| Page: |

| Home > Show Us Yours! > k1200rs 1380 engine build | |||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:35:36am

Well, I have finally made a start, after a bit of running around to find some cost iron rod and 3/8unc die for plugging the head bolts, 1/4 cast iron plugs and 1/8 brass plugs along the buying threading taps to match, so I can block the water and oil ways

Edited by philc on 27th Jul, 2010. |

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:40:54am

moderators, please delete. thanks |

||||||

9502 Posts Member #: 1023 Post Whore Doncaster, South Yorkshire |

27th Jul, 2010 at 08:03:45am

if you take the " width=640 height=480" out of the img code (ie [img]) the pics should show Yes i moved to the darkside |

||||||

361 Posts Member #: 114 Senior Member Porto/Portugal |

27th Jul, 2010 at 11:04:05am

Pedro Silva

|

||||||

7265 Posts Member #: 1268 The Boom Boom speaker Police! Essex |

27th Jul, 2010 at 11:06:49am

Edit: pah! Beaten to it! Edited by theoneeyedlizard on 27th Jul, 2010. In the 13's at last!.. Just |

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:38:15pm

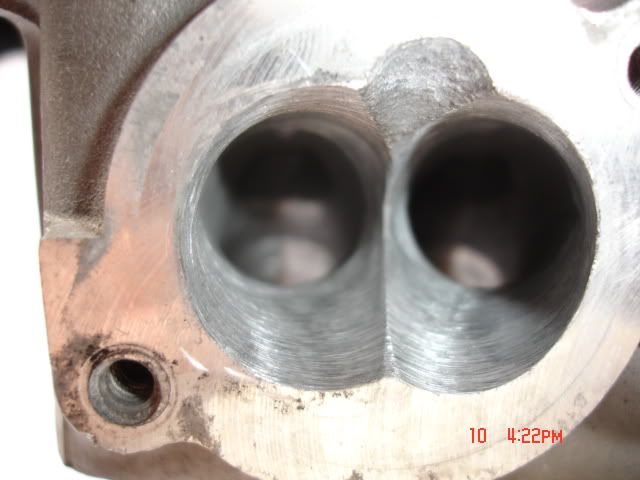

block has come back from the machine shop with its first skim and a good old dip in acid

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:41:12pm

Some more progress made yesterday and a big thanks to Martin at MJA engineering in Bromsgrove for letting me use his machines and the use of his time.

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:43:59pm

More progress made, drilling and tapping block for stud and blanks off the water ways

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:46:09pm

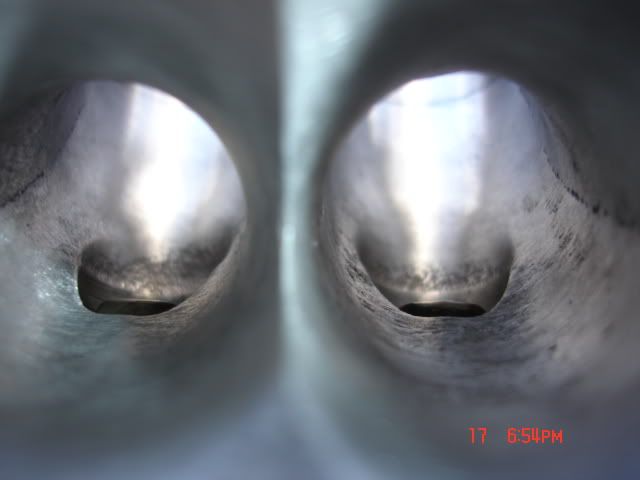

Bit more to update, started to do a little porting, just to sharpen up the edges, just need polishing now

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:48:23pm

Completed a bit more today, had all of the holes welded on the head, so ready for dry deck

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

27th Jul, 2010 at 07:50:16pm

Not a lot done yesterday, head had its first basic skim, to remove the weld, I did not realise how much ali heads distort, though not too much on mine, as JK says in his build guide 'note the shadows' :laughing7:

|

||||||

1137 Posts Member #: 1450 Post Whore Near Paris - France |

27th Jul, 2010 at 08:03:49pm

Offset bored to match the head ? Rusty by nature

On 23rd Jun, 2008 paul wiginton said:

They said "That sounds rough mate." I said "Cheers it cost me a fortune to make it sound like that!" |

||||||

|

4304 Posts Member #: 1321 Post Whore Wiltshire |

27th Jul, 2010 at 08:11:54pm

Nice project. Is this to be turbo'd? On 7th Oct, 2010 5haneJ said:

yeah I gave it all a good prodding |

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

28th Jul, 2010 at 08:19:10pm

On 27th Jul, 2010 Advantage said:

Offset bored to match the head ? possibly, however, my understanding from sprocket is the bore will need lining then moving over, or something similar On 27th Jul, 2010 minimole23 said:

Nice project. Is this to be turbo'd? sadly not, i think too much of an expense on this one, but happy with n/a hoping to get a good power out put and good driveability |

||||||

11046 Posts Member #: 965 Post Whore Preston On The Brook |

28th Jul, 2010 at 10:08:20pm

you cant really offset bore to line up the chambers in the head on a 1380, it really would have to be a custom head gasket, and then we also start getting to the point of bore wall thinness akin to a 74.7mm bore, THIN!!

Edited by Sprocket on 28th Jul, 2010. On 26th Oct, 2004 TurboDave16v said:

Is it A-Series only? I think it should be... So when some joey comes on here about how his 16v turbo vauxhall is great compared to ours, he can be given the 'bird'... On 26th Oct, 2004 Tom Fenton said:

Yep I agree with TD........ |

||||||

|

54 Posts Member #: 8863 Advanced Member Wiltshire |

29th Jul, 2010 at 09:22:29pm

Also offsetting the bores seems like a massive amount of work considering performance people are already getting without such measures :)

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

4th Aug, 2010 at 08:01:55pm

So, have decided that the head bolts I have drilled and tapped where crap, so ran around yesterday to find some 16mm cast iron bar, no chance, could only get 30mm for £14, which needed to be turned down for a 14mm tap. So I have spent the morning turning that down, very boring and tapping it with a 14mm die.

|

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

4th Aug, 2010 at 08:28:30pm

Looks good. How did you tidy up the extra metal on the plugs? Hacksaw or something more exotic? I've got the same to do to my block and head for dry deck. On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

4th Aug, 2010 at 09:55:31pm

On 4th Aug, 2010 apbellamy said:

Looks good. How did you tidy up the extra metal on the plugs? Hacksaw or something more exotic? I've got the same to do to my block and head for dry deck. the old faithful grinder, just be careful not to slip and cut too much off the surface of the block. do it as close as you can, less time wasted on skimming |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

5th Aug, 2010 at 09:49:32am

if your dry decking the head why don't you plug the water gallery holes on the block too? Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

5th Aug, 2010 at 09:53:50am

On 5th Aug, 2010 Jimster said:

if your dry decking the head why don't you plug the water gallery holes on the block too? i am just have run out of brass plugs |

||||||

|

Site Admin  9403 Posts Member #: 58 455bhp per ton 12 sec 1/4 mile road legal mini Sunny Bridgend, South Wales |

5th Aug, 2010 at 01:03:35pm

good stuff Team www.sheepspeed.com Racing

On 15th May, 2009 TurboDave said:

I think the welsh one has it right! 1st to provide running proof of turbo twinkie in a car and first to run a 1/4 in one!! Is your data backed up?? directbackup.net one extra month free for all Turbo minis members, PM me for detials |

||||||

16540 Posts Member #: 4241 King Gaycharger, butt plug dealer, Sheldon Cooper and a BAC but generally a niceish fella if you dont mind a northerner Rotherham, South Yorkshire |

5th Aug, 2010 at 02:44:27pm

I'm being tight. I've spent £6 on two lengths of brass bar. I will just spin them down to the right size on the lathe and turn a thread on them. I'll be doing both block and head. On 11th Feb, 2015 robert said:

i tried putting soap on it , and heating it to brown , then slathered my new lube on it

|

||||||

3756 Posts Member #: 1709 I like granny porn. LONDONSHIRE |

5th Aug, 2010 at 03:11:36pm

seems to me this is the 'easy' bit of the 16v conversion,i'd get stuck with all the igntion side of things,

On 2nd Oct, 2009 Vegard said:

On 1st Oct, 2009 Jimster said:

I bet my first wank came quicker than your first mini turbo These new modern turbos with their quick spool up time, would make the competition harder. On 15th Aug, 2011 robert said:

phew!!! thank you brett for smashing in my back doors .( not something i imagined writing... EVER) |

||||||

|

1394 Posts Member #: 1346 Post Whore bromsgrove |

5th Aug, 2010 at 04:20:51pm

On 5th Aug, 2010 apbellamy said:

I'm being tight. I've spent £6 on two lengths of brass bar. . I'll be doing both block and head. I hope not all with brass plugs

|

||||||

| Home > Show Us Yours! > k1200rs 1380 engine build | |||||||

|

|||||||

| Page: |