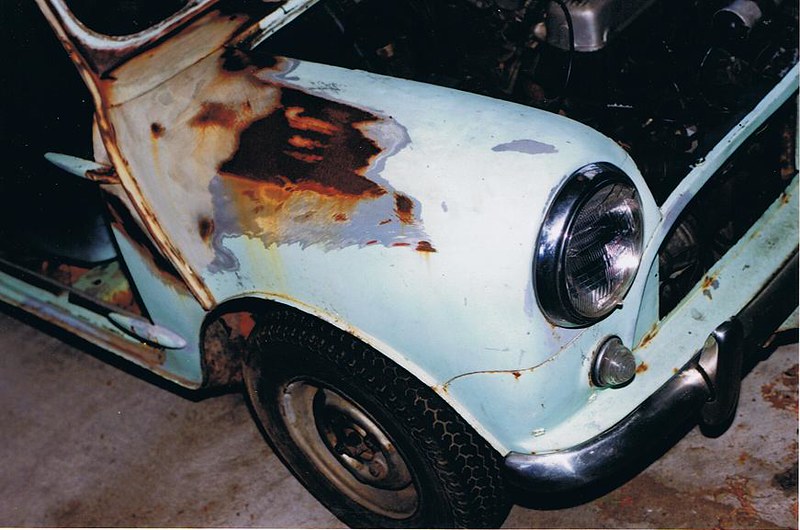

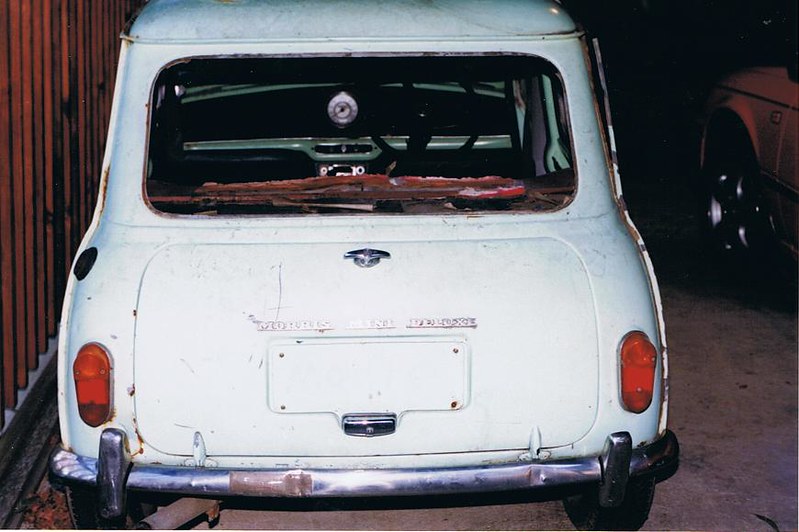

Nice write upand good luck for your 2013 plans Thank you guys for the words of encouragement! Unfortunately my mechanics shop has shut up for christmas and he hadn't managed to replace the bearings in my top arms yet! Knowing him though, he might do it in his "break" as he loves minis and it would be pretty easy with all the proper tools and presses. I'm hoping this is the case, as i'd love to build the front subframe up soon. Everything needs finalising and painting I uncovered the car the other day and found a heap of new surface rust across the front so attacked that and etch primered it. the car has an old pool liner and then a car cover. interestingly there was a defined line of rust where the pool liner started (no rust under liner, just the car cover). I assumed with our heat and humidty in Australia the pool liner may have trapped water/condensation...seems not! before

and after (i didn't get to finish the drivers side edge of valance)

Found a hole heading into the sill from the wheel well. it's hard to see in this pic, but it's there!

P.s. AGAIN, sorry for the pics, i did rotate them before uploading to imageshack, and once again in imageshack, but to no success :( |

||||||

118 Posts Member #: 9965 Advanced Member Sydney, Australia! |

25th Dec, 2012 at 07:32:07am

On 24th Dec, 2012 braad said:

On 21st Dec, 2012 mattsmadmini said:

Hey look, its Willys moke! :) Looking.good Brad! Hey matt, do you know Willy? it's a bloody nice moke seeing from his thread! Do you know if the colour was from the corvette Z06? i do, we chat a bit, he lives in rAdelaide, tis a gorgeous machine, and has won many awards for it... i just wish my little wheeler moke would ever be that nice... and yes, his red is the wonderful corvette red.... perdy init? ďA turbo: exhaust gasses go into the turbocharger and spin it, witchcraft happens and you go faster.Ē - Jeremy Clarkson |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

27th Dec, 2012 at 01:54:52am

On 25th Dec, 2012 mattsmadmini said:

On 24th Dec, 2012 braad said:

On 21st Dec, 2012 mattsmadmini said:

Hey look, its Willys moke! :) Looking.good Brad! Hey matt, do you know Willy? it's a bloody nice moke seeing from his thread! Do you know if the colour was from the corvette Z06? i do, we chat a bit, he lives in rAdelaide, tis a gorgeous machine, and has won many awards for it... i just wish my little wheeler moke would ever be that nice... and yes, his red is the wonderful corvette red.... perdy init? Its extremely perdy! I am not surprised that it has won many awards. Its just so fucking classy

I'll be ordering some 10x6 wheels from www.midlandwheels.com in the next few days. I'm just undecided as to whether i should go for mambas (i've wanted them for years) or minilite. Both in a black centre & with A008's What are peoples thoughts on the two options? Maybe i should do a poll haha |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

28th Dec, 2012 at 07:59:34am

the wheels for everyones viewing

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

28th Dec, 2012 at 08:55:13am

Mamba 10x6 black with A008's i think |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

28th Dec, 2012 at 10:03:17am

On 28th Dec, 2012 Turbo This.. said:

Mamba 10x6 black with A008's i think thanks mate, i'm leaning that way. It's just the minilite style is so synonymous with the mini! I wont be buying wheels for it again, so i don't want to regret the decision in 12 months time haha I see you're from brisbane! awesome mate, it's good to see some aussies on here

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

28th Dec, 2012 at 10:29:21am

yeah know how that is i bought 13" now i want smaller so restoring some 12" ones Edited by Turbo This.. on 28th Dec, 2012. |

||||||

|

Forum Mod  5933 Posts Member #: 784 9 times Avon Park Class C winner Milton Keynes |

28th Dec, 2012 at 10:32:19am

If you like the Mambas why not go for Carl's 3 piece replicas - they look awesome I seriously doubt it! |

||||||

|

432 Posts Member #: 7856 Senior Member Essex |

28th Dec, 2012 at 10:56:36am

I would say Mamba's from them two options, or as Paul said, the Force racing replica's. |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

29th Dec, 2012 at 03:09:11am

On 28th Dec, 2012 paul wiginton said:

If you like the Mambas why not go for Carl's 3 piece replicas - they look awesome Thanks for the input Paul! On 28th Dec, 2012 Amp said:

I would say Mamba's from them two options, or as Paul said, the Force racing replica's. Thanks for your comments mate, they're appreciated. Well guys, Carls modular mambas are an awesome looking wheel, but they're £100 more each wheel! so thats another £400 (which is another $AU600). I really do love 3-piece wheels, as i have had them before on other cars here. Our best known 3-piece wheel maker would be 'Simmons', who made great wheels (before being bought out). I was fortunate enough to build & repair some sets of 15" - 18" wheels. Unfortunately just too expensive for me! I think i will go the mambas. I don't think you can go wrong with mambas on a mini :) |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

29th Dec, 2012 at 03:32:30am

On 28th Dec, 2012 Turbo This.. said:

yeah know how that is i bought 13" now i want smaller so restoring some 12" ones What 13's do you have? Are you thinking of selling them? |

||||||

6729 Posts Member #: 618 Post Whore Glasgow |

29th Dec, 2012 at 01:18:39pm

i'd go for the mambas. I have a particular dislike for most of the minilights on the market these days |

||||||

478 Posts Member #: 9269 Senior Member Rotherham |

29th Dec, 2012 at 11:53:21pm

I go mambas from Carl Craig

|

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

1st Jan, 2013 at 03:11:45am

On 29th Dec, 2012 Rob Gavin said:

i'd go for the mambas. I have a particular dislike for most of the minilights on the market these days Yeah i went the mambas, Ordered them last night (Australian time) to claim the 20% they were having at Midlandwheels. So i ordered the 10x6 mambas with A008s I'm not sure how long they will be with NYE and all of that, but i can say that i am a bit excited

On 29th Dec, 2012 dig-mini said:

I go mambas from Carl I like them too, but too expensive for me. They need to be flown across the world so postage is a killer |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

13th Jan, 2013 at 05:55:49am

Alright peeps! my mambas have arrived, 10x6 with A008s

|

||||||

1767 Posts Member #: 9165 Previously josh4444 Australia, brisbane |

13th Jan, 2013 at 07:30:56am

nice |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

5th Feb, 2013 at 06:00:35am

thanks mate

Edited by braad on 5th Feb, 2013. |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

8th Mar, 2013 at 03:51:39am

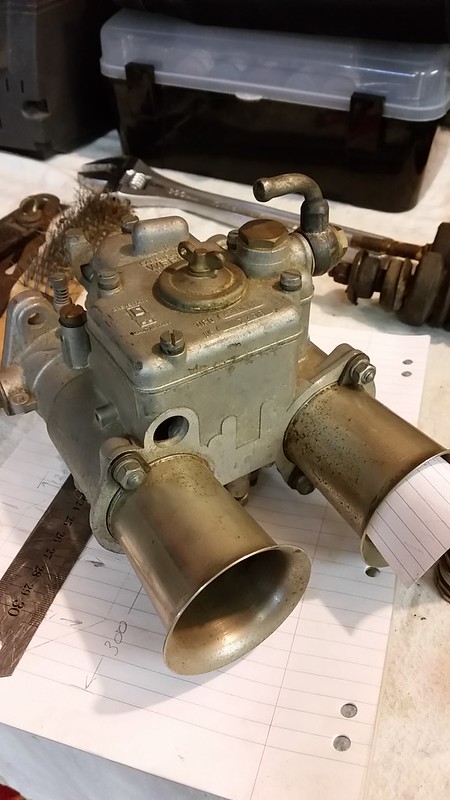

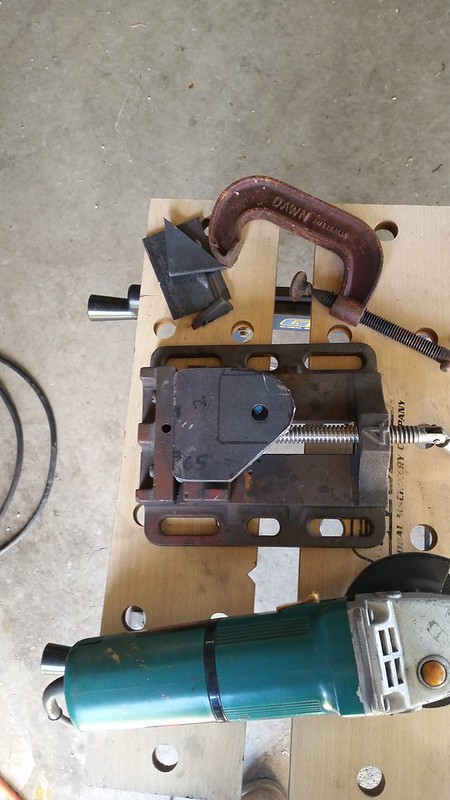

well there have been a few little updates, minor but important!

|

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

19th Feb, 2015 at 03:37:45am

On 8th Mar, 2013 braad said:

I dropped my 'S' hubs, drive hubs, wheel studs, CV's and discs off today to get renewed with new wheel bearings, balljoints adjusted and wheel studs. All spaced properly and rebuilt. All the splines and surfaces are nice, neat and unscored/undamaged BOOYAH! it's slowly coming along. So very slowly it seems... still havent got the CV's, hubs etc back yet. Mechanics had a few bouts of bad health. Hopefully now that he's back on the mend they come back soon. So lifes taken a turn (for the better), i broke up with the ex and sold our house etc. Moved back home, got a new girl and travelled to bits of Europe (anyone from Australia knows thats a big trip!). now that im back and rebuilt the finances the directions changed a bit and this year has been declared the year of the mini, with full backing of the new gf and family. The mambas were sold off to another mini owner in Tasmania, Australia. In due time i will get some force racing 3-piece 10" wheels (inner and outer widths TBD when i can measure it all up, but aiming for 6.5 or 7" wide). The body is booked in for a 6-point rollcage (FIA/CAMS approved) on march 30th, then after that i would like it to head off for some bodywork. This is where i need help here. Over here in Australia mini people seem to frown a bit at anything too over the top bodywork wise, so tubbing the arches is something not seen often on street minis. I hope to draw on the collective brains trust of turbominis to help me with elements which are a bit different to us Aussies. Anyway, there wont be too much to report until the rollcage is done. Between now and then i just have to weld up a jig/frame for the body and just plan. cheers guys & girls |

||||||

140 Posts Member #: 10115 Advanced Member Sydney, Australia |

22nd Mar, 2015 at 02:53:52am

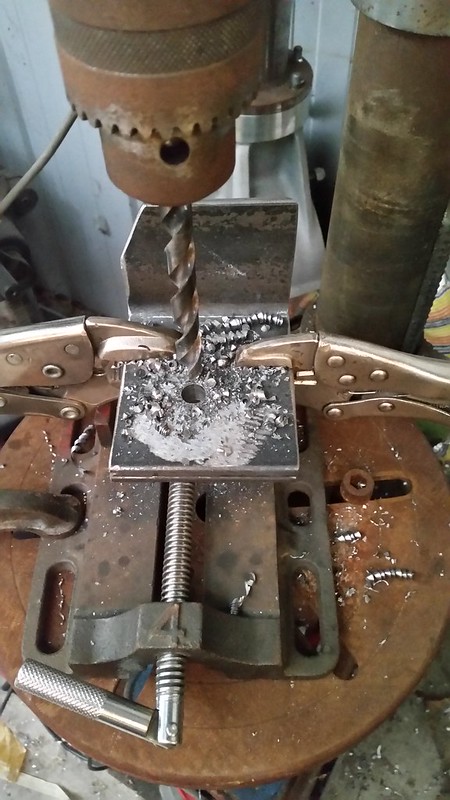

So the cars going for rollcage next saturday 28th at AGI. To help with mobility i made up a little trolley. Should be useful for some other work too as its a bit higher, a little more ergonomic :lol:

|

||||||

| Home > Show Us Yours! > brads 1963 mk1 850. | |||||||

|

|||||||

| Page: |